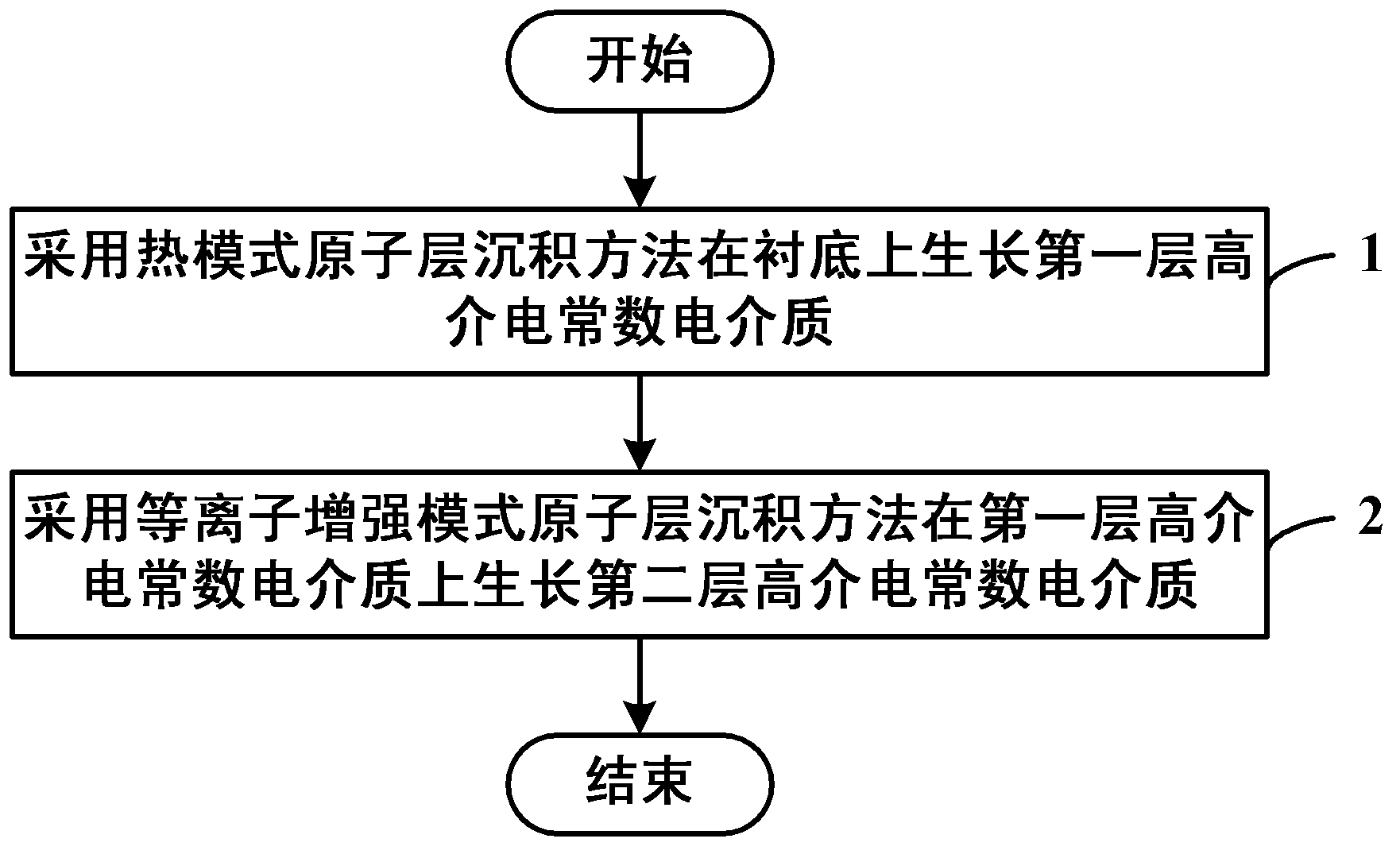

Method for growing high-dielectric constant dielectric lamination

A high dielectric constant, dielectric technology, used in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., to avoid electrical performance degradation, avoid ion damage and interface oxidation, and accurately control the film thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preferred embodiment of the present invention applied to a MOS process with a micron-level gate length will be described in detail below with reference to the accompanying drawings.

[0042] Step 1) Clean the substrate:

[0043] Rinse the GaAs substrate with MOS-grade acetone for 5 minutes, and apply ultrasound in a water bath with a power of 15W;

[0044] Rinse with MOS-grade ethanol for 5 minutes, and then apply ultrasound with a power of 15W in a water bath;

[0045] Rinse with deionized water for 3 minutes and blow dry with high-purity nitrogen;

[0046] Soak the GaAs substrate with hydrochloric acid and deionized water with a volume ratio of 1:10 for 1 minute;

[0047] Soak in MOS-grade ammonia water for 5 minutes;

[0048] Rinse with deionized water for 3 minutes and blow dry with high-purity nitrogen.

[0049] like figure 2 shown.

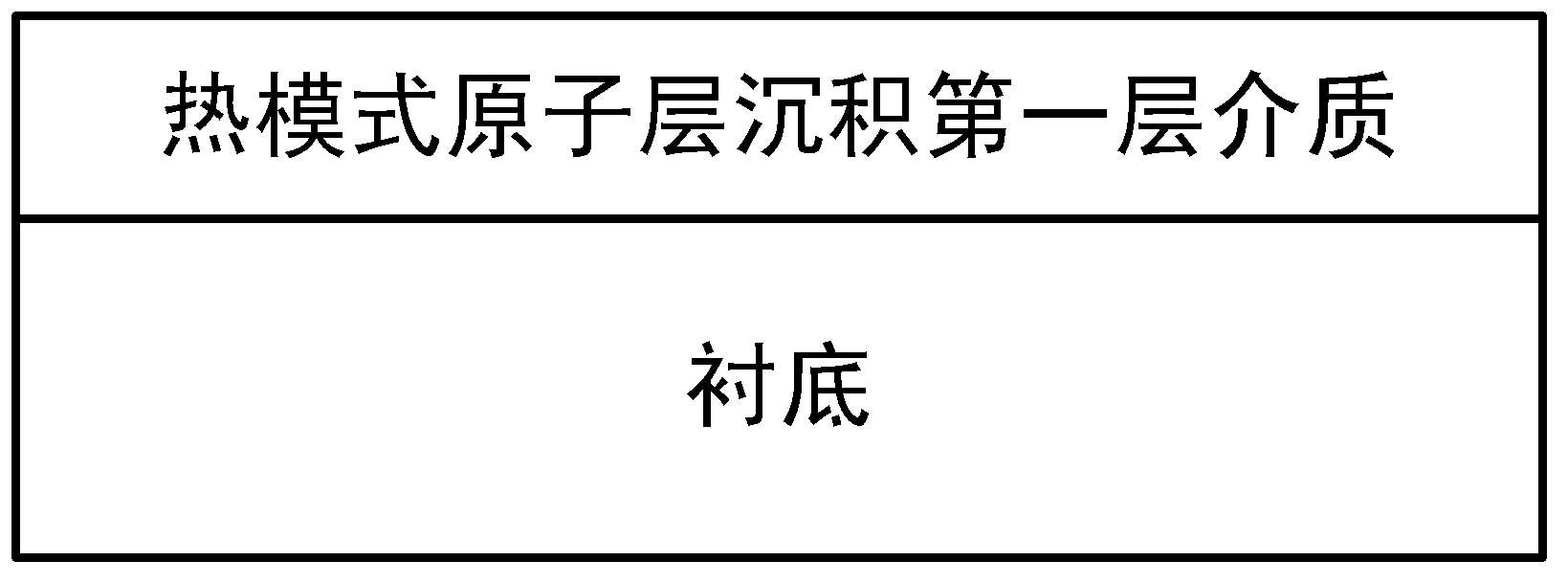

[0050] Step 2) Thermal Mode Atomic Layer Deposition of Aluminum Oxide:

[0051] The GaAs substrate cleaned in step 1) is p...

Embodiment 2

[0072] An embodiment of the present invention applied to a MOS process with a micron-scale gate length will be described in detail below with reference to the accompanying drawings.

[0073] Step 1) Clean the substrate:

[0074] Rinse the GaAs substrate with MOS-grade acetone for 5 minutes, and apply ultrasound in a water bath with a power of 15W;

[0075] Rinse with MOS-grade ethanol for 5 minutes, and then apply ultrasound with a power of 15W in a water bath;

[0076] Rinse with deionized water for 3 minutes and blow dry with high-purity nitrogen;

[0077] Soak the GaAs substrate with hydrochloric acid and deionized water with a volume ratio of 1:10 for 1 minute;

[0078] Soak in MOS-grade ammonia water for 5 minutes;

[0079] Rinse with deionized water for 3 minutes and blow dry with high-purity nitrogen.

[0080] like figure 2 shown.

[0081] Step 2) Thermal Mode ALD Oxide:

[0082] Here thermal mode atomic layer deposition of 0A oxide was carried out directly to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com