Method for screening plasticizer

A plasticizer and screening technology, which is applied in the field of rapid screening of plasticizers, can solve problems such as failure to meet market demand, carcinogenic reproductive system, long R&D cycle, etc., to improve operational efficiency, shorten time, and test costs Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment one certain brand 46 degree liquor

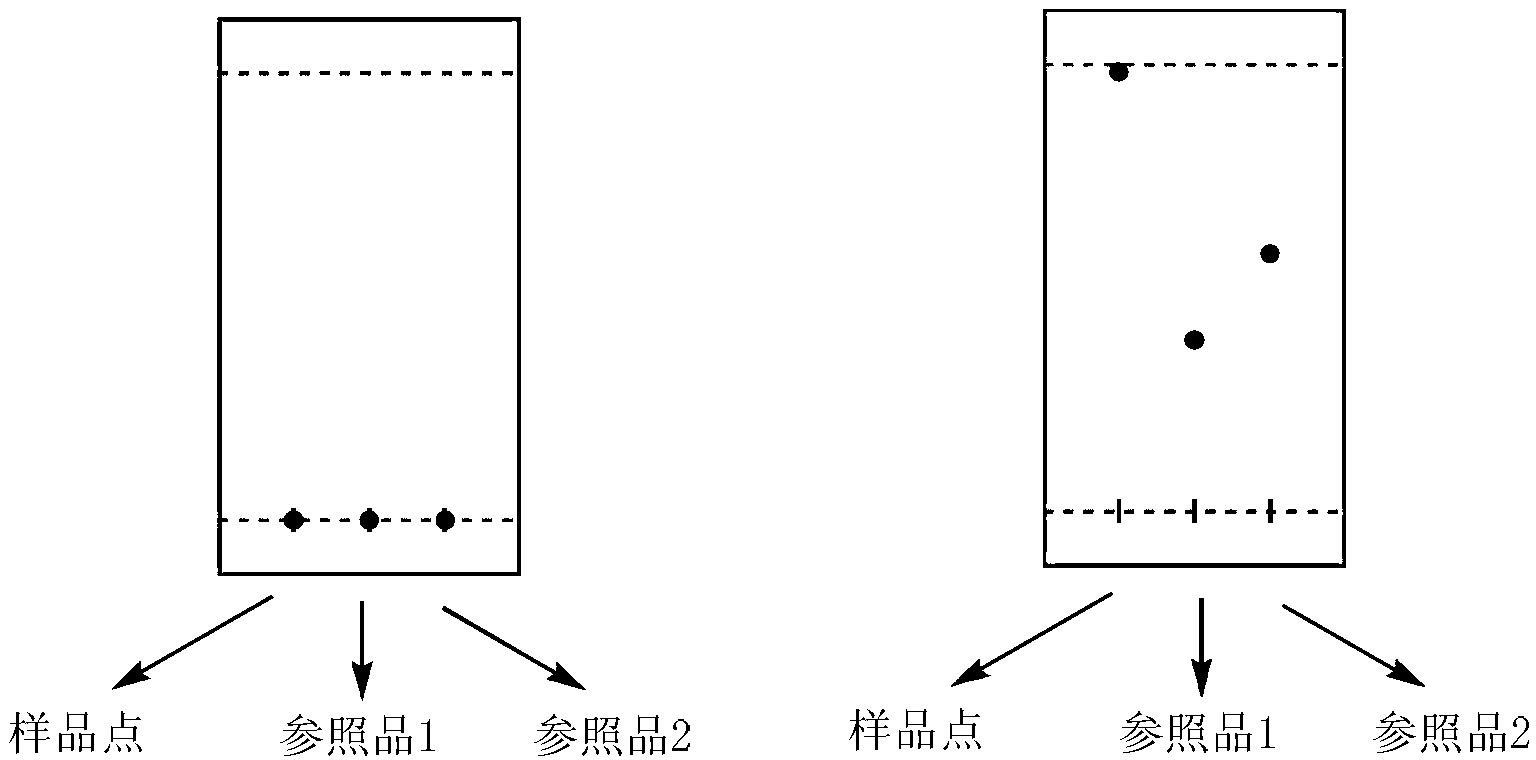

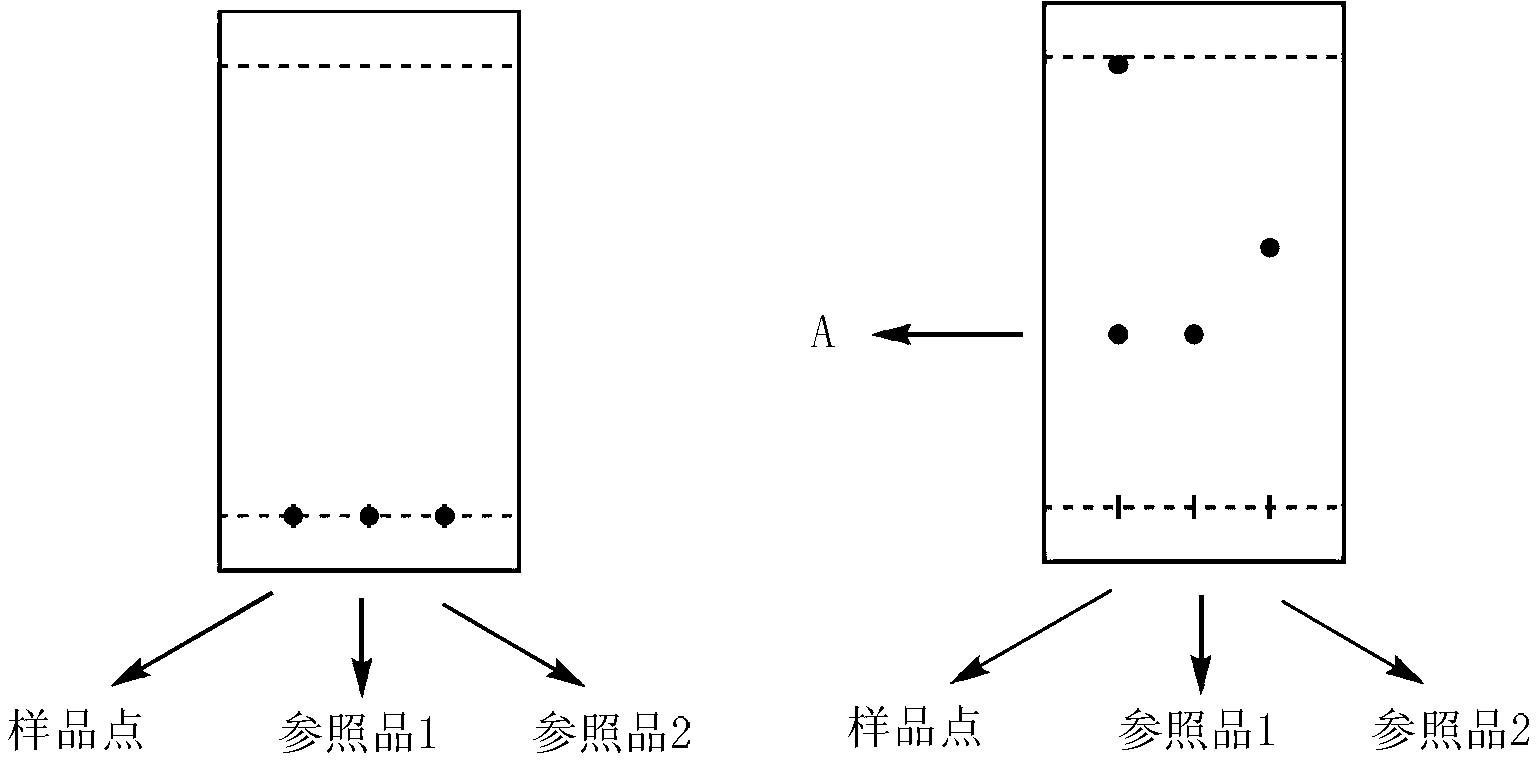

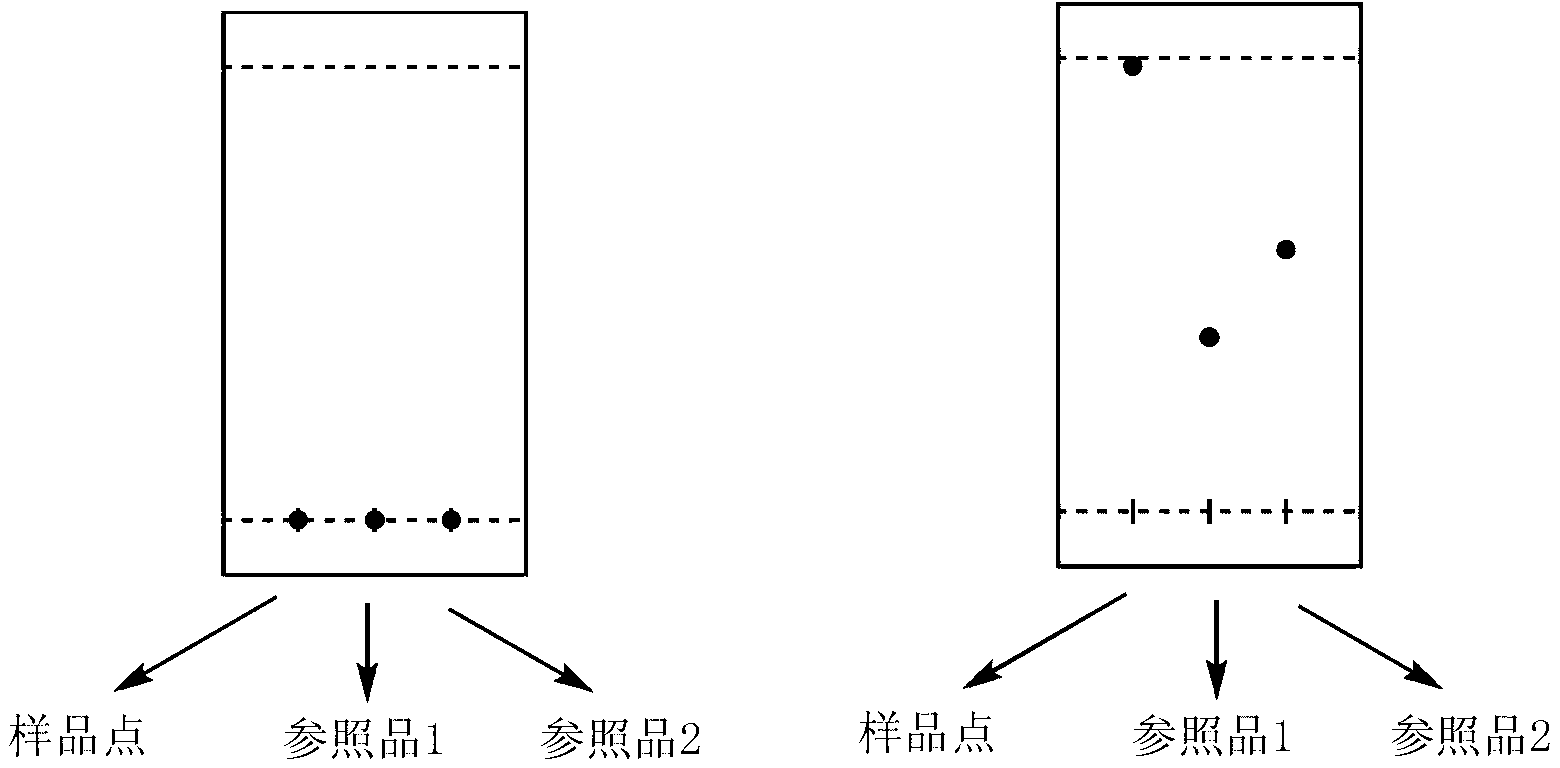

[0061] Use 2.5mL methanol and 2.5mL water to activate the solid-phase extraction column (filler is PLS) in sequence, take the liquor directly in four times, and put 2.5mL on the column each time. After loading the sample, wash the column with 2.5 mL of acetone solution, and discard all effluent. Use 2.5mL1 / 1 ethanol / ethyl acetate to elute the plasticizer in the solid phase extraction column, and collect the eluted liquid. The flow rate of the liquid in the above steps is one drop every 2-3 seconds. The eluted liquid is stratified, suck the lower layer, and pay attention to minimize the loss of the upper layer. Then dry the upper layer liquid using a sample concentrator at a temperature of 60° C. for 10 to 15 minutes. Take 20 microliters of ethyl acetate to redissolve the dried sample, making sure to dissolve all the substances on the wall. Take 1 microliter of the reconstituted sample and spot the plate, each take 1 mic...

Embodiment 2

[0062] Embodiment two certain brand 38 degree liquor

[0063] Use 2.5mL methanol and 2.5mL water to activate the solid-phase extraction column (filler is PLS) in sequence, take the liquor directly in four times, and put 2.5mL on the column each time. After loading the sample, wash the column with 2.5 mL of 20% methanol in water, and discard all the effluent. Use 3.5 mL of dichloromethane to elute the plasticizer in the solid-phase extraction column, and collect the eluted liquid. The flow rate of the liquid in the above steps is one drop every 2-3 seconds. The eluted liquid is stratified, suck the lower layer, and pay attention to minimize the loss of the upper layer. Then the upper liquid was blown dry using a sample concentrator at a temperature of 60° C. for 5 minutes. Take 20 microliters of ethyl acetate to redissolve the dried sample, making sure to dissolve all the substances on the wall. Take 1 microliter of the reconstituted sample and spot the plate, each take 1 mi...

Embodiment 3

[0064] Embodiment three certain brand 52 degree liquor

[0065] Use 2.5mL methanol and 2.5mL water to activate the solid-phase extraction column (filler is PSA) in sequence, and take samples directly in four times, each time 2.5mL is loaded on the column. After loading the sample, wash the column with 2.5 mL of 5% ethanol aqueous solution, and discard all the effluent. Use 2.5mL ethyl acetate to elute the plasticizer in the solid-phase extraction column, and collect the eluted liquid. The flow rate of the liquid in the above steps is one drop every 2-3 seconds. The eluted liquid is stratified, suck the lower layer, and pay attention to minimize the loss of the upper layer. Then dry the upper layer liquid using a sample concentrator at a temperature of 60° C. for 10 to 15 minutes. Take 20 microliters of ethyl acetate to redissolve the dried sample, making sure to dissolve all the substances on the wall. Take 1 microliter of the reconstituted sample and spot the plate, each t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com