Method for preparing porous material by physicochemical treatment

A porous material, physical and chemical technology, applied in the field of composite porous material preparation, can solve the problems of solvent molecule residue, porous material channel collapse, etc., to achieve the effect of improving compactness, refining grains, and avoiding residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing a porous material by microwave treatment, which includes the following steps:

[0040] Mix 350g of zinc nitrate, 350g of activated carbon and 350g of solid citric acid at 100°C to obtain a mixture, then add 200mL of ethanol to make the mixture more uniform;

[0041] Adopt 800W microwave to irradiate the mixture for 15min;

[0042] The reaction product was washed 2-3 times with 5L of distilled water, and then centrifuged (at a speed of 3000 rpm for 5 minutes) to obtain a solid product;

[0043] Dry the solid product at 120°C for 4 hours to obtain a specific surface area of 1000m 2 / g of zinc-based composite porous materials.

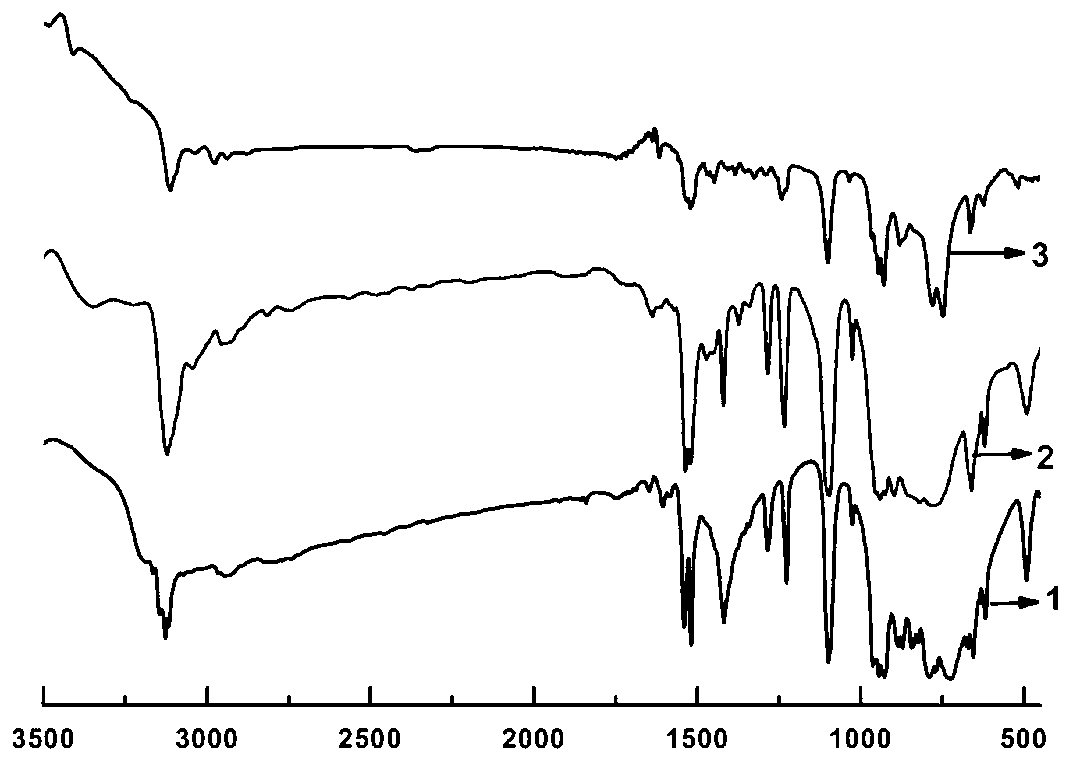

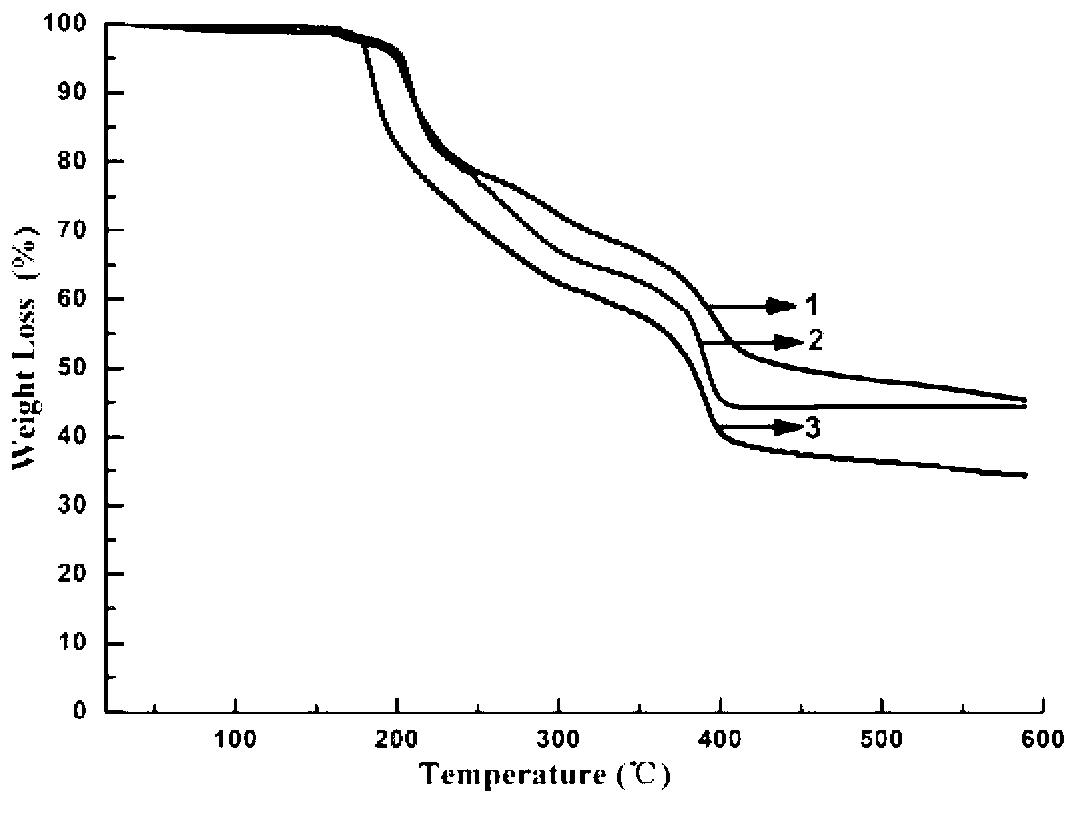

[0044] The infrared spectrum, thermogravimetric TGA analysis results and diffraction patterns of the above-mentioned zinc-based composite porous materials are as follows: Figure 1-3 shown.

[0045] figure 1 It is the infrared spectrum of the zinc-based composite porous material prepared three ...

Embodiment 2

[0049] This embodiment provides a method for preparing a porous material by ball milling, which includes the following steps:

[0050] 350g of copper nitrate, 350g of iron nitrate solid and 500g of tartaric acid are placed in a ball mill to obtain a mixture without adding solvent;

[0051] The mixture was ball milled for 40 minutes, scraped off the solids adhering to the wall of the mixer, and ball milled for 40 minutes to make it evenly mixed;

[0052] Wash the solid product obtained by ball milling with 5 L of water for 2-3 times, and then perform centrifugation (3500 rpm for 5 minutes) to obtain a solid product;

[0053] Dry the solid product at 120°C for 8 hours, then put it into a muffle furnace and bake it at 550°C for 10 hours to obtain a specific surface area of 411m 2 / g copper-iron composite porous material.

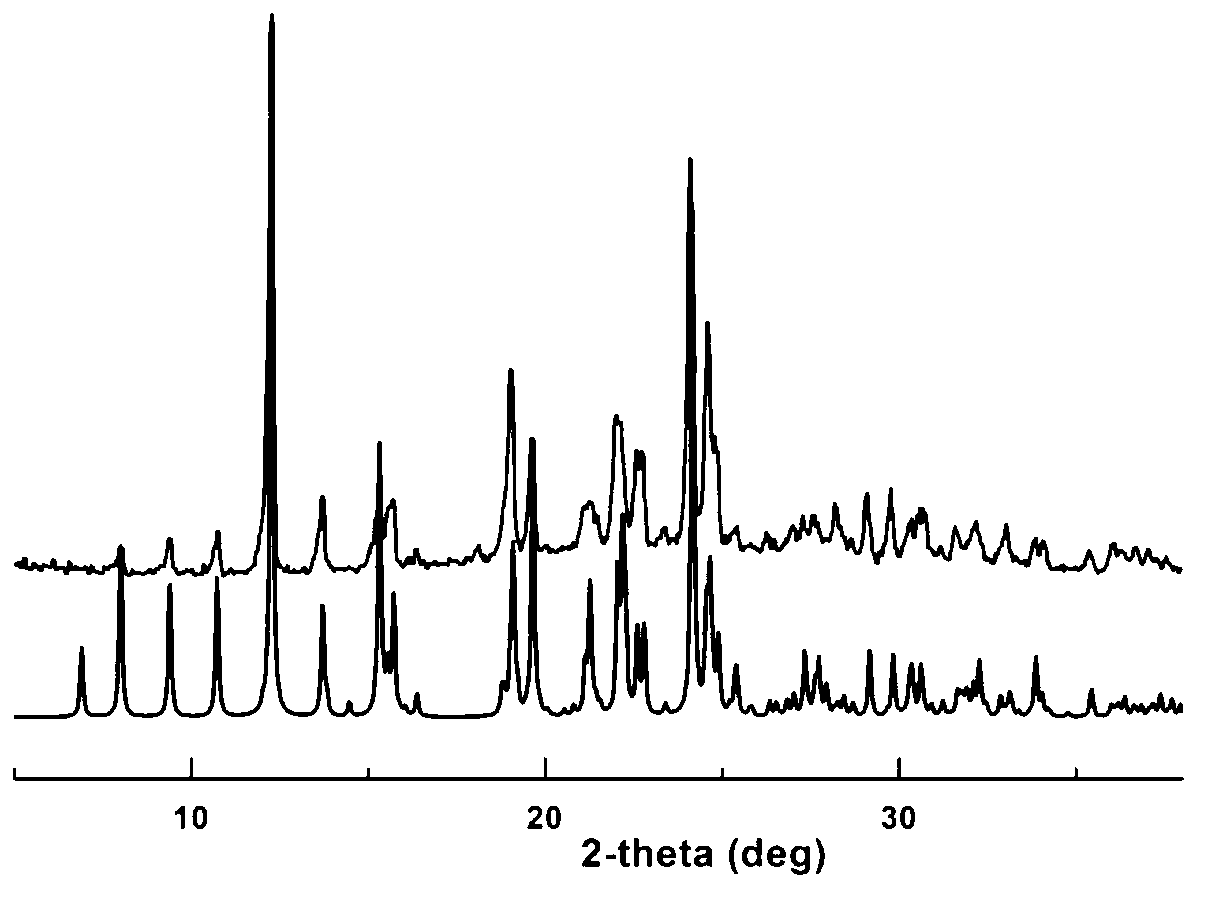

[0054] Figure 4 The powder XRD diffraction and fitting theoretical diffraction patterns of the above-mentioned copper-iron composite porous material, it ...

Embodiment 3

[0057] This embodiment provides a method for preparing a porous material by stirring treatment, which includes the following steps:

[0058] Put 300g of zinc acetate, 500g of aluminum acetate solid, 200g of NaY molecular sieve (activated at 500°C) and 200g of imidazole in a blender, add 300ml of ethanol with a concentration of 95wt%, and mix to obtain a mixture;

[0059] Run the mixer and stir the mixture for 1 hour to fully mix and react the materials;

[0060] The reaction product was washed 3-5 times with 5L of distilled water, and then centrifuged (3000rpm for 5 minutes) to obtain a solid product;

[0061] Dry the solid product at 120°C for 10 hours to obtain a specific surface area of 680m 2 / g calcium-magnesium composite porous material.

[0062] Figure 6 The powder XRD diffraction pattern and the fitted theoretical diffraction pattern of the calcium-magnesium composite porous material prepared for Example 3, it can be seen that the actual diffraction pattern basic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com