Novel air conditioner dehumidification unit

An air-conditioning and dehumidification technology, applied in air-conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve problems such as limited application range, limited temperature drop, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

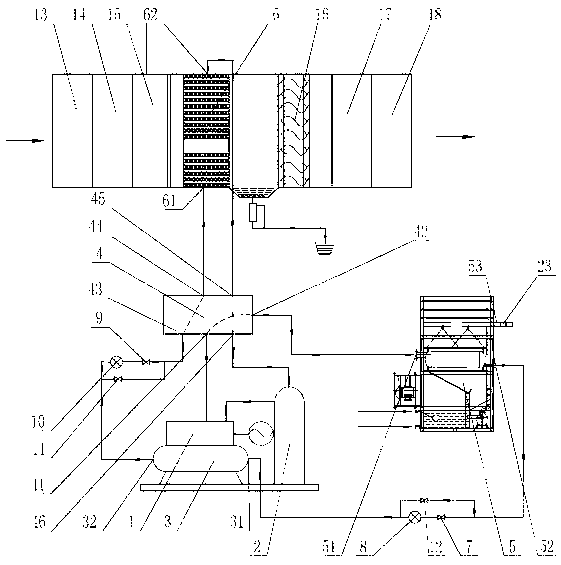

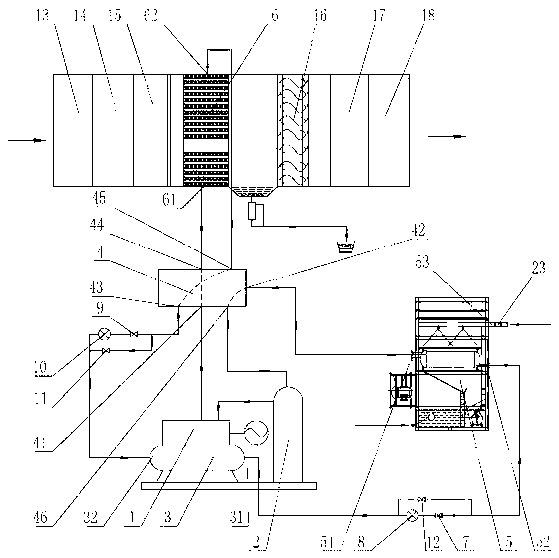

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0020] See figure 1 , the present invention includes a compressor 1, a separation tank 2 and a liquid storage tank 3, the output end of the compressor 1 is connected to the first port 41 of the first reversing valve 4, and the second port 42 of the first reversing valve 4 is connected to the dew point indirect The first port 51 of the evaporative cooling device 5, the second port 52 of the dew point indirect evaporative cooling device 5 communicates with the first port 31 of the liquid storage tank 3 through the first valve 7 and the first throttle valve 8, and the first port 31 of the liquid storage tank 3 The second port 32 communicates with the third port 43 of the first reversing valve 4 through the second valve 9 and the second throttle valve 10, and the fourth port 44 of the first reversing valve 4 is connected to the first plate-fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com