Improvements relating to fuel economy

A fuel economy and fuel technology, applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of effective amount reduction, difficulty in achieving the optimal balance between fuel economy and exhaust emissions, and reduction of combustible fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] introduction

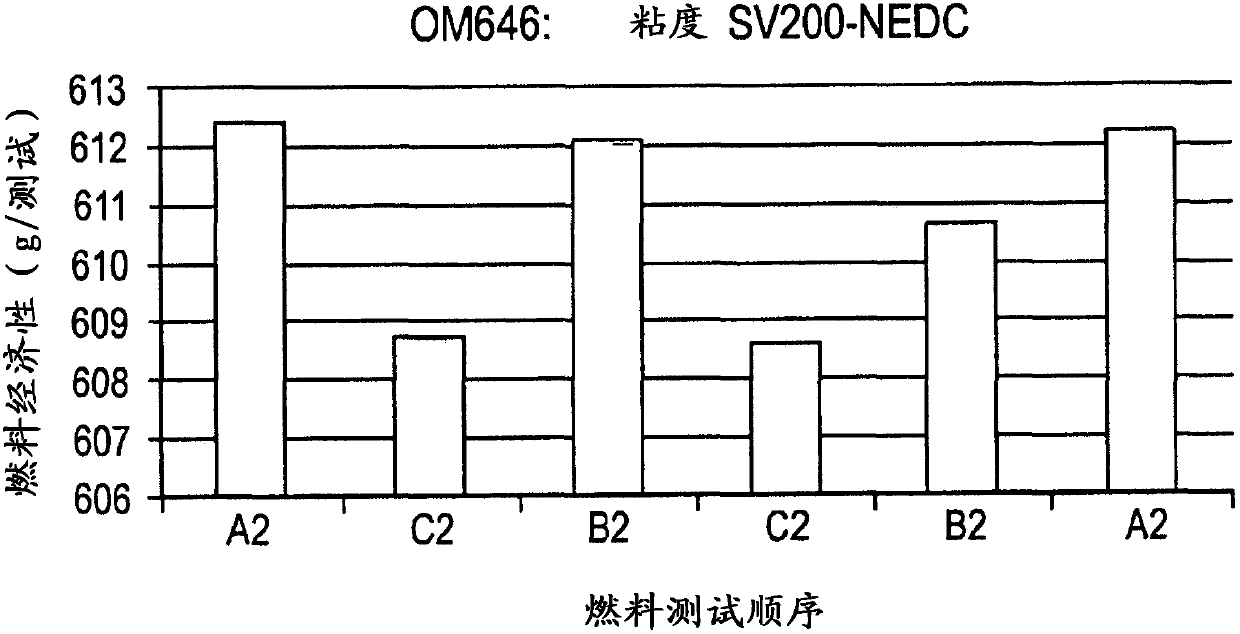

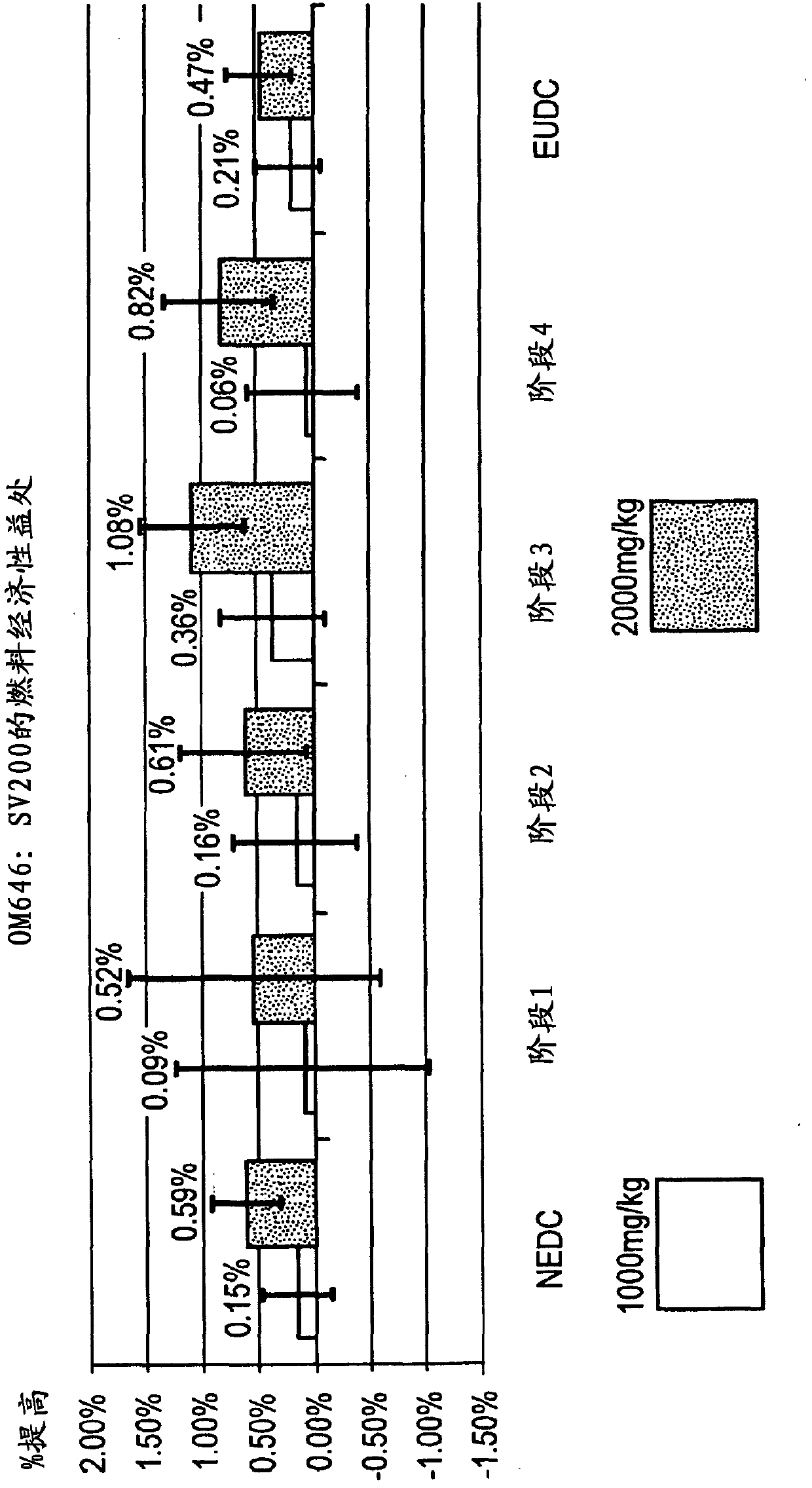

[0110] In these examples, the results of a bench engine testing program used to evaluate the effect of fuel viscosity on diesel fuel economy are reported. A standard diesel was compared to the same diesel fuel containing different concentrations of viscosity enhancing components. A VI improver, specifically ShellVis 200 ("SV200") was used as the viscosity enhancing component.

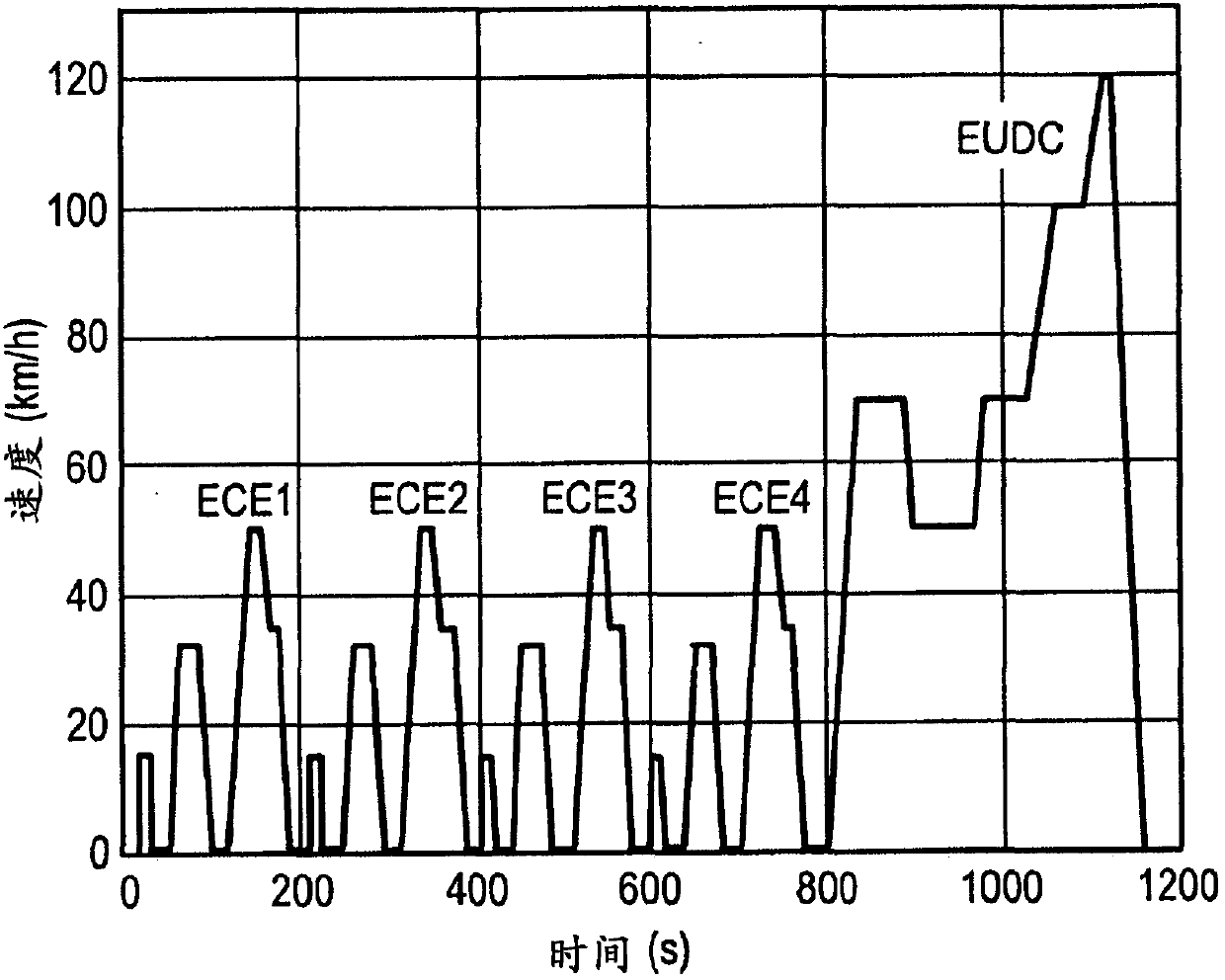

[0111] 1, Test platform and test cycle

[0112] To assess the potential impact of fuel viscosity on diesel fuel economy, a Mercedes Benz 2.21 diesel test bench engine (OM646.963L - "OM646 engine") was used for the study. The OM646 engine is a common rail diesel engine installed on the PAE test bench 007. The relevant technical information / data of the OM646 test engine used is shown in Table 1.

[0113] Table 1

[0114] motor vehicle

C220CDI, E220, construction period CDI2004-2007

cylinder

4DOHC

Displacement

2148cm 3

the power

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com