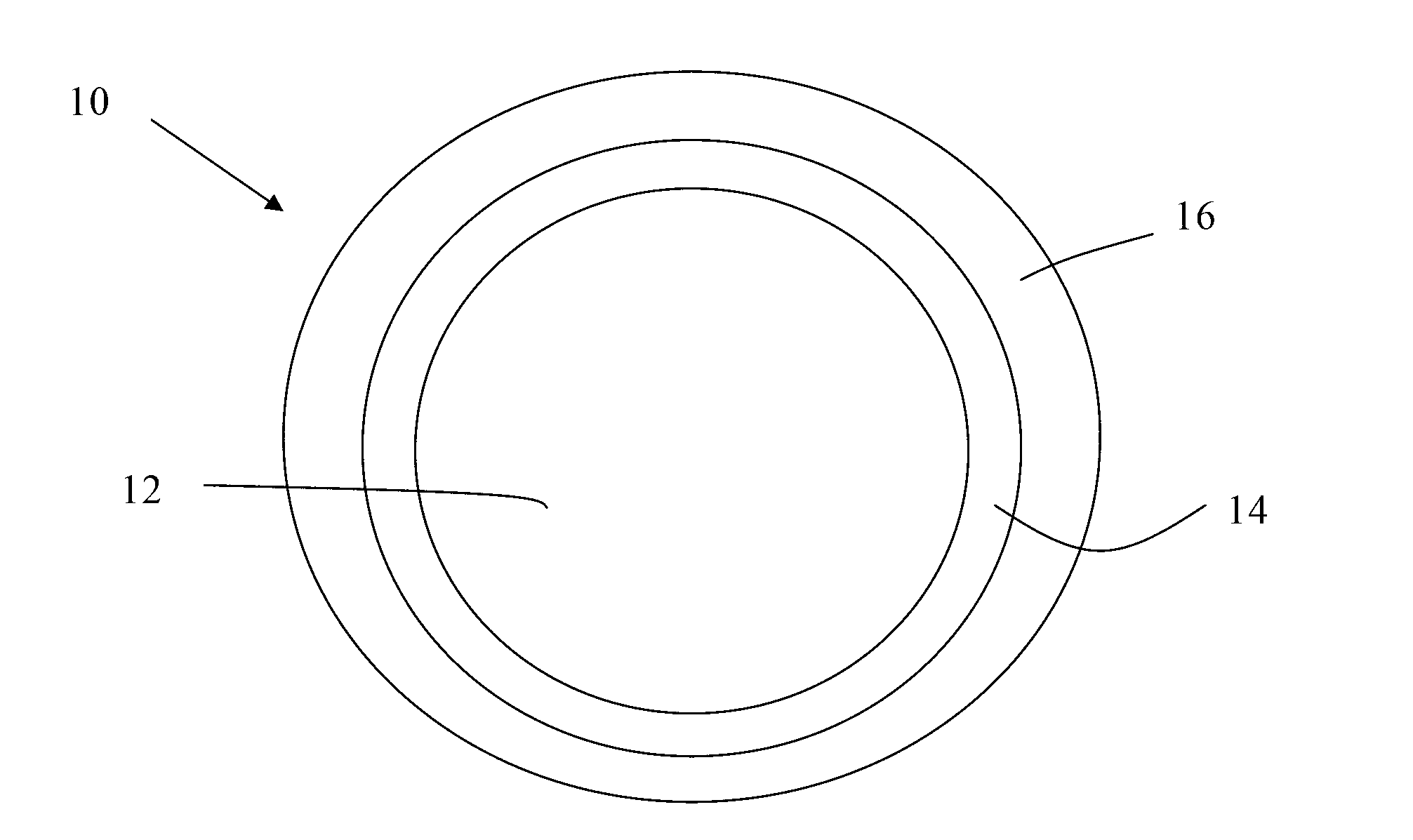

Silicon dioxide nano magnetic microsphere and preparation method thereof

A technology of silica and nano-magnetism, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, circuits, etc., can solve the problems of small specific surface area, small pore size, and uneven distribution of magnetic composite microspheres, so as to improve the binding efficiency , strong magnetism and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

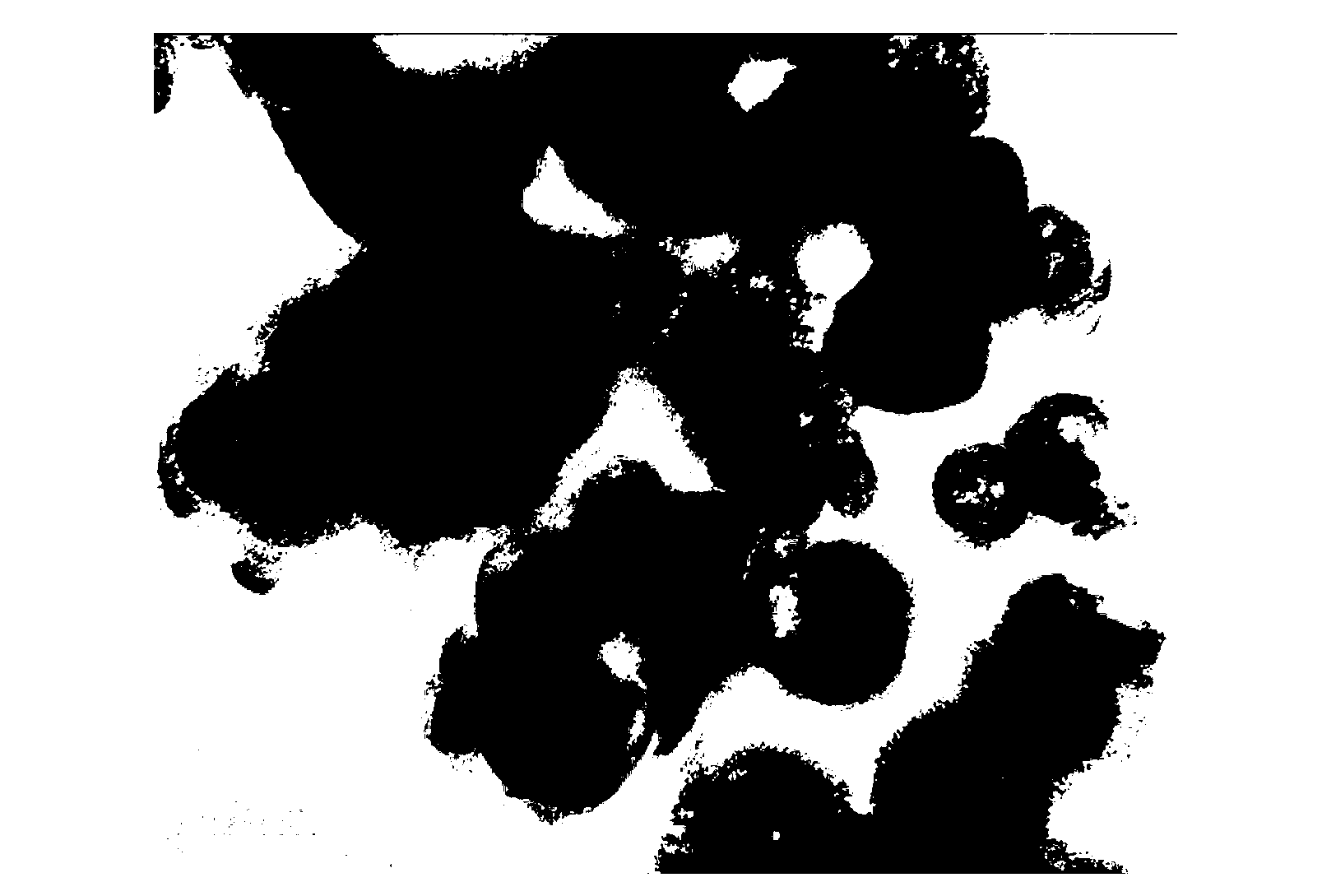

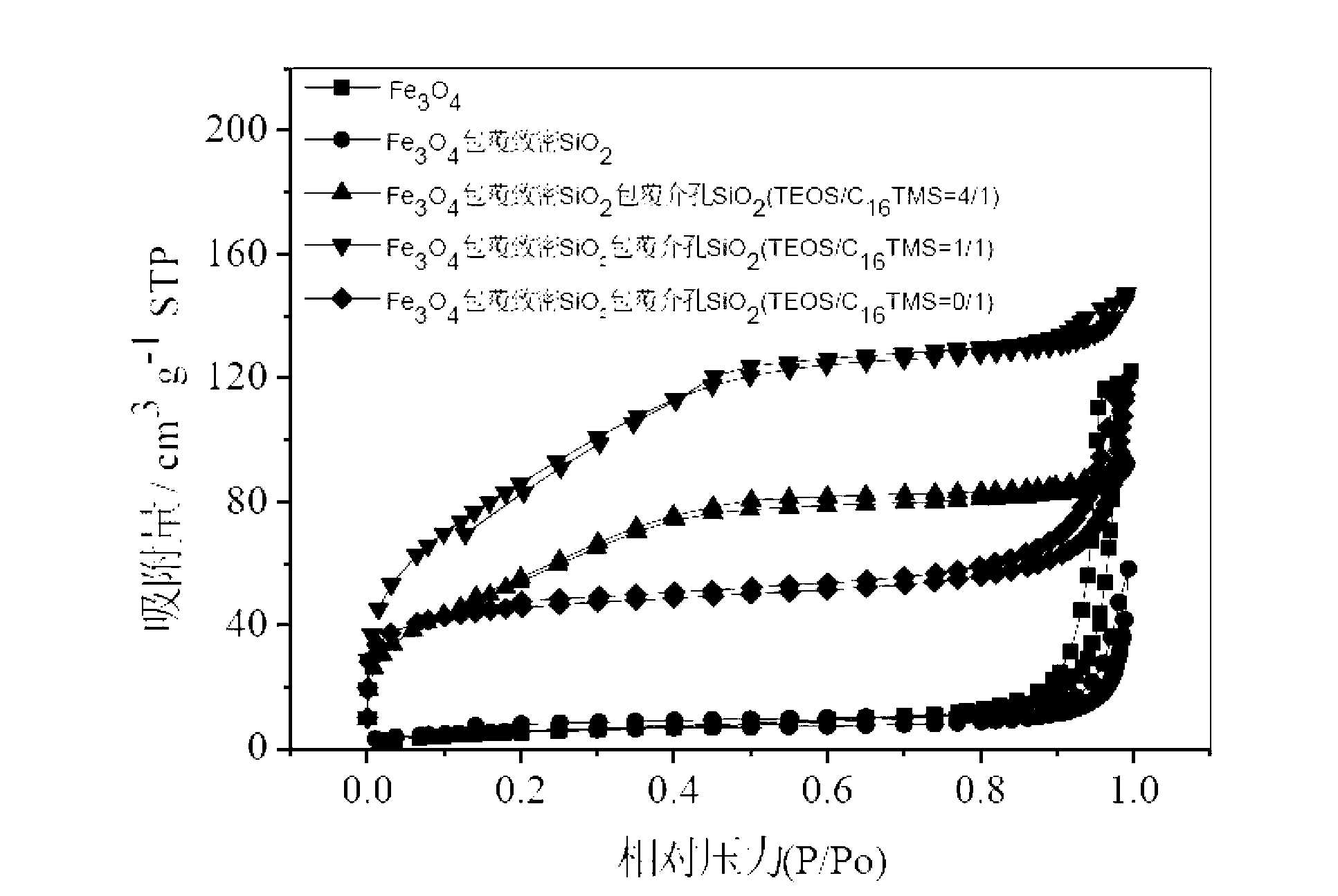

[0027] Fe prepared by hydrothermal synthesis 3 o 4 Nanospheres 0.5g, sonicated in 250mL 0.1M HCl for 10min, magnetically separated, washed 3 times with deionized water, then uniformly dispersed in 400mL ethanol and 100mL water mixed solvent, added concentrated ammonia 6mL to adjust the pH to 11, then added TEOS (tetraethyl orthosilicate) 6mL, stirred at room temperature for 6h, magnetically separated, washed repeatedly with ethanol and water, dispersed again in 170mL ethanol and 30mL water, added ammonia water 8mL, added dropwise the mesoporous silica precursor (volume ratio 1:4 mixture of hexadecyltrimethoxysilane and ethyl orthosilicate), add 6mL and stir for 12h. Magnetic separation, washing with deionized water and ethanol several times, and vacuum drying at 60°C. Burn the obtained powder at 550° C. to remove the alkyl group, and obtain silica nano-magnetic microspheres with mesoporous structure. The obtained silica nano-magnetic microspheres have a specific surface of ...

Embodiment 2

[0029] Fe prepared by hydrothermal synthesis 3 o 4 Ultrasonicate 0.5g of nanospheres in 250mL of 0.1M HCl for 10min, magnetically separate, wash with deionized water for 3 times, then uniformly disperse in a mixed solvent of 400mL of ethanol and 100mL of water, add 6mL of concentrated ammonia water to adjust the pH to 11, then add 6mL of TEOS , stirred at room temperature for 6 hours, magnetically separated, washed repeatedly with ethanol and water, dispersed again in 170mL of ethanol and 30mL of water, added 8mL of ammonia water, and added dropwise silica precursor hexadecyltrimethoxysilane and ethyl orthosilicate A total of 6 mL of the ester mixture (volume ratio 1:1) was stirred for 16 h. Magnetic separation, washing with deionized water and ethanol several times, and vacuum drying at 60°C. Burn the obtained powder at 550° C. to remove the alkyl group, and obtain silica nano-magnetic microspheres with mesoporous structure. The obtained silica nano-magnetic microspheres h...

Embodiment 3

[0031] Fe prepared by hydrothermal synthesis 3 o 4 Ultrasonicate 0.5g of nanospheres in 250mL of 0.1M HCl for 10min, magnetically separate, wash with deionized water for 3 times, then uniformly disperse in a mixed solvent of 400mL of ethanol and 100mL of water, add 6mL of concentrated ammonia water to adjust the pH to 11, then add 6mL of TEOS , stirred at room temperature for 6 h, magnetically separated, washed repeatedly with ethanol and water, dispersed again in 170 mL of ethanol and 30 mL of water, added 8 mL of ammonia water, added dropwise 6 mL of silica precursor hexadecyltrimethoxysilane, and stirred for 16 h. Magnetic separation, washing with deionized water and ethanol several times, and vacuum drying at 60°C. Burn the obtained powder at 550° C. to remove the alkyl group, and obtain silica nano-magnetic microspheres with mesoporous structure. The specific surface of the obtained silica nano-magnetic microspheres tested on the micrometrics ASAP2020 specific surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com