Space vector modulation method for three-level output based on three-level voltage source inverter

A technology of voltage source inverter and space vector modulation, which is applied in the field of multi-level conversion, can solve the problems of complex and cumbersome modulation strategies, complex structures, and unbalanced midpoint potentials, and achieve simplified modulation strategies, simplified topology structures, and reduced The effect of the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

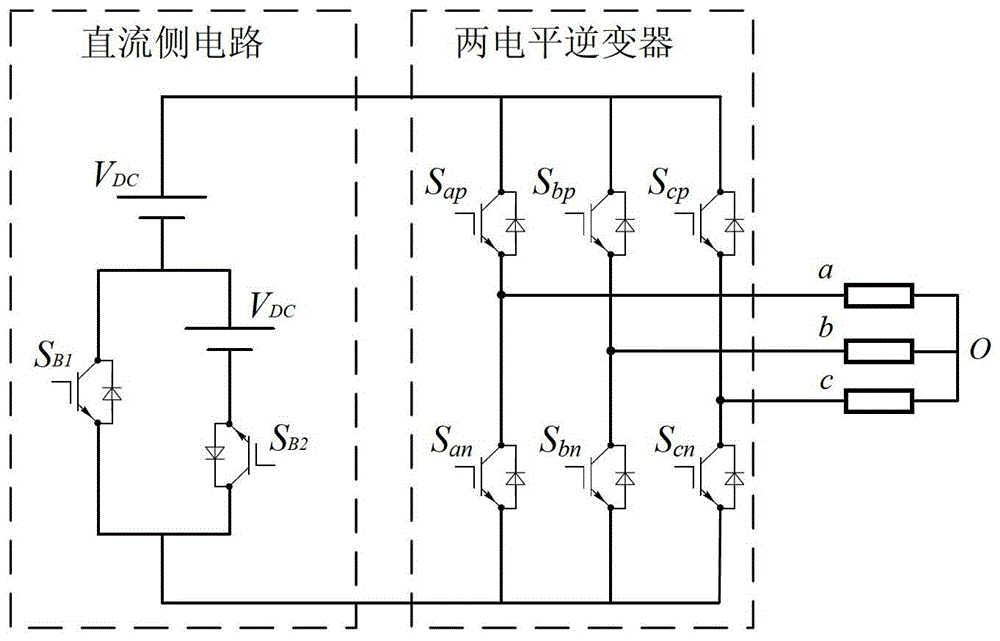

[0021] Specific implementation mode one: see figure 1 This embodiment will be described. The new three-level voltage source inverter described in this embodiment is composed of a DC side circuit and an inverter side circuit, wherein the DC side circuit is used to output DC power to the inverter side circuit, and the inverter side circuit consists of two A level inverter circuit, the two-level inverter circuit converts the input DC signal into a three-level signal for output.

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and the novel three-level voltage source inverter described in Embodiment 1 is that the two-level inverter circuit consists of six IGBT switches S ap , S bp , S cp , S an , S bn and S cn composition, the six IGBT switches in the S xn and S xp form a bridge arm, where S xn is the lower bridge arm, S xp is the upper bridge arm, x∈{a,b,c}; the three bridge arms are connected in parallel on the DC output side of the DC side circuit, and the connection point between the upper bridge arm and the lower bridge arm of each bridge arm is a two-level inverter An inverted level output of the circuit.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and the novel three-level voltage source inverter described in Embodiment 1 or 2 is that the DC side circuit consists of two DC sources and two IGBT switches S B1 , S B2 Composed of one DC power supply and one IGBT switch in series, then connected in parallel with another IGBT switch, and then connected in series with another DC power supply.

[0024] In this embodiment, the voltage amplitudes output by the two DC power supplies are both V DC .

[0025] In the novel three-level voltage source inverter of the present invention, the two IGBT switches S located in the DC side circuit B1 , S B2 The switching state of the always remains reversed.

[0026] In the novel three-level voltage source inverter of the present invention, the six IGBT switches S located in the two-level inverter circuit ap , S bp , S cp , S an , S bn and S cn , the two IGBT switch tubes S located in the same bridge arm xp and S xn The sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com