Method for improving heat radiating efficiency of LED lighting source and integrated radiator

A technology for LED lighting and heat dissipation efficiency, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of poor heat dissipation performance and low lifespan of LED lighting light sources, achieve simple structure and reduce manufacturing costs. , the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

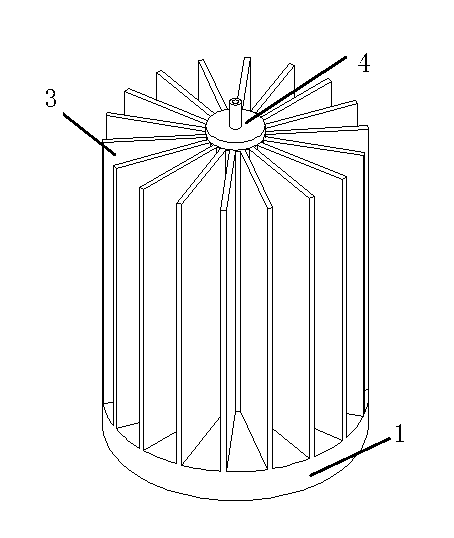

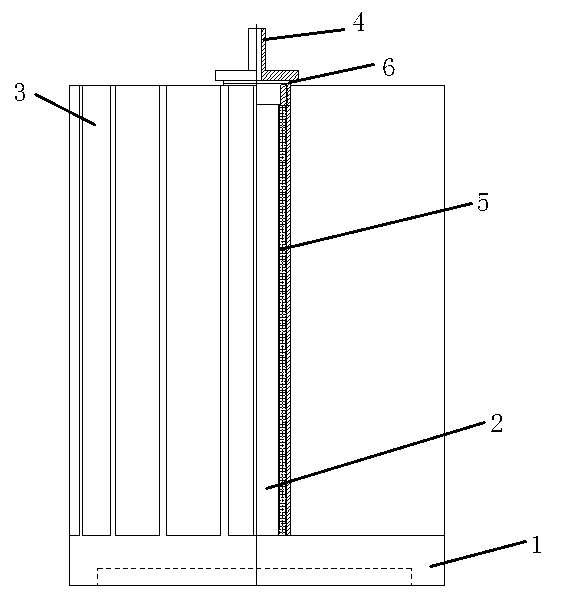

[0036] like figure 1 shown.

[0037] A method for improving the heat dissipation efficiency of LED lighting sources based on heat pipe technology. The key is to install the LED chip substrate in the substrate groove of a horizontally placed integrated heat pipe radiator, so that the heat generated by the LED light source can be transferred to the heat pipe for heat dissipation through heat conduction. The evaporation end of the cylindrical direct heat pipe 2 perpendicular to the base plate of the device makes the working medium in the cylindrical direct heat pipe 2 absorb heat to produce a liquid-vapor phase transition, and the generated steam diffuses to the entire cylindrical direct heat pipe under the action of the pressure difference inside the heat pipe The tube body, so as to exchange heat with the surrounding environment through the tube wall and the heat dissipation fins 3 on the tube wall, the steam condenses into small droplets and then adheres to the tube wall liqui...

Embodiment 2

[0039] like Figure 1-4 shown.

[0040] An integrated heat sink for LED lighting sources based on heat pipe technology, which is mainly composed of the following components:

[0041] A heat pipe radiator substrate 1, the heat pipe radiator substrate is preferably a cylinder, with a groove at the bottom, the groove shape is preferably circular, and can also be designed according to the specific size of the LED lighting source, and the overall heat conductivity is good Made of die-cast aluminum material, figure 1 The overall shape of the heat pipe radiator substrate is a cylinder, the optimum height is 12mm, the optimum diameter is 85mm, the depth of the groove at the bottom is preferably 6mm, and the diameter is 75mm. The specific size matches the LED lighting source used; the heat pipe dissipates heat The bottom surface of the groove where the device substrate 1 is in contact with the LED lighting source is preferably equipped with a thermally conductive film or thermally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com