Operating method of buffer for adjusting piston motion according to impact pressure

A working method and shock absorber technology, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems that the impact energy will not be constant and difficult to achieve, so as to prolong the life of the buffer and apply to the place broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

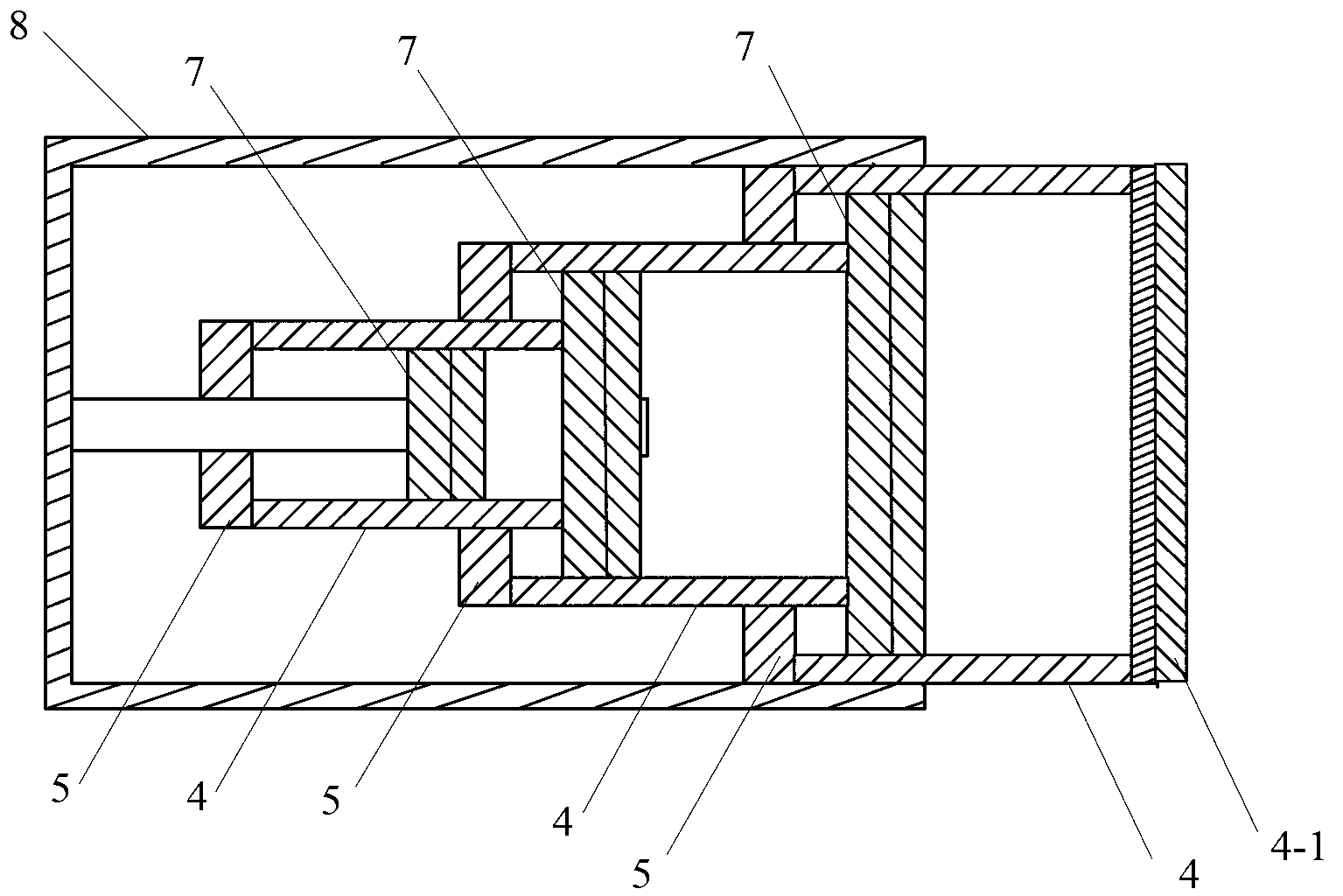

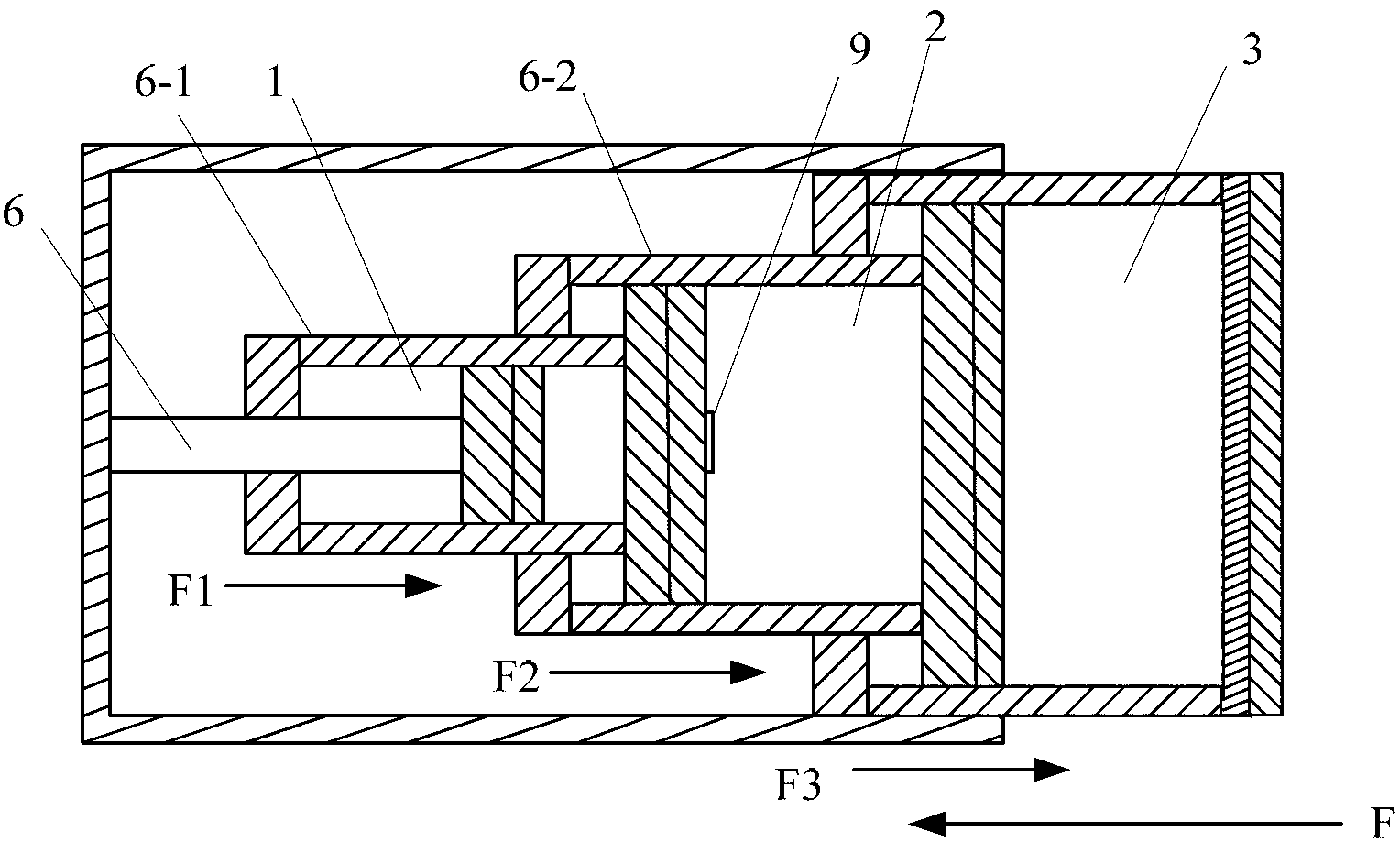

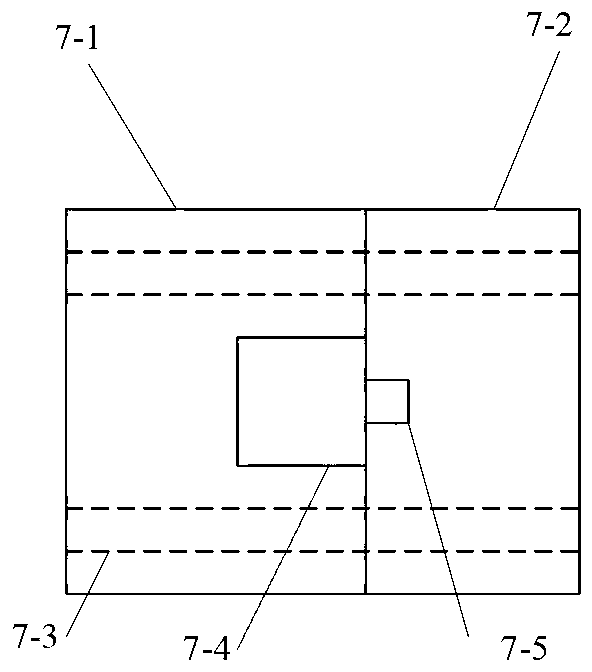

[0015] See figure 1 , figure 2 and Figure 5 , a working method of a buffer, the buffer is a three-level buffer, and the three-level buffer includes: a first-level buffer 1, an intermediate-level buffer 2 and a final-level buffer 3; the first-level buffer 1. The intermediate buffer and the final buffer 3 respectively include: a cylinder 4 that is cylindrical and filled with a buffer medium, and a cylinder cover 5 is sealed at the open end of the cylinder 4, and the cylinder cover 5 A piston rod 6 is fitted in the central through hole of the seal movable, and the right end of the piston rod 6 is provided with a piston body assembly 7, and the piston body assembly 7 is suitable for piston movement in the cylinder body 4, and is connected with the cylinder body The inner wall of 4 is movable and sealed; wherein, the cylinder body 4 of the first-stage buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com