O-shaped filter chamber

A filter, U-shaped technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of wasting backwash water, reducing the service life of filter material, and forming blocks, so as to reduce The effect of civil construction area, growth time, and resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

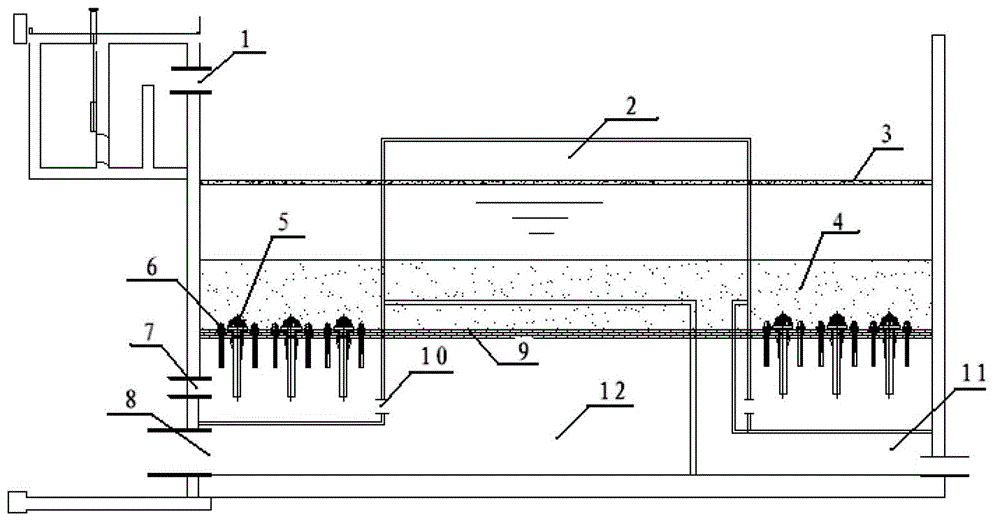

[0030] The present invention is described in detail below in conjunction with the accompanying drawings:

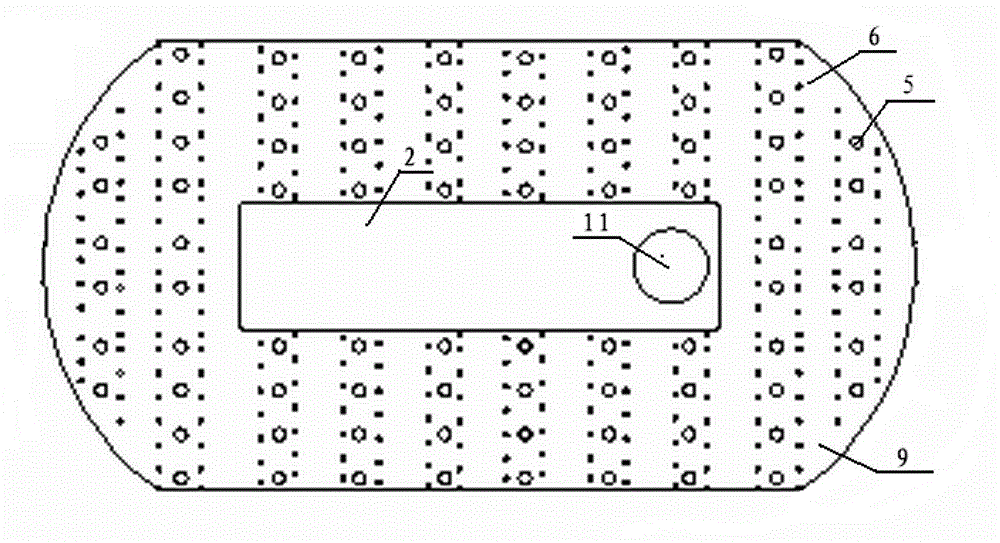

[0031] The present invention includes an O-type filter tank, a water inlet 1 is arranged above the filter tank, and a sewage drain 2 is arranged in the center of the filter tank. The water port 8 is communicated, and the other end is communicated with the sewage outlet 11. A layer of filter material intercepting plate 3 is arranged on the top of the filter tank. Plate 9, a water distribution filter head 5 and a U-shaped air distribution pipe 6 are arranged on the filter plate 9, an air inlet 7 is arranged on the filter tank wall below the filter tank, and the air inlet port 7 is at the water outlet 8 above.

[0032] The water outlet 8 is also a backwash water inlet;

[0033] A water distribution hole 10 is provided on the wall of the sewage channel.

[0034] The U-shaped gas distribution pipe includes a U-shaped cap 13, the open end of the U-shaped cap 13 faces downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com