Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Overcome technical issues that don't work together" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-automatic hydraulic molding machine for producing hollow block

ActiveCN103386707AShock mitigationExtend your lifeSpringsCeramic shaping apparatusMolding machineEngineering

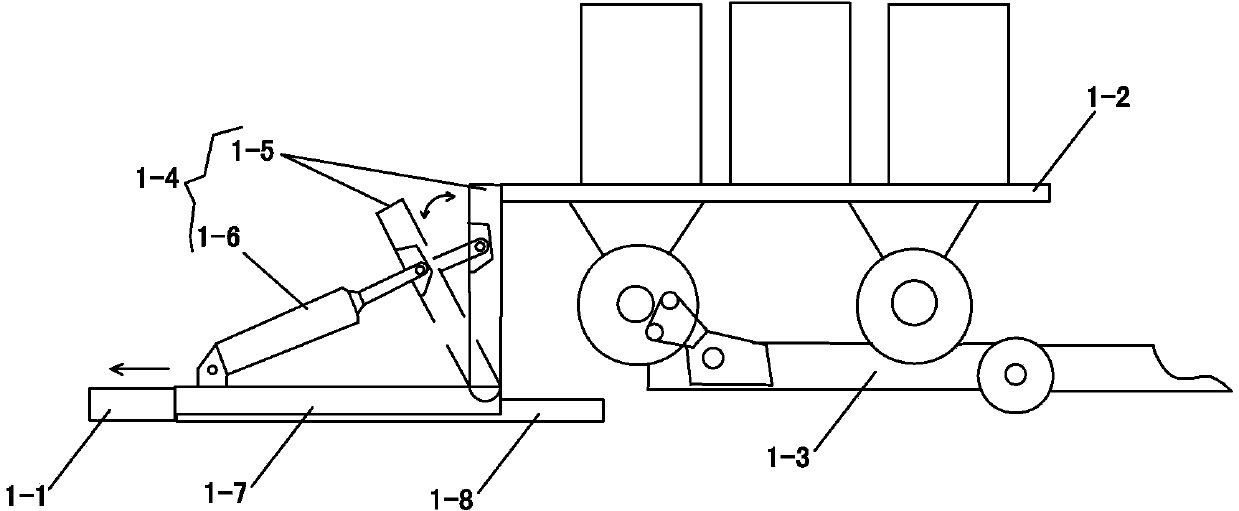

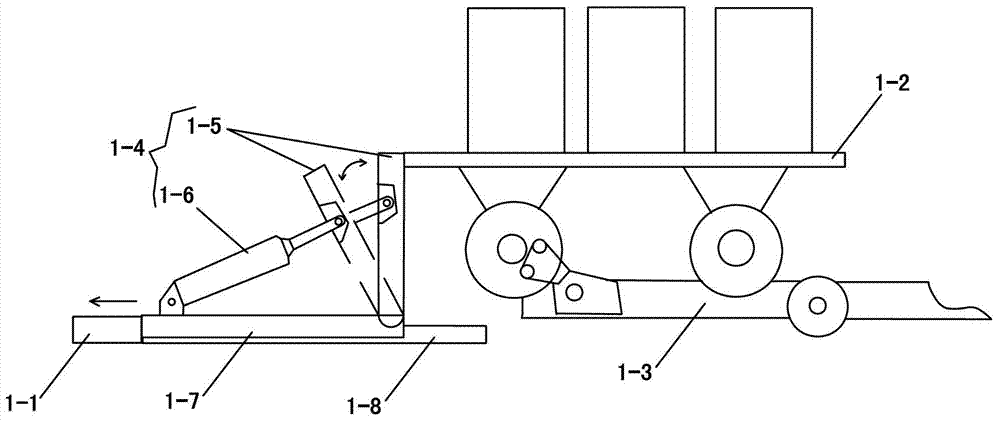

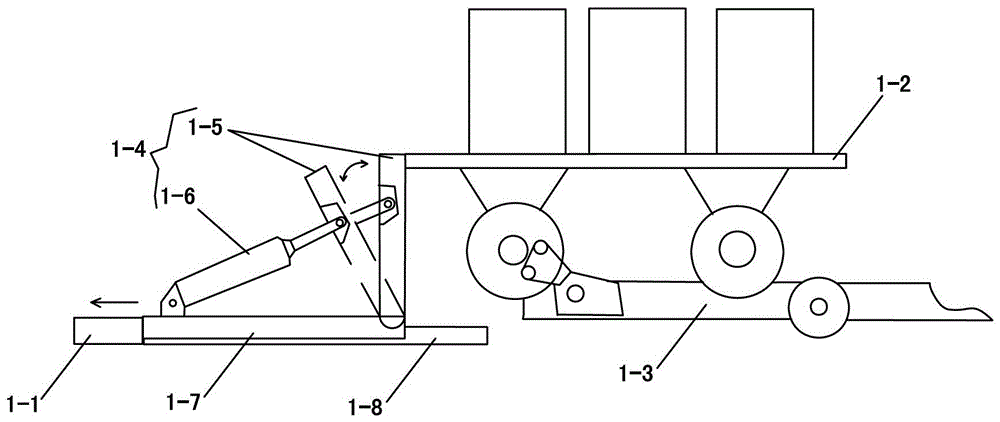

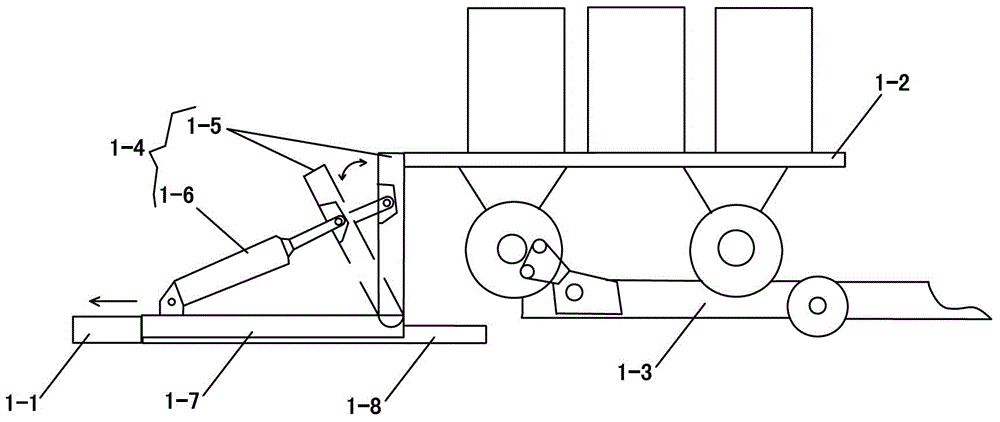

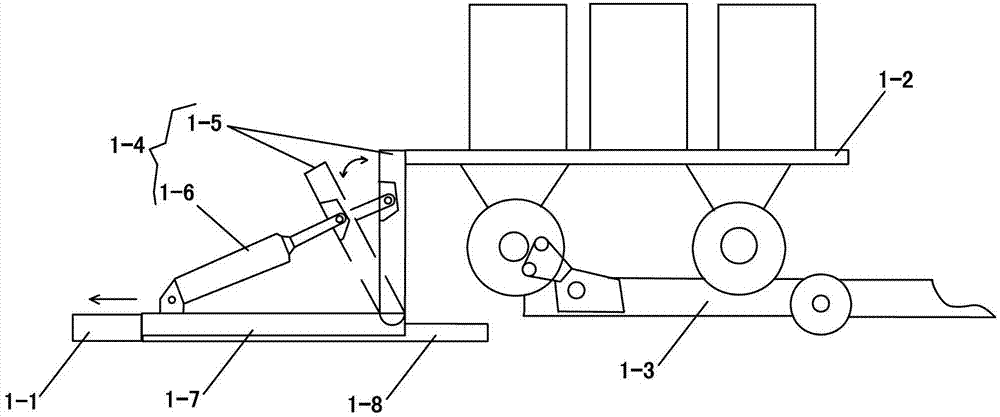

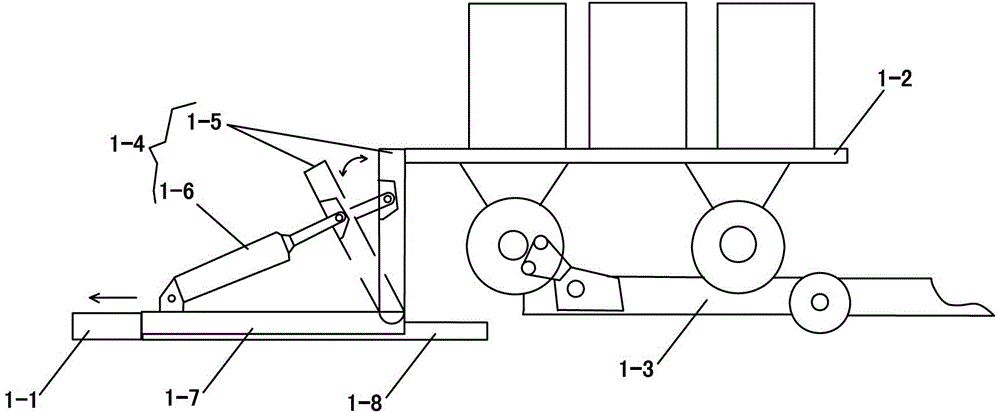

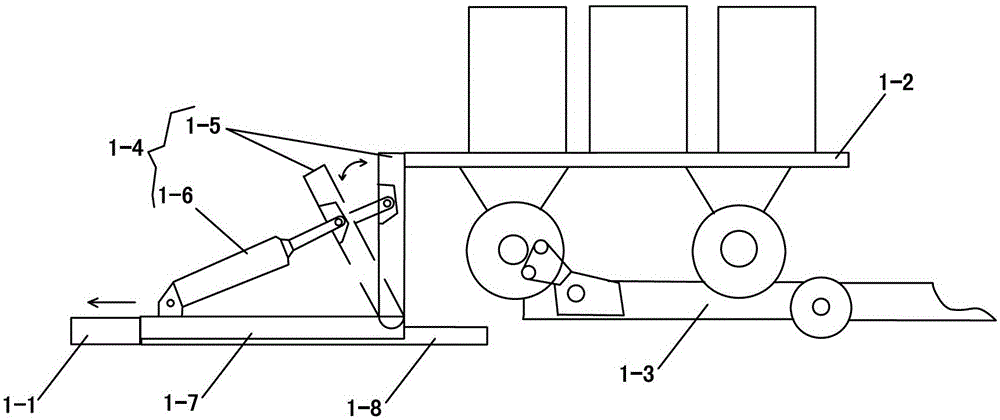

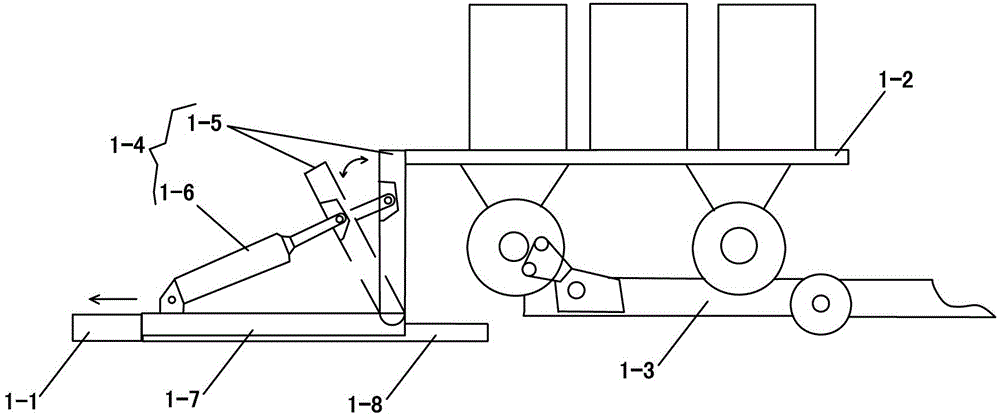

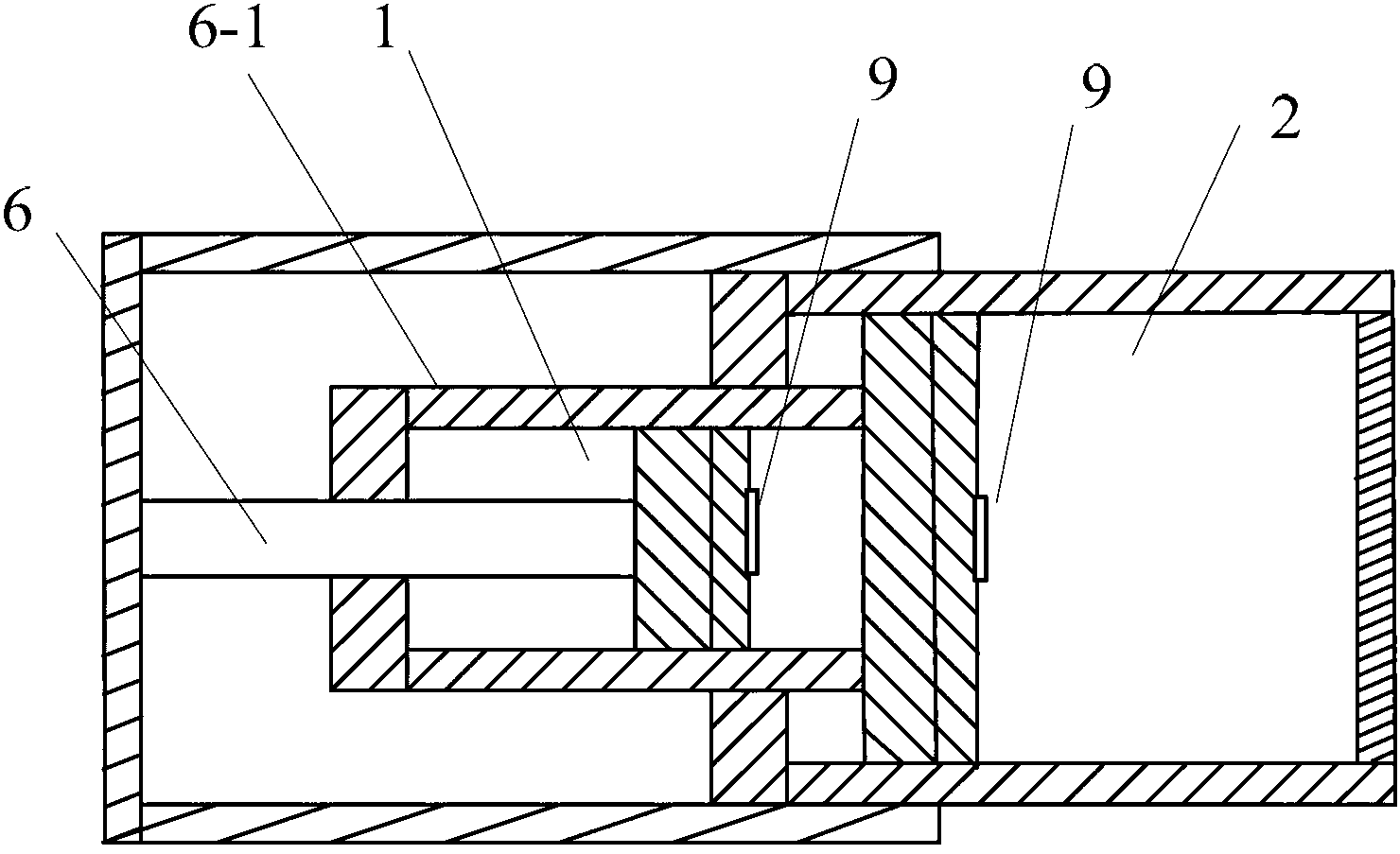

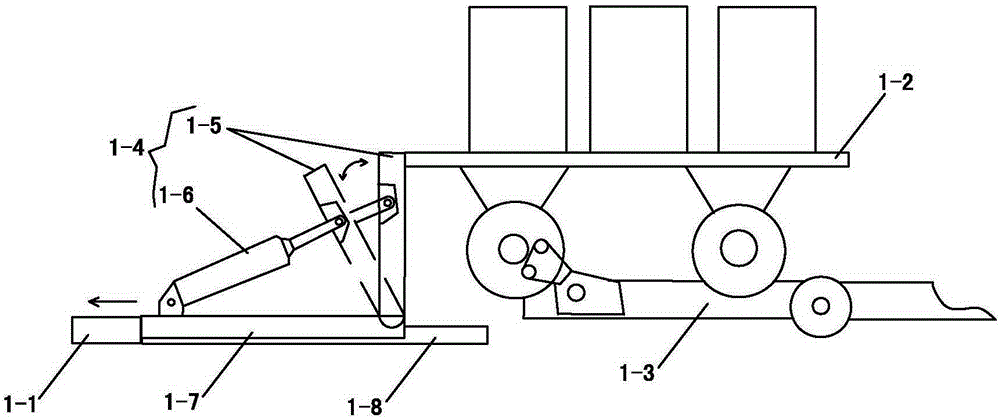

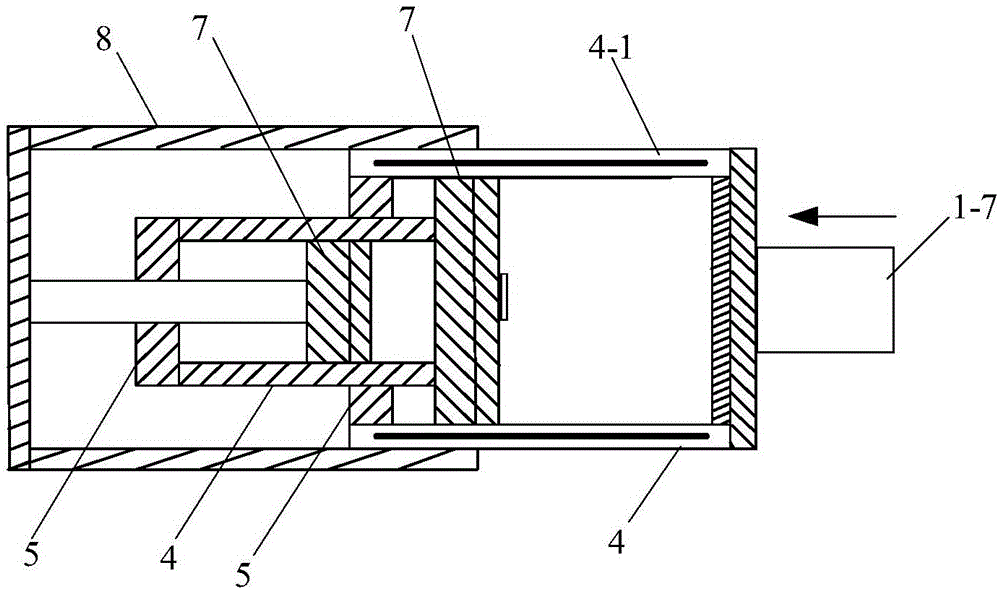

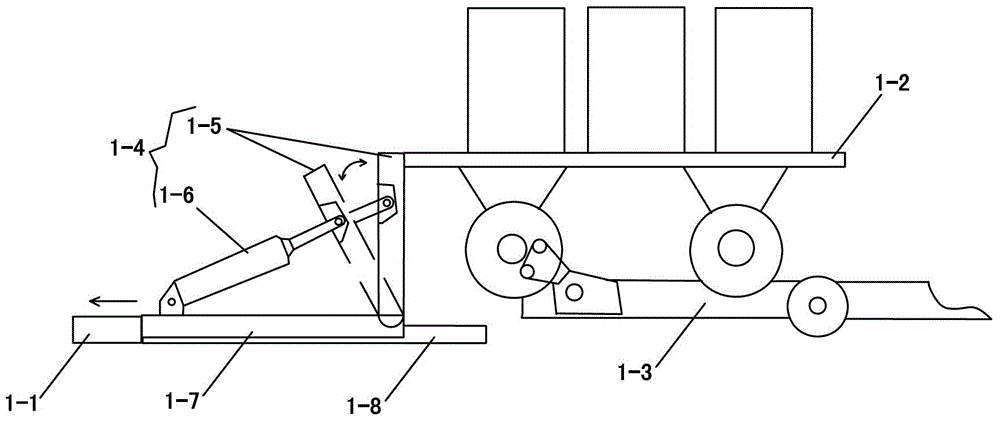

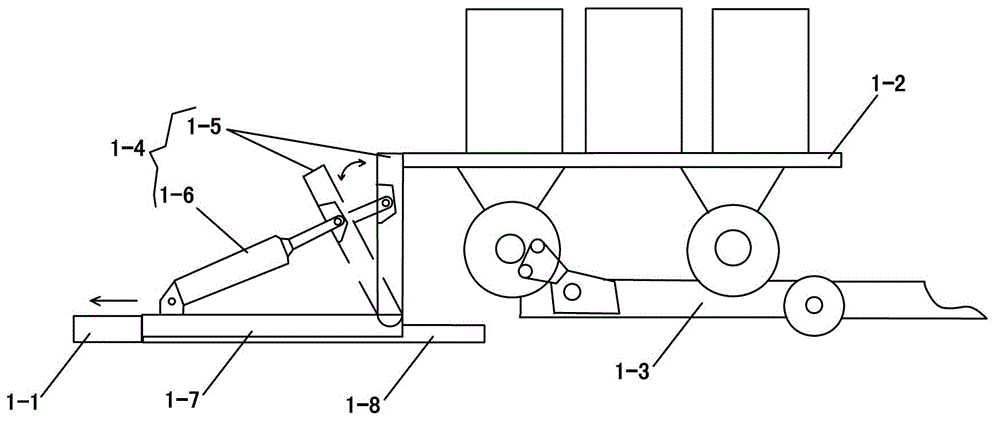

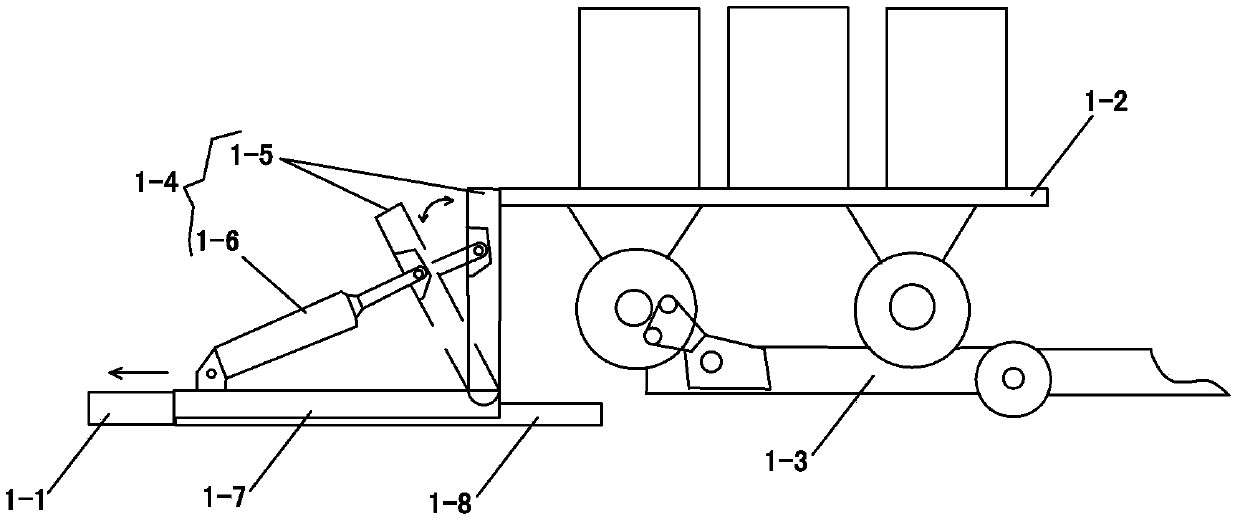

The invention relates to a full-automatic hydraulic molding machine for producing a hollow block. The full-automatic hydraulic molding machine comprises an automatic feeder for pushing a steam-curing car to a stacking area and a positioner for limiting the steam-curing car to the stacking area, wherein the positioner comprises a support arm and an air cylinder for supporting up or putting down the support arm; the positioner is fixedly arranged on the upper end face of a sliding block; the sliding block is in sliding fit with a guide rail body; a buffer device is arranged at the left end of the guide rail body and is used for buffering an impact force of the sliding block, which is generated when the steam-curing car impacts the positioner; the buffer device is also used for buffering the impact force of the sliding block when the steam-curing car impacts the supported support arm so as to relieve the pressure on the air cylinder, which is caused by the impact of the steam-curing car. According to the full-automatic hydraulic molding machine disclosed by the invention, the impact force on the air cylinder, which is caused by the steam-curing car, is buffered by the buffer device when the steam-curing car impacts the supported support arm, so that the impact force borne by the air cylinder can be effectively relieved and the service life of the air cylinder is effectively prolonged.

Owner:临沭县济才人力资源服务有限公司

Three-level buffer suitable for achieving uniform buffering at all levels

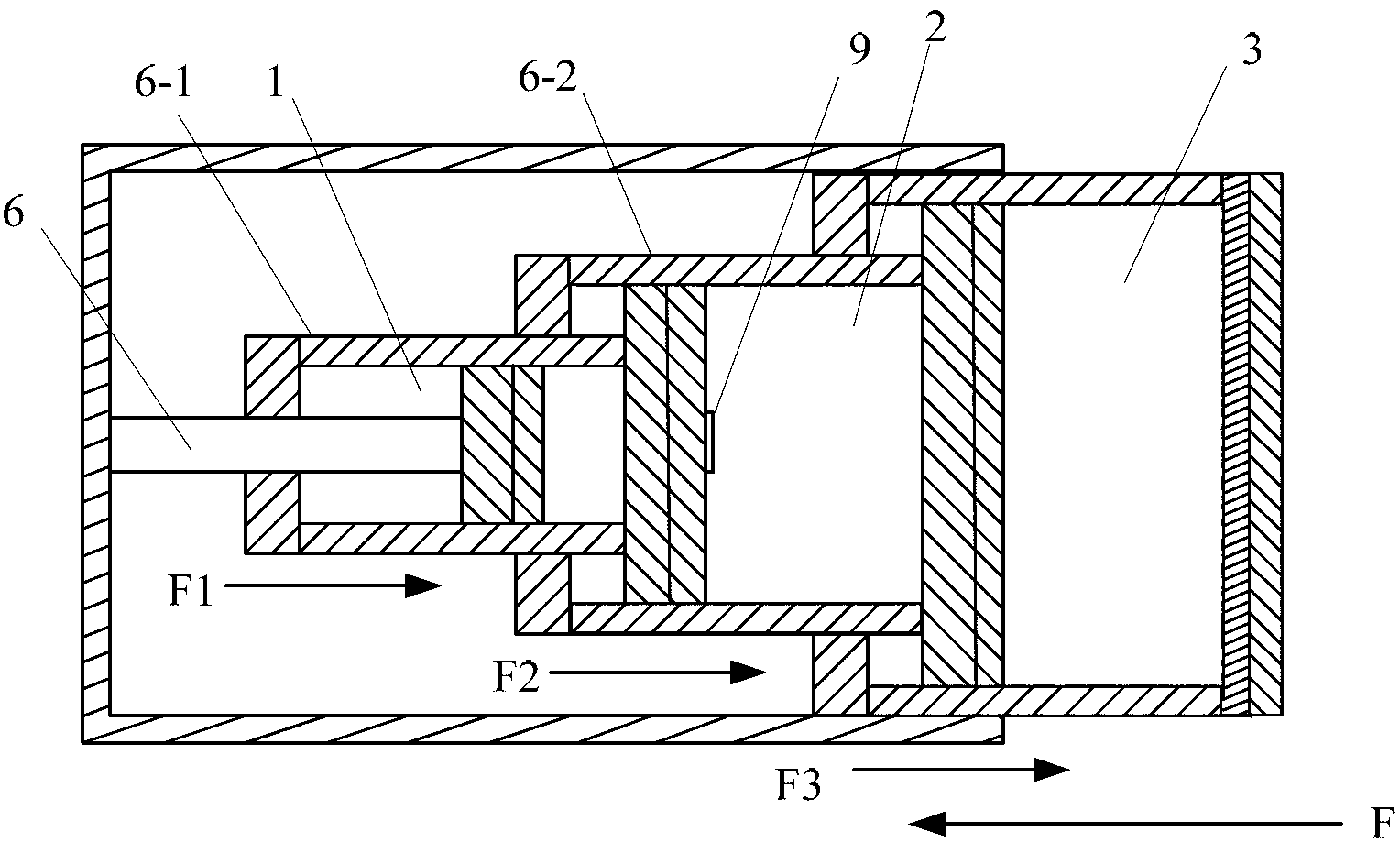

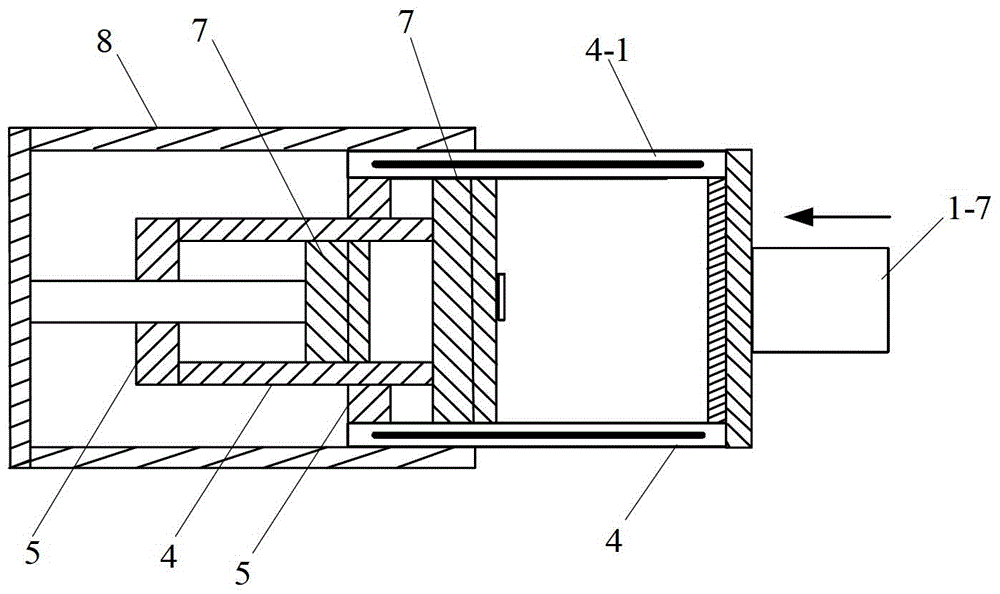

InactiveCN103352952AExtend your lifeControl movement speedSpringsLiquid based dampersThree levelCylinder block

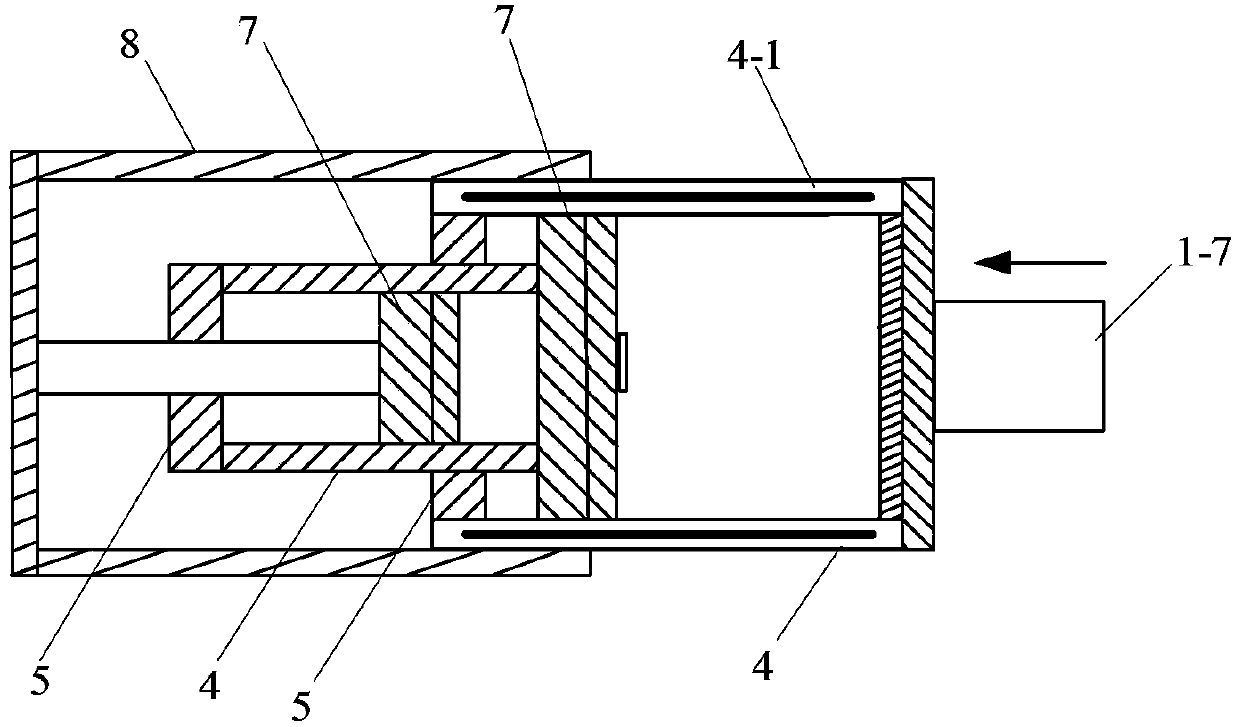

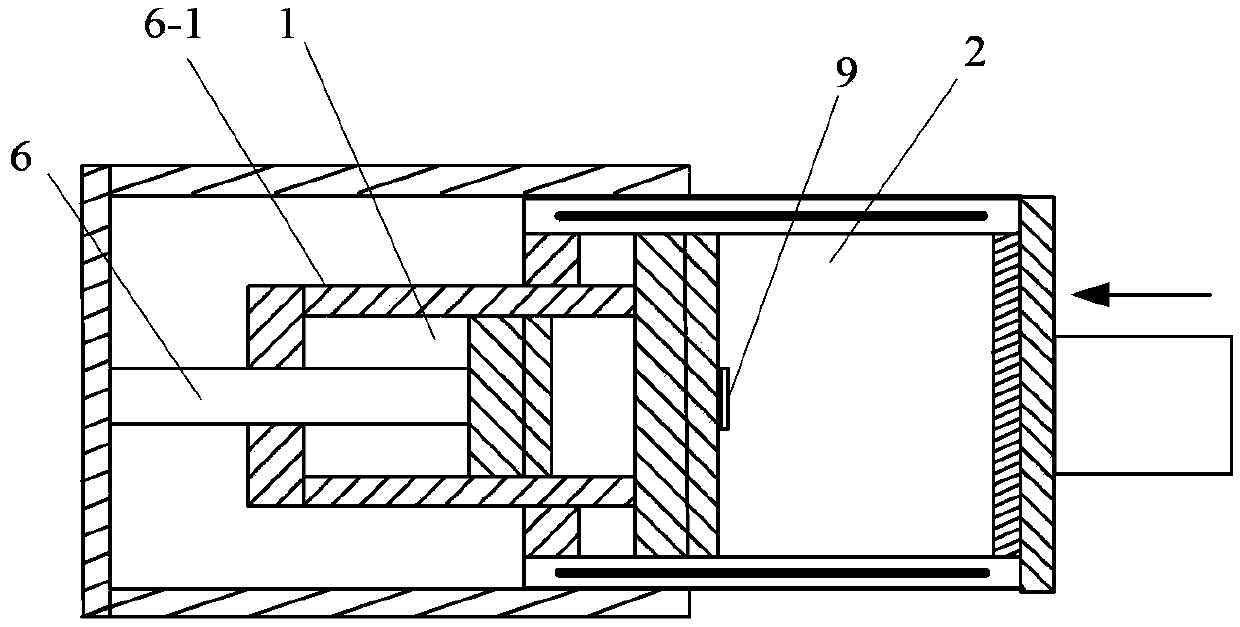

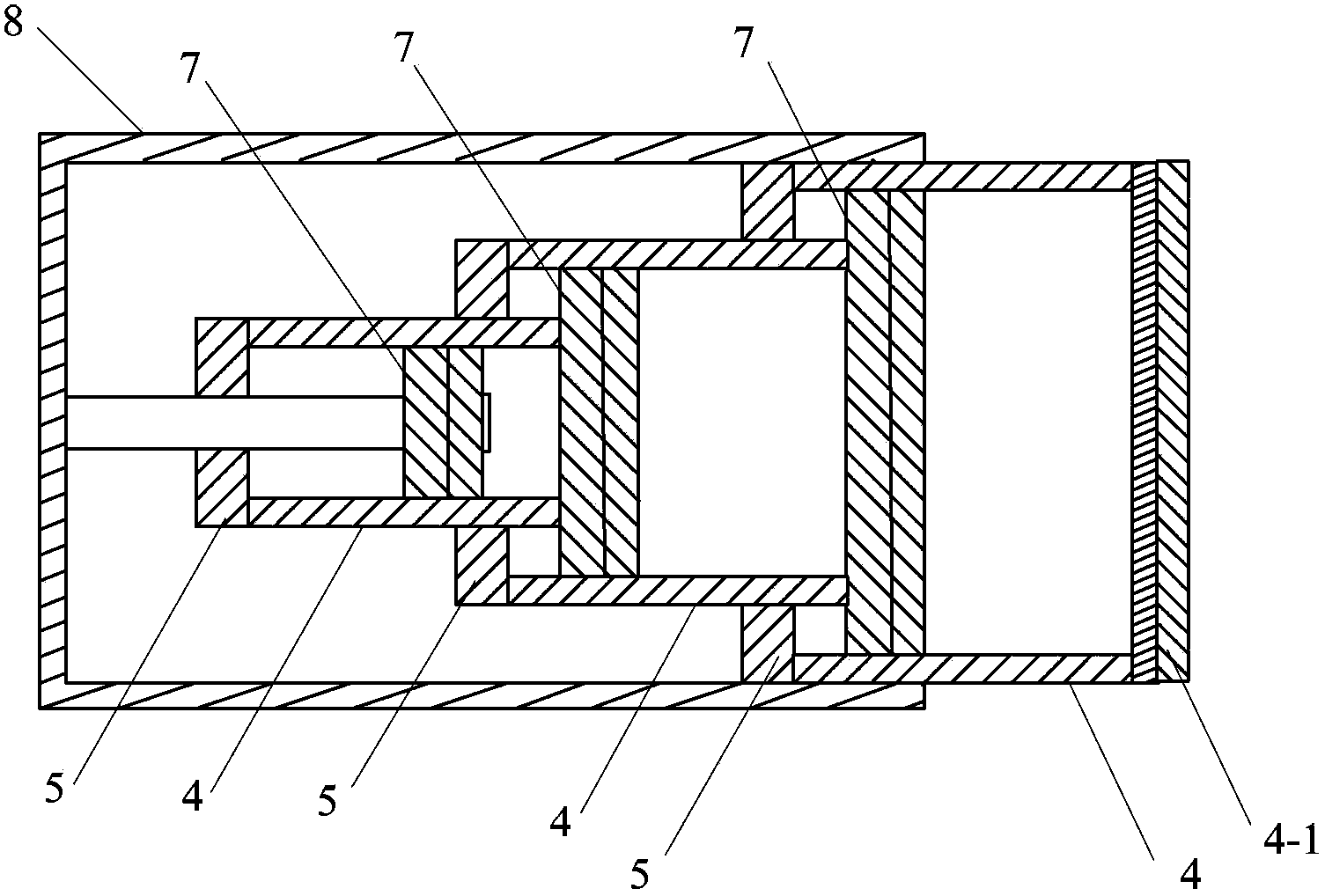

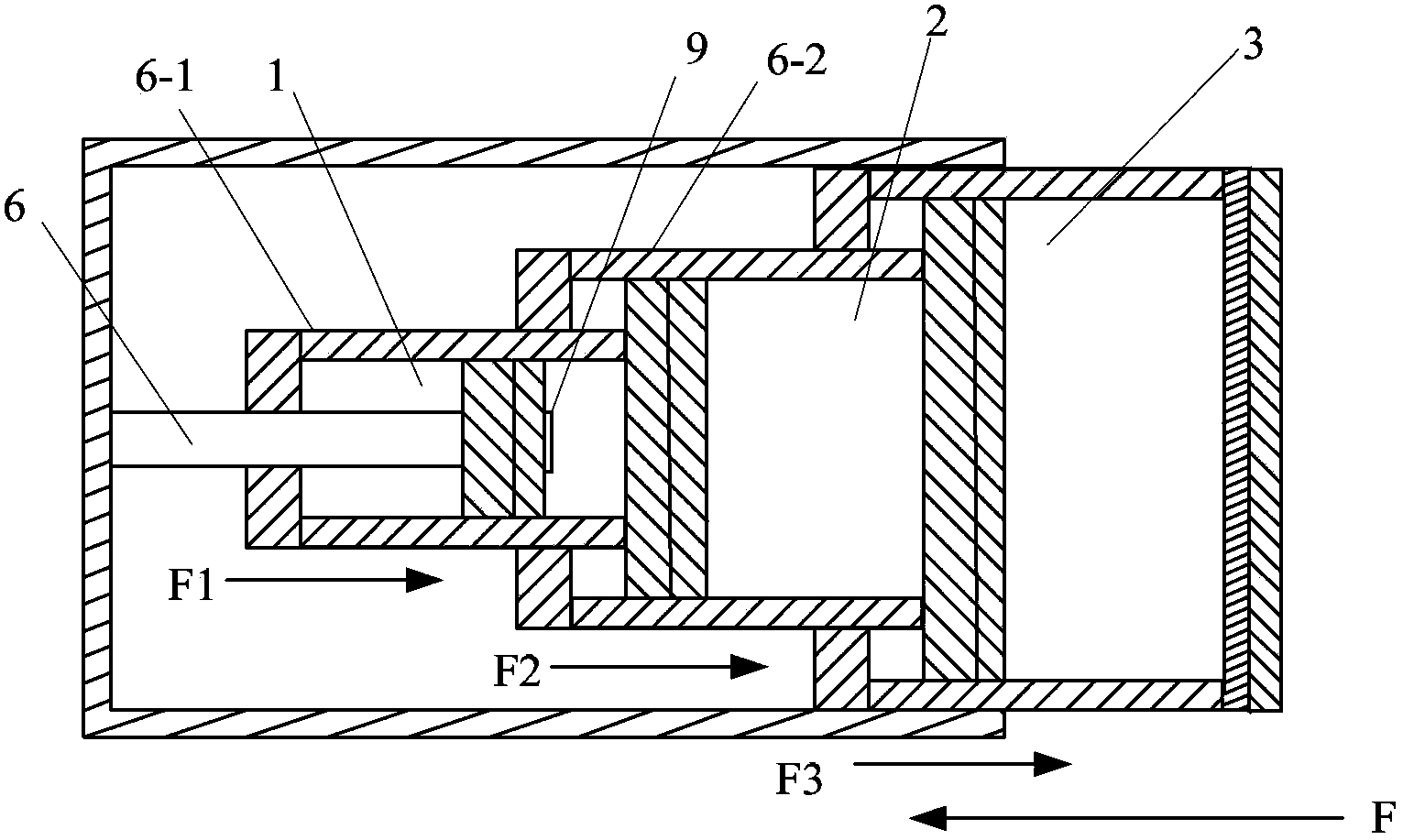

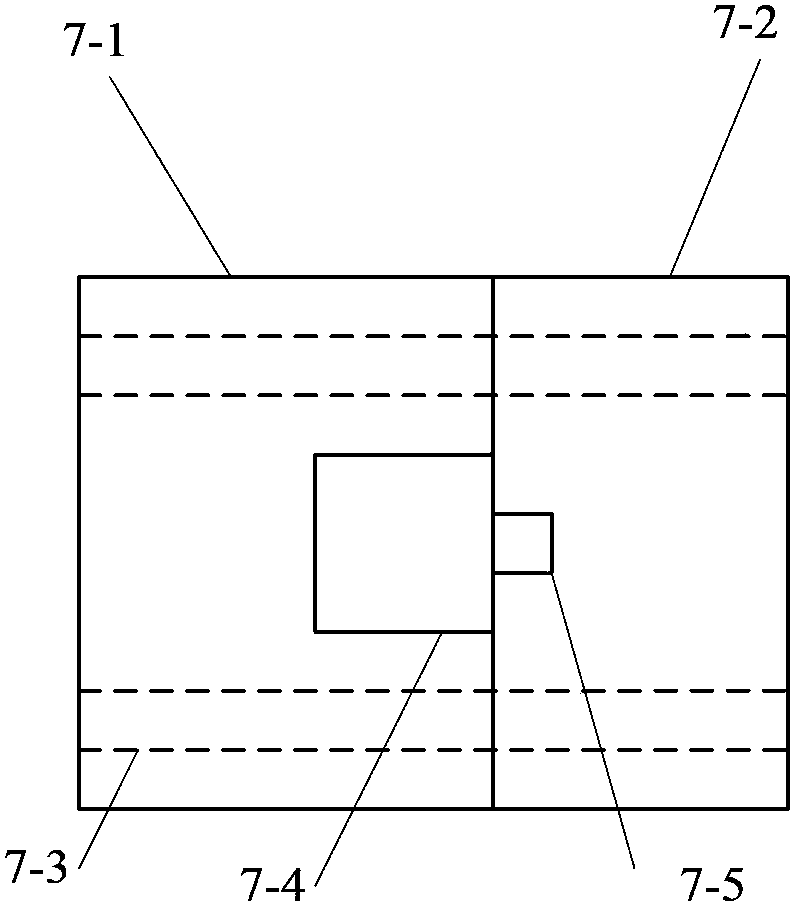

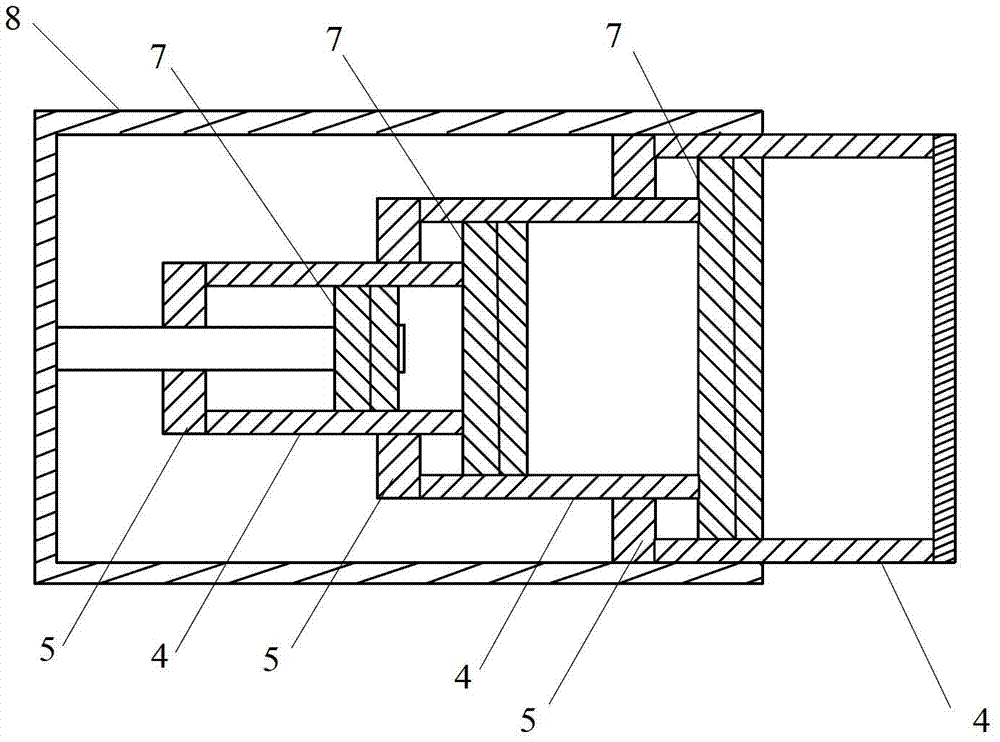

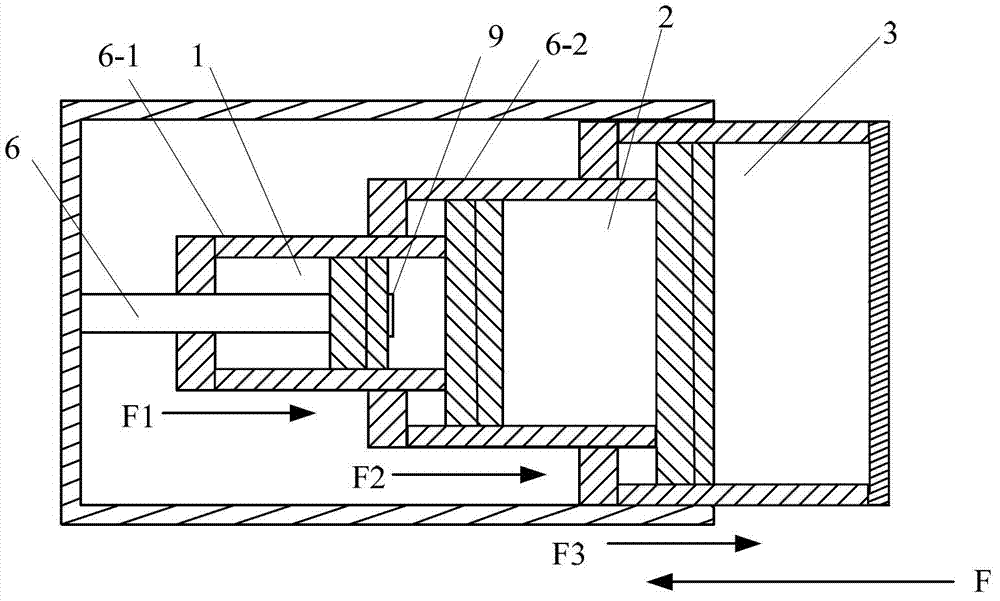

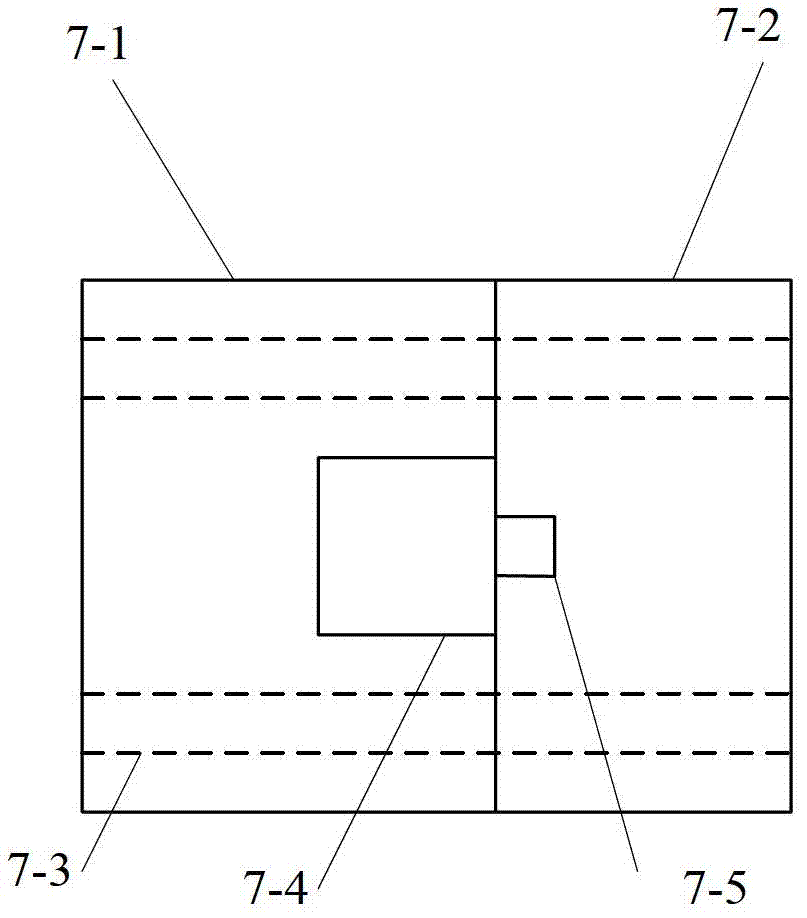

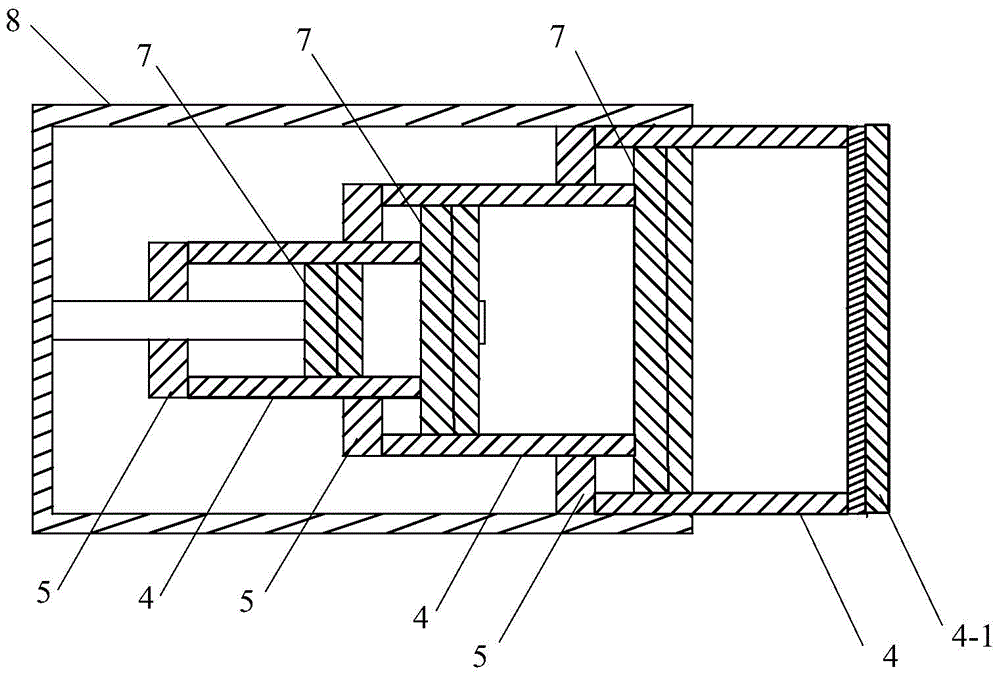

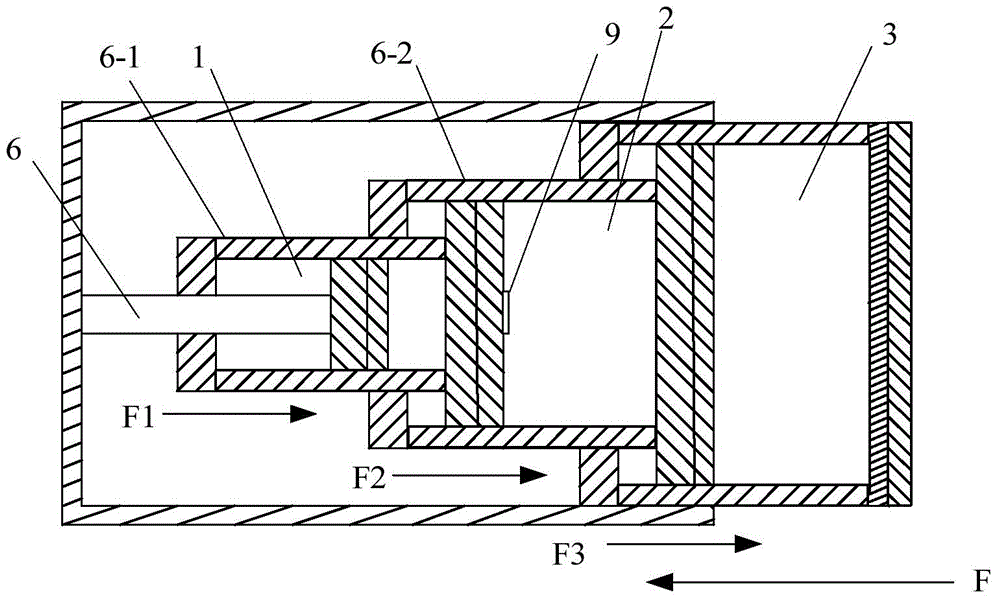

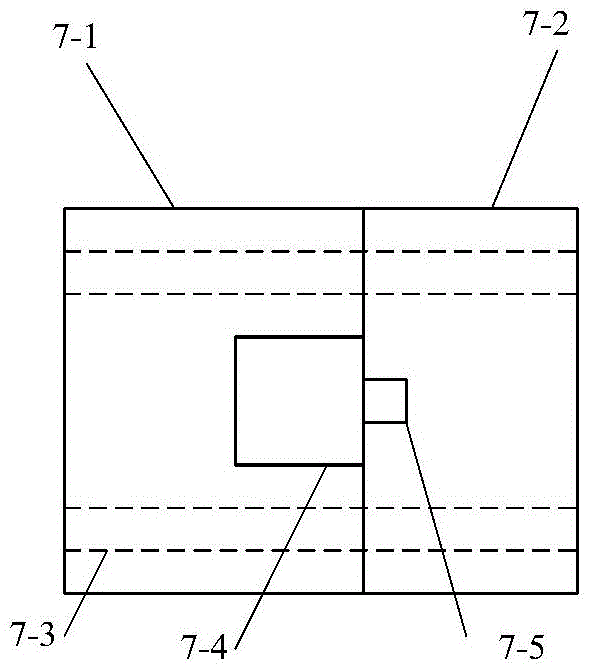

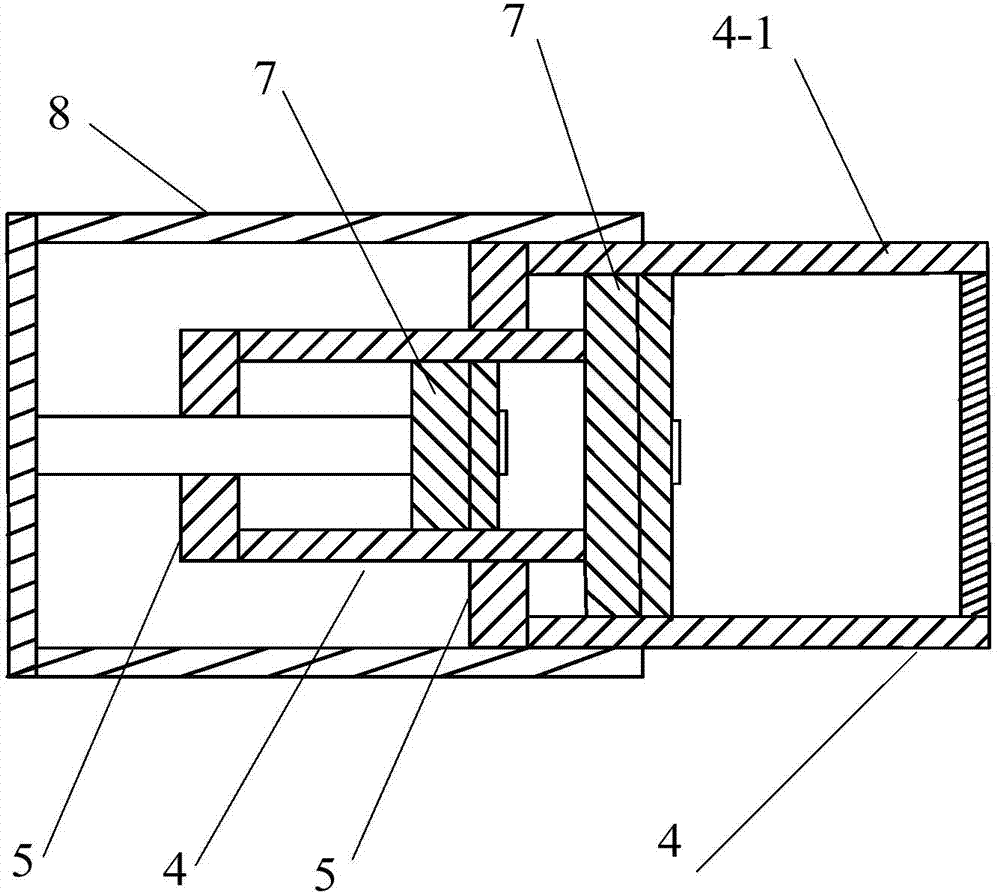

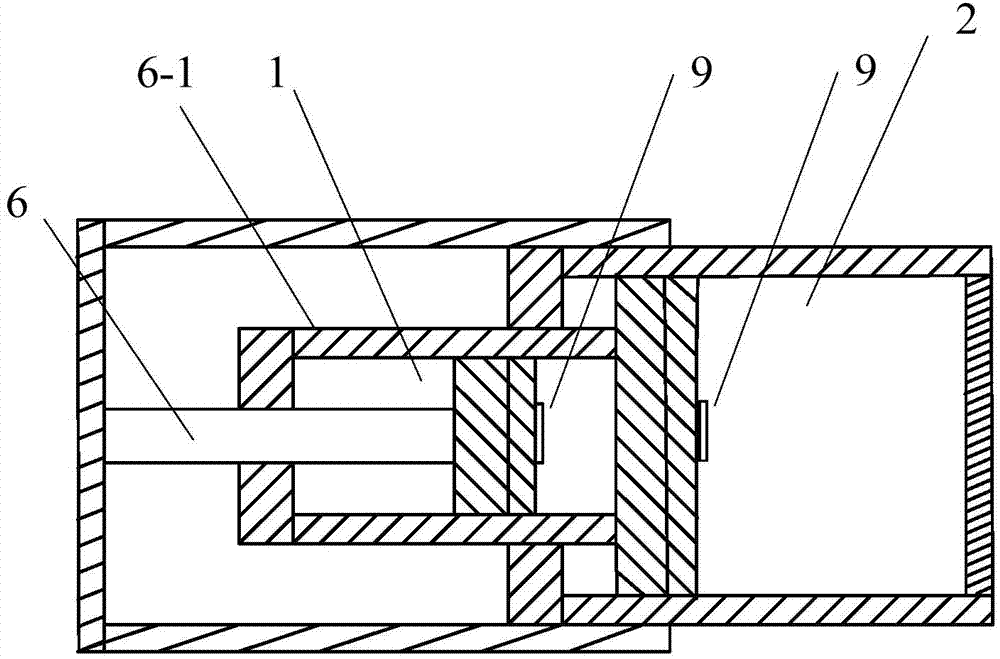

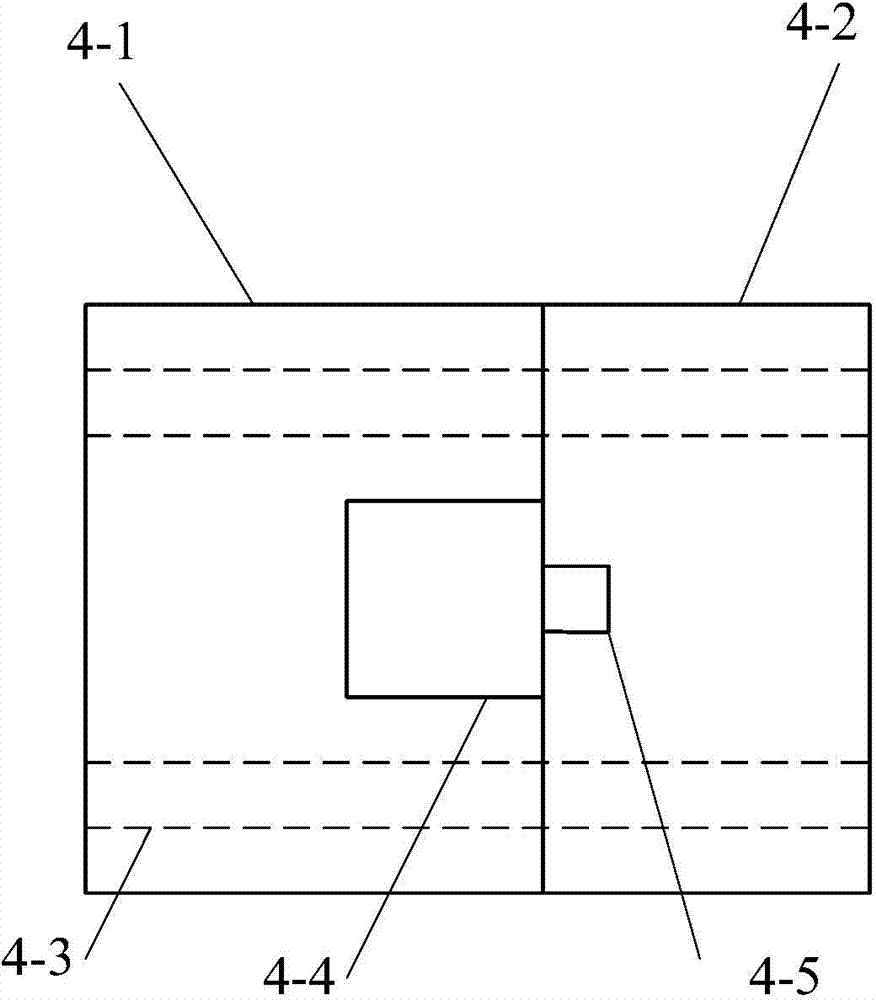

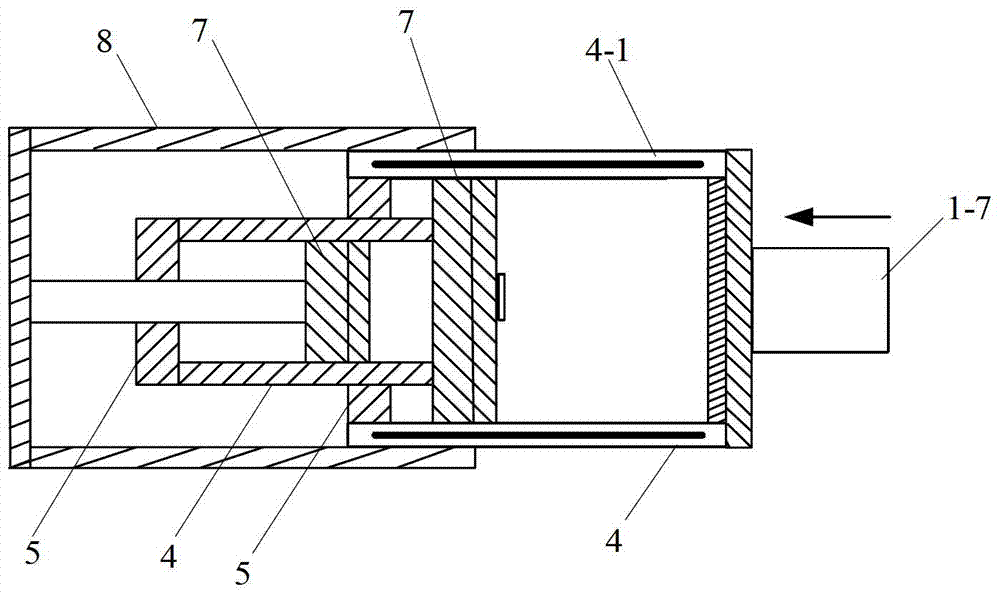

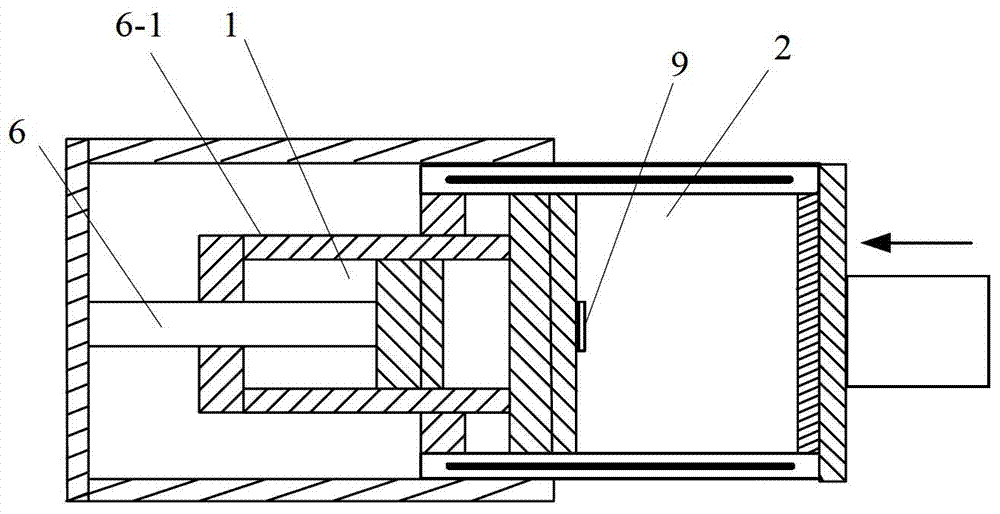

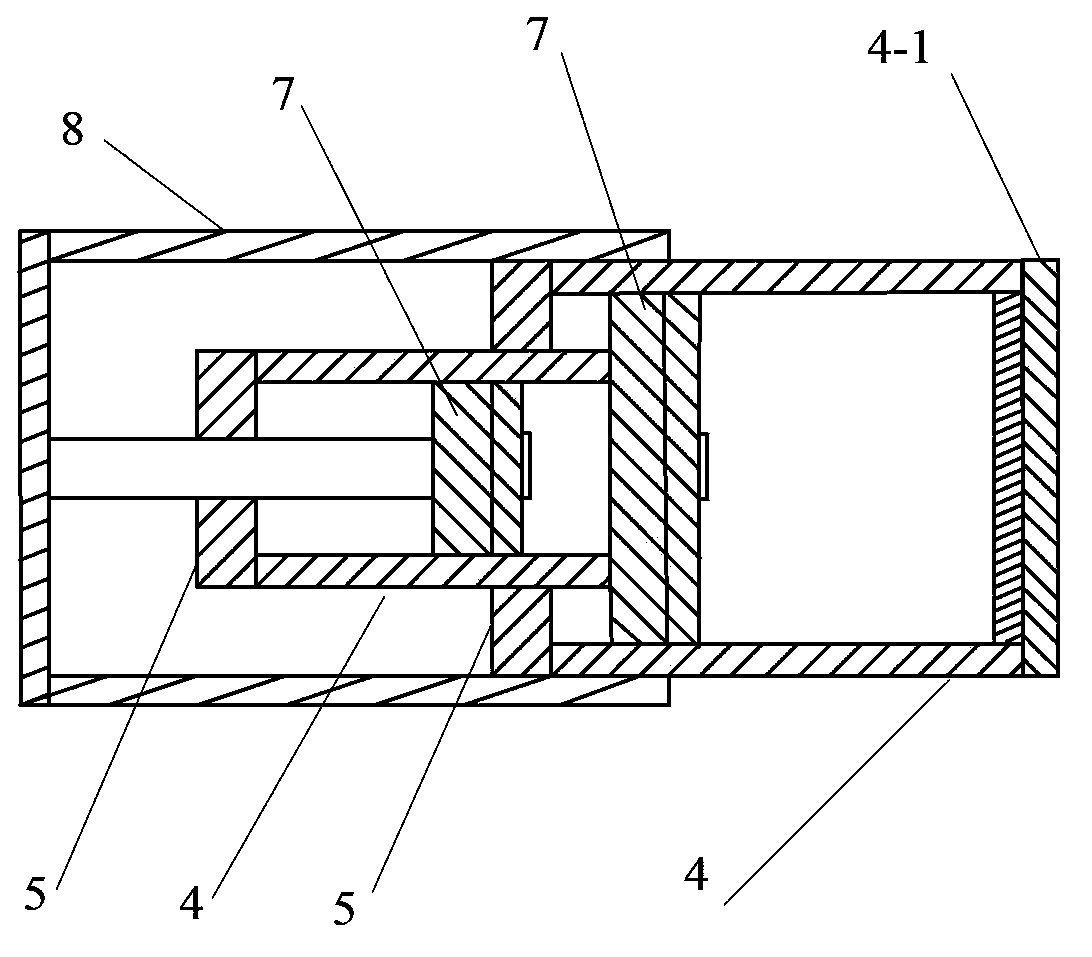

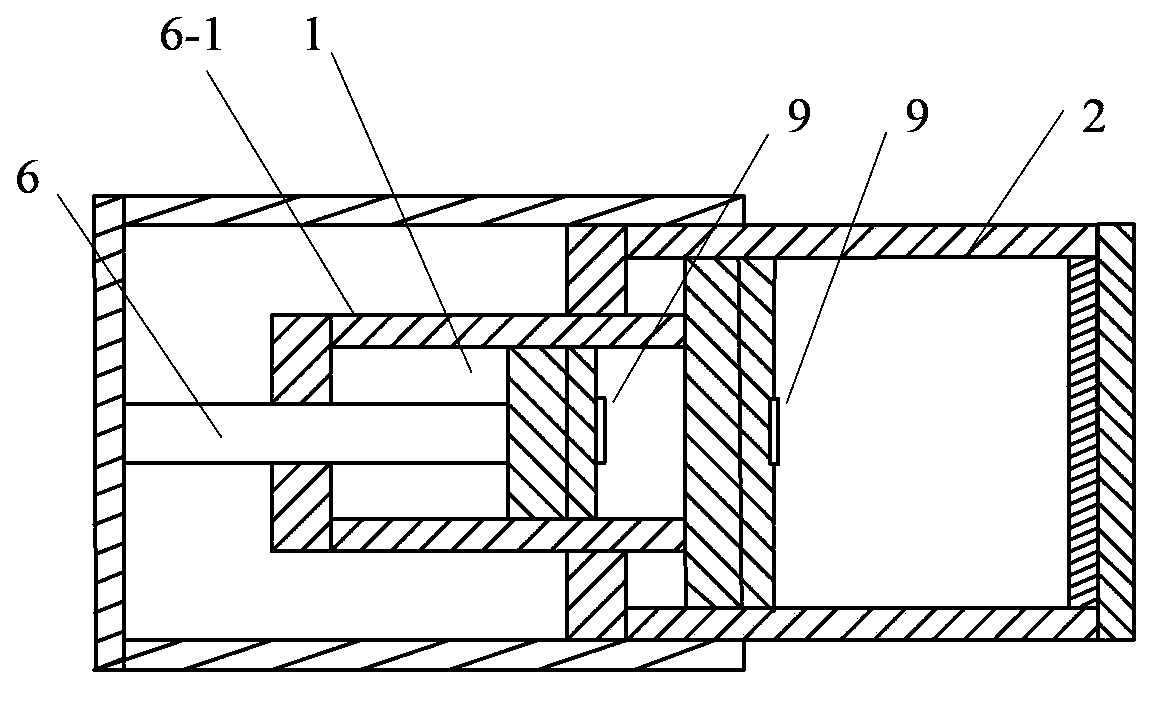

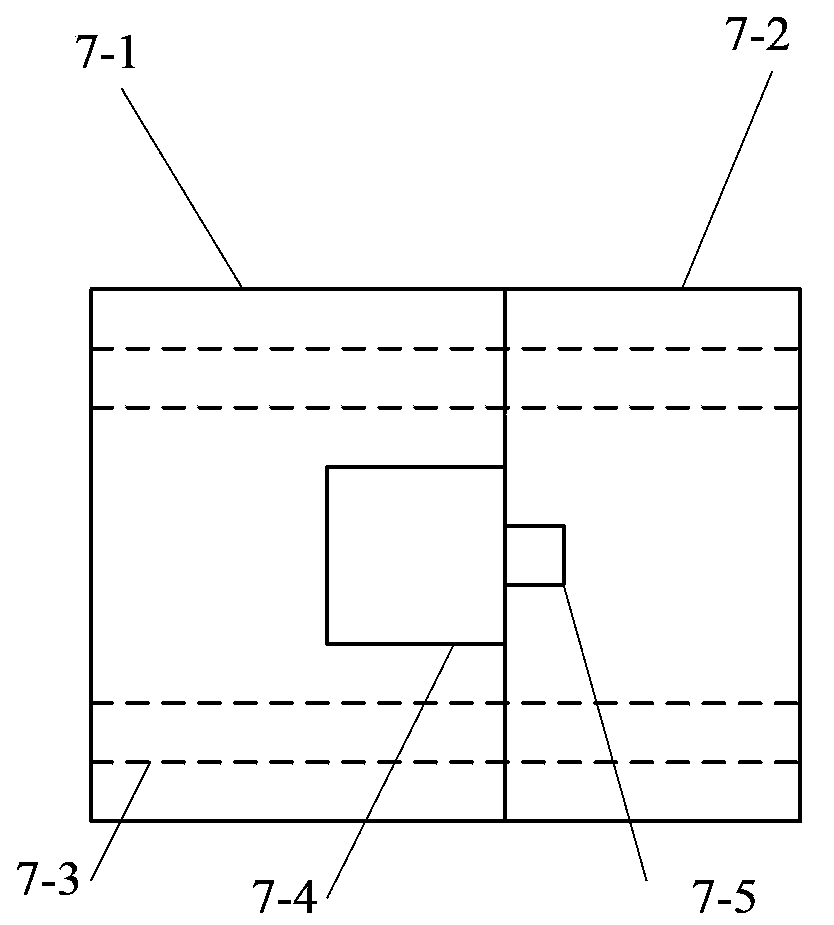

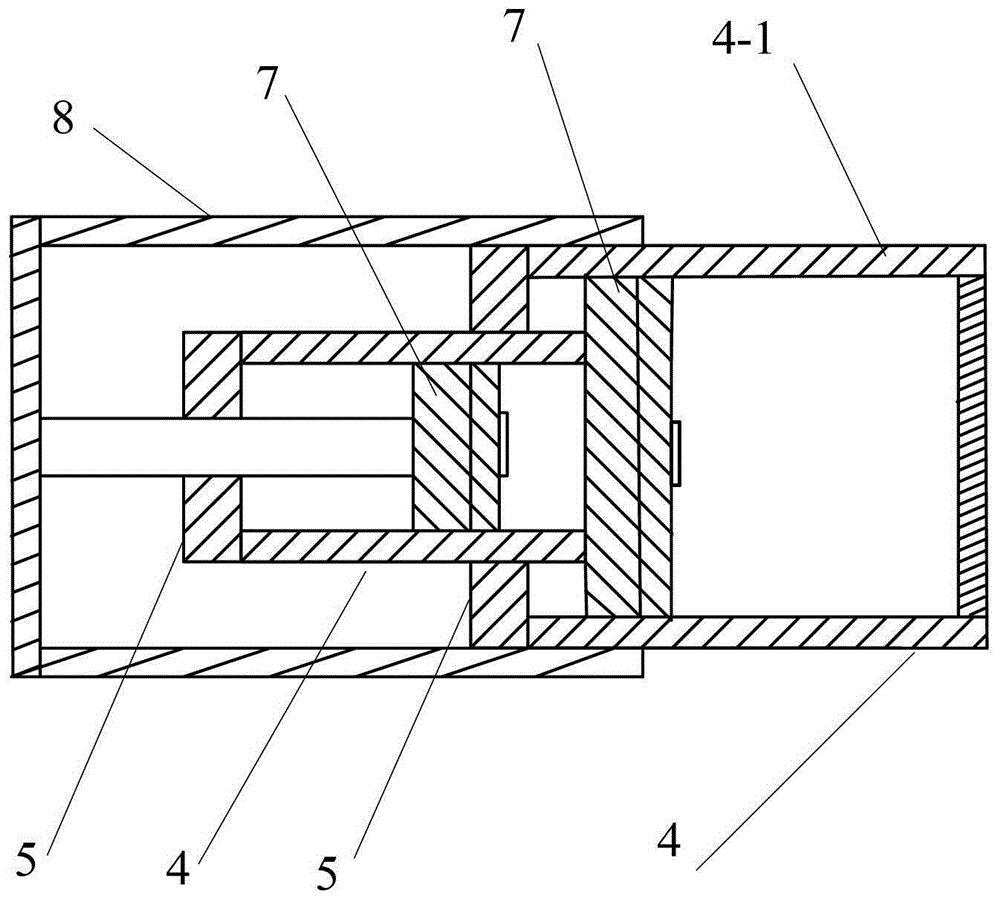

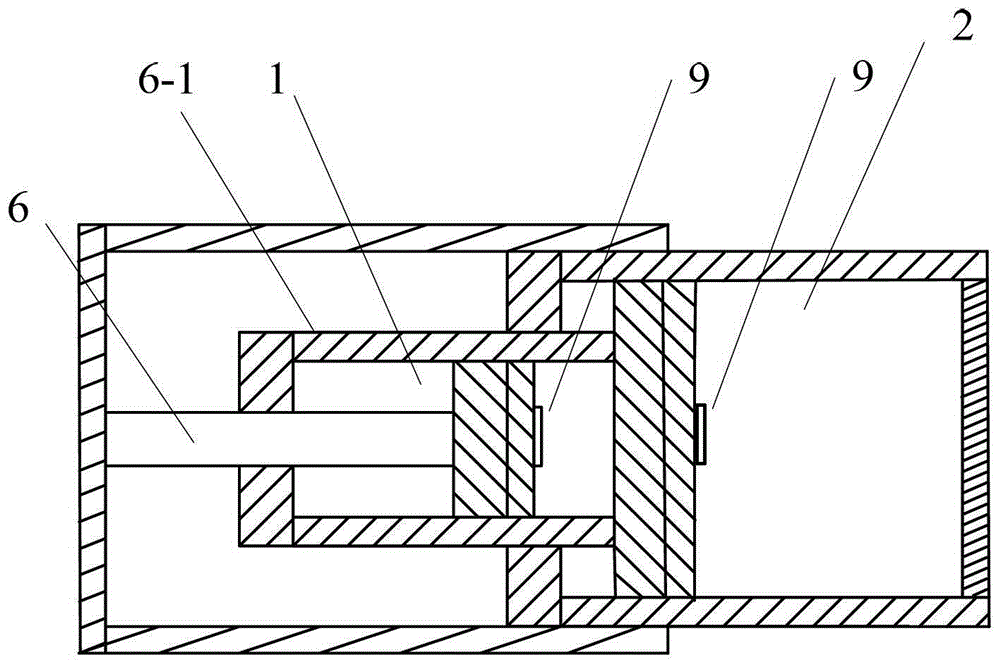

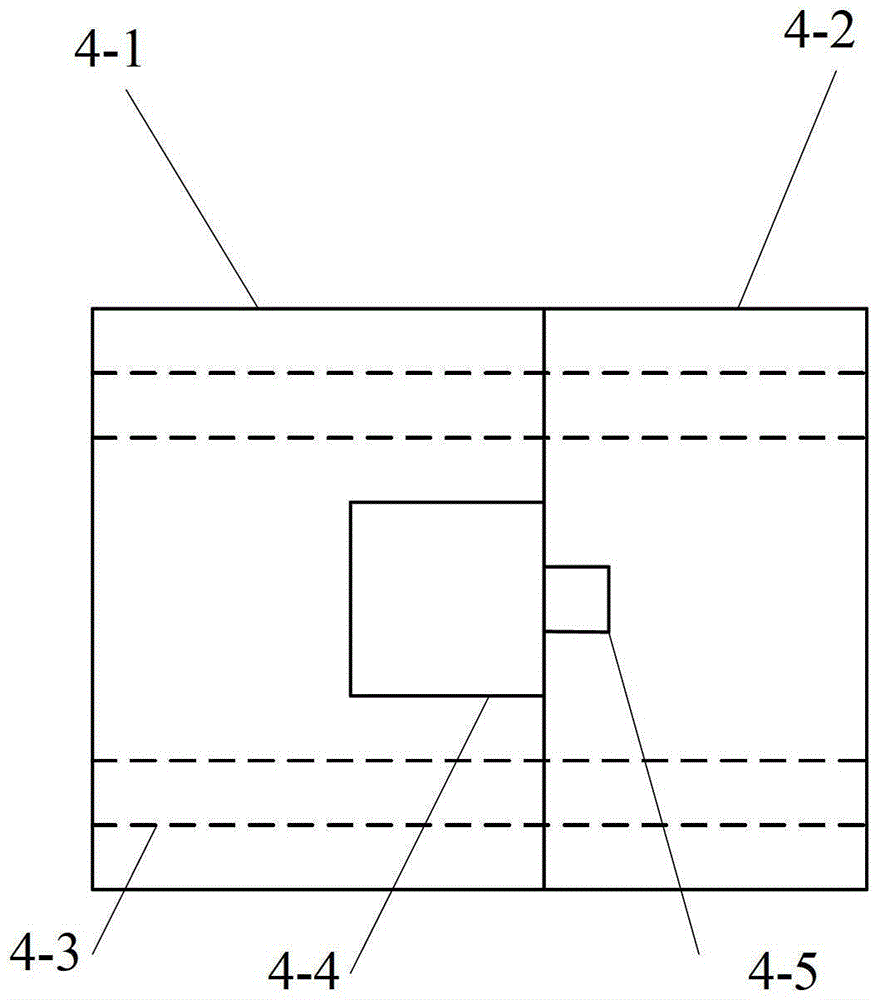

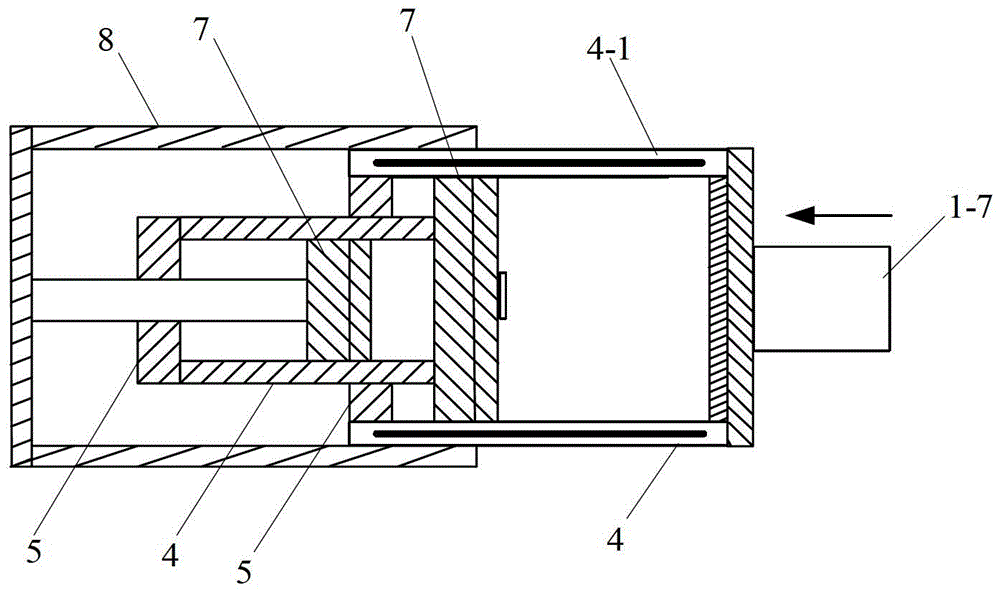

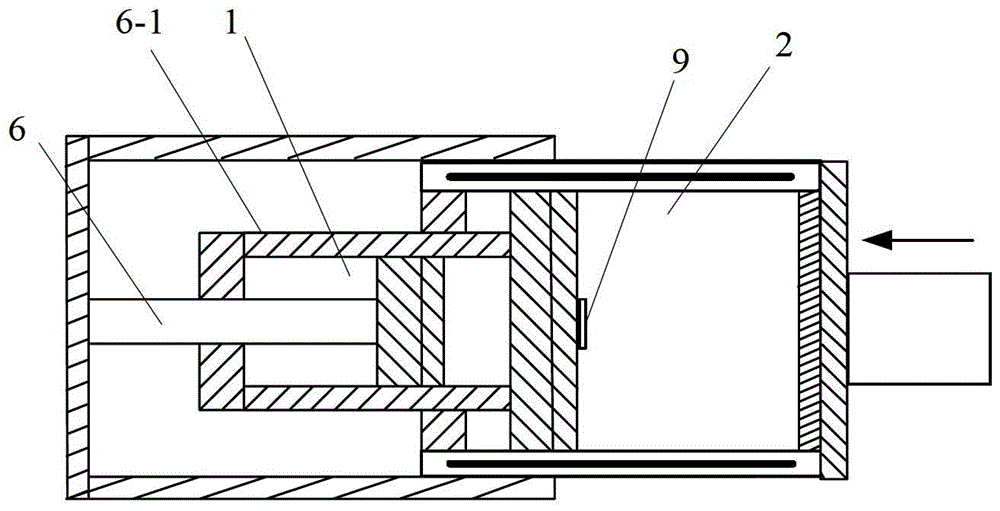

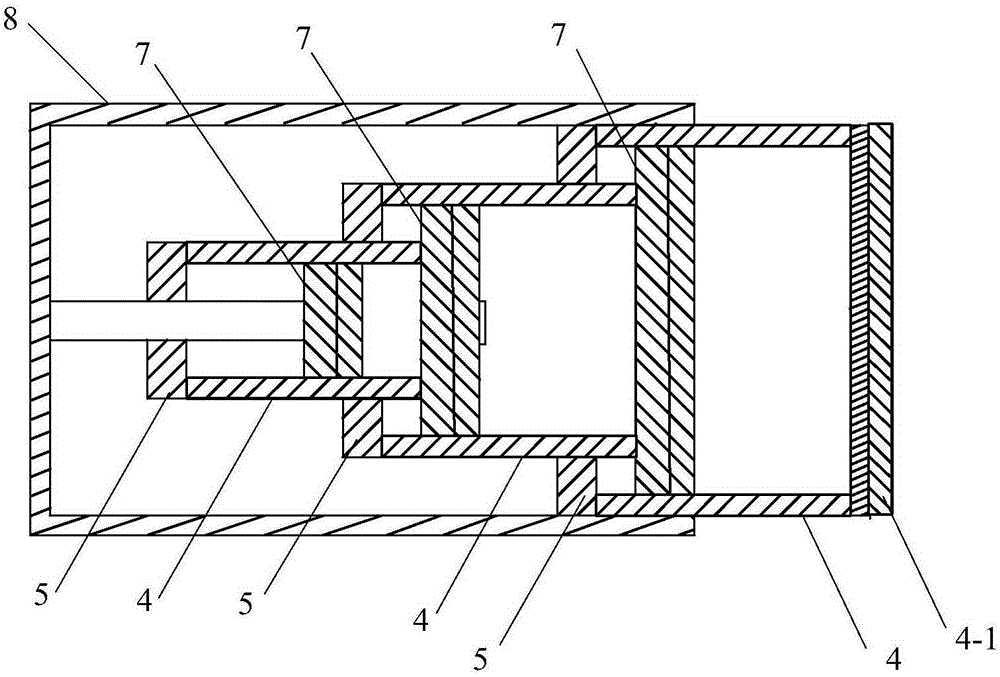

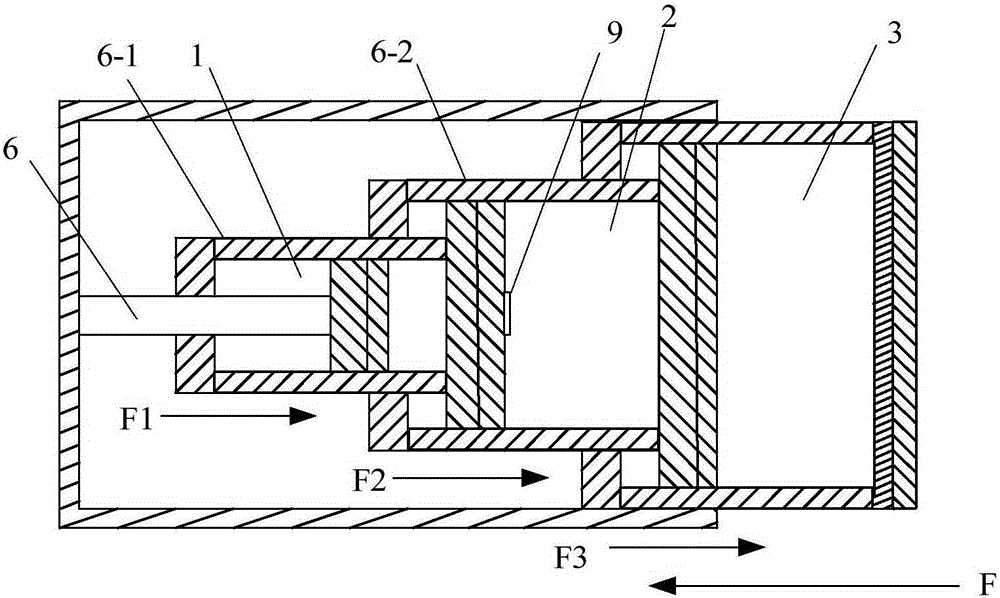

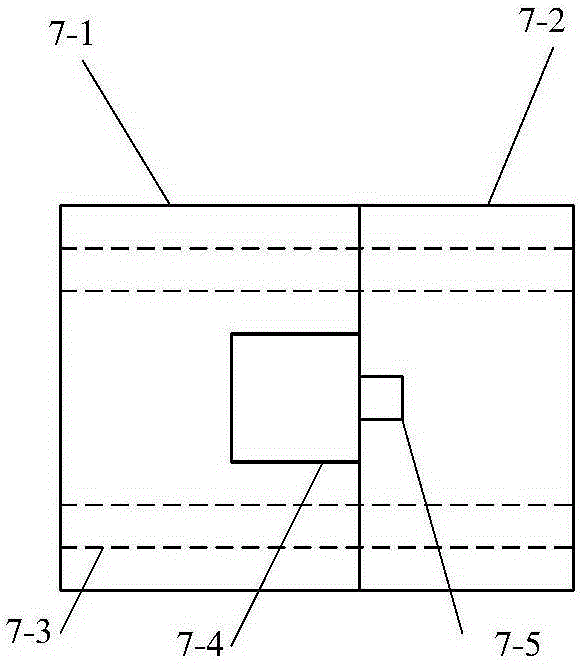

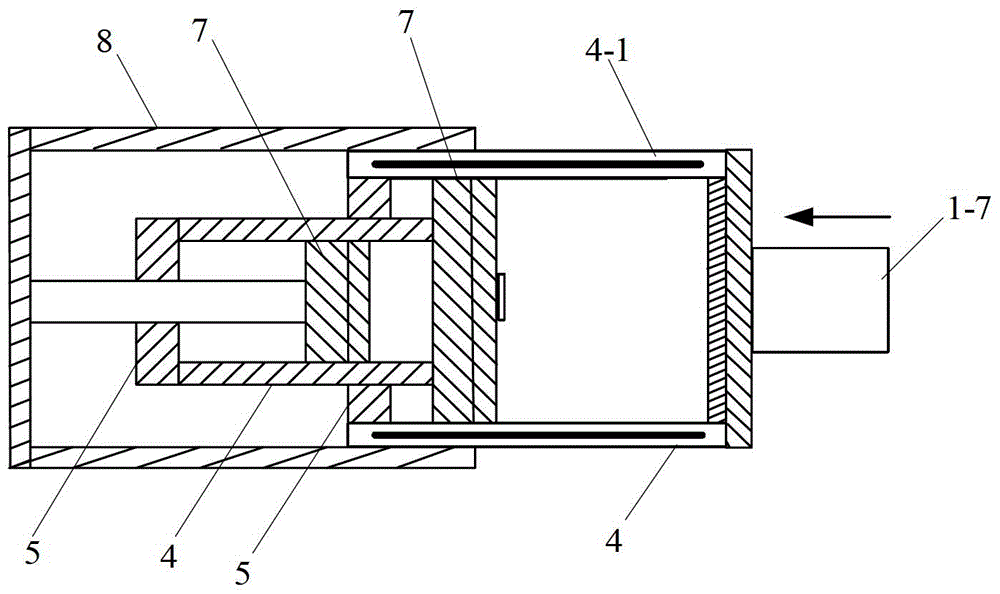

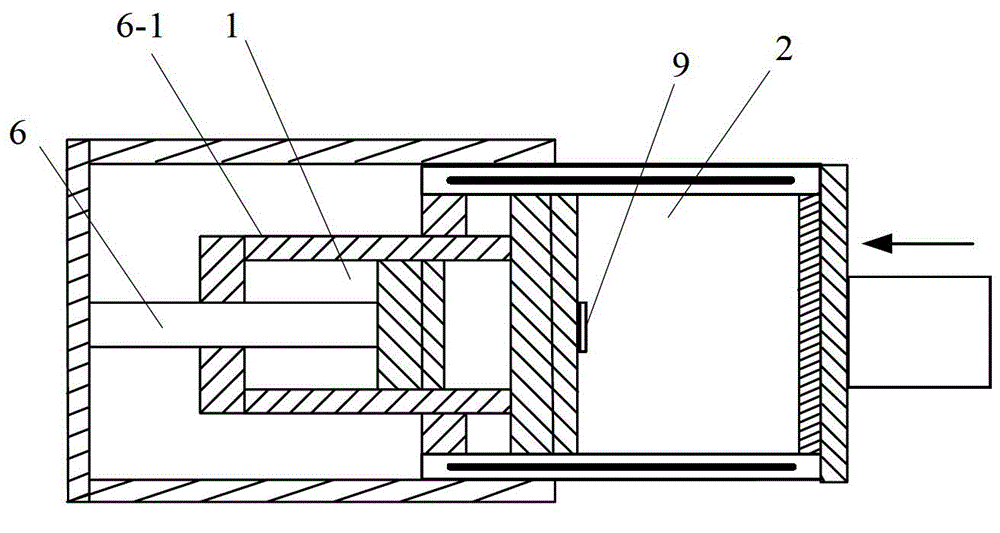

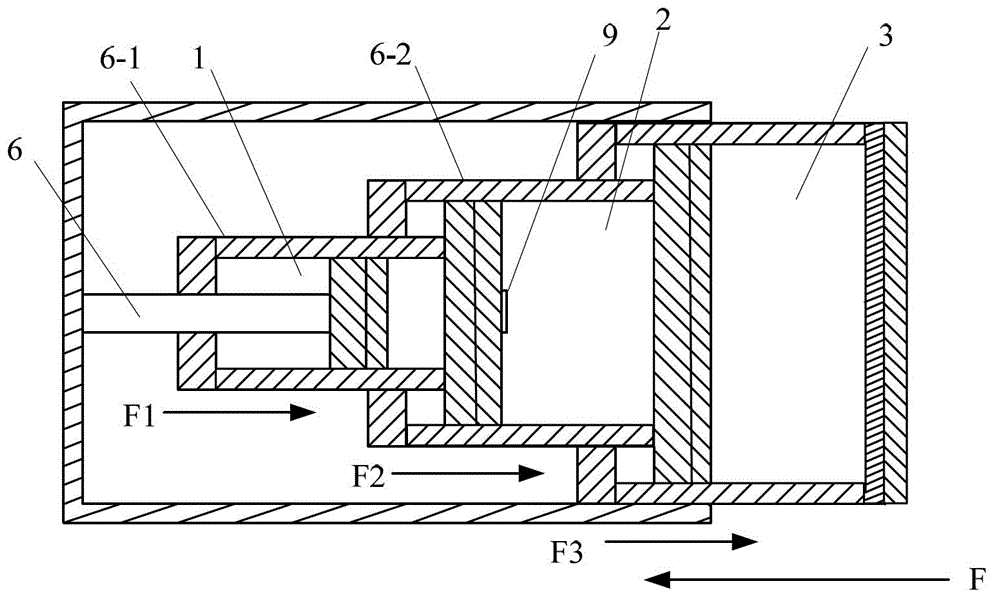

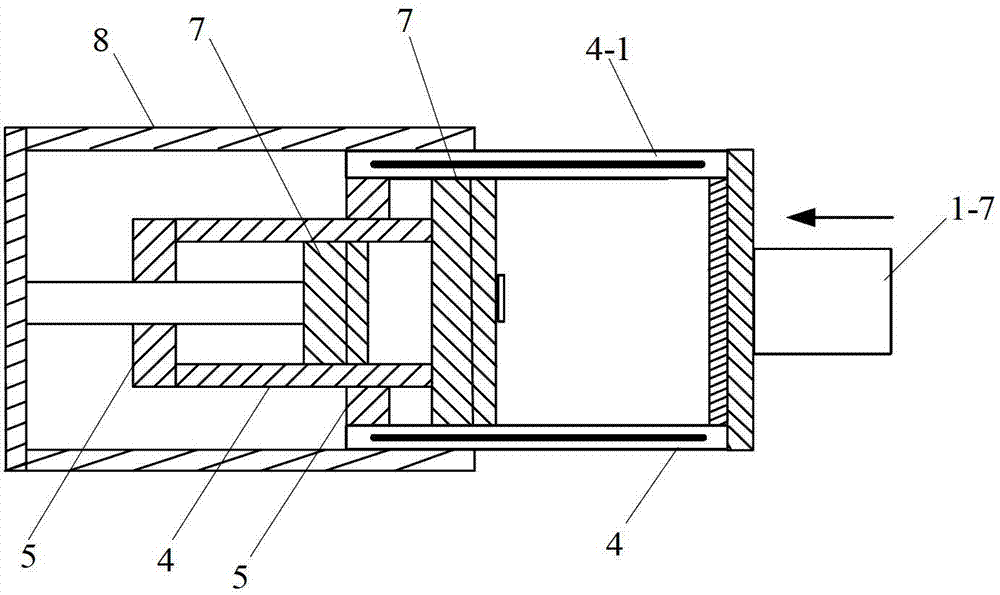

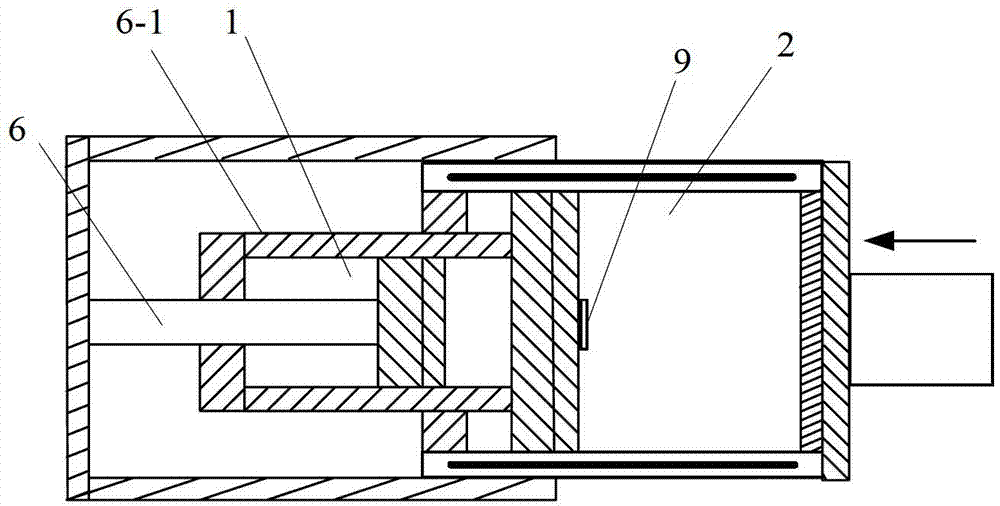

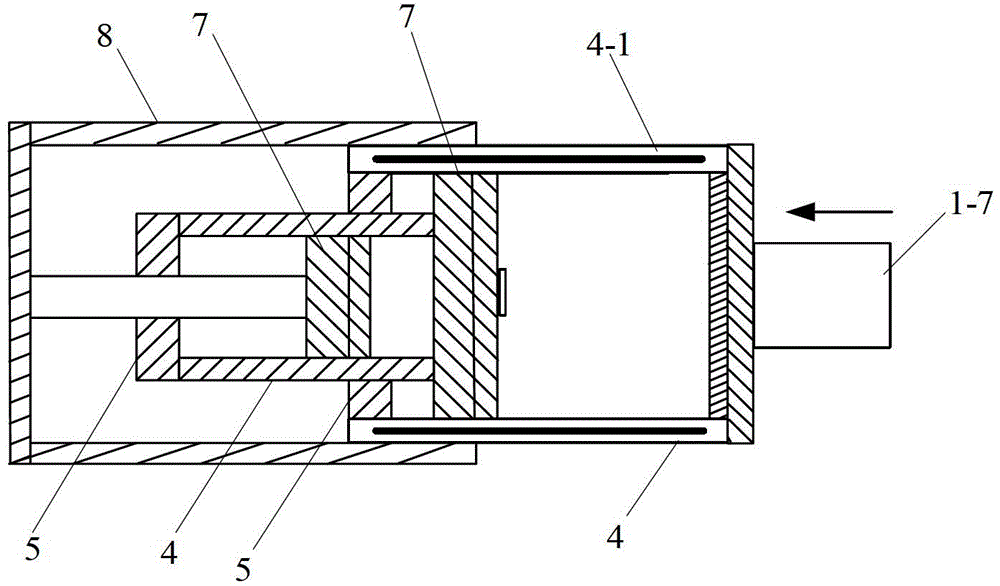

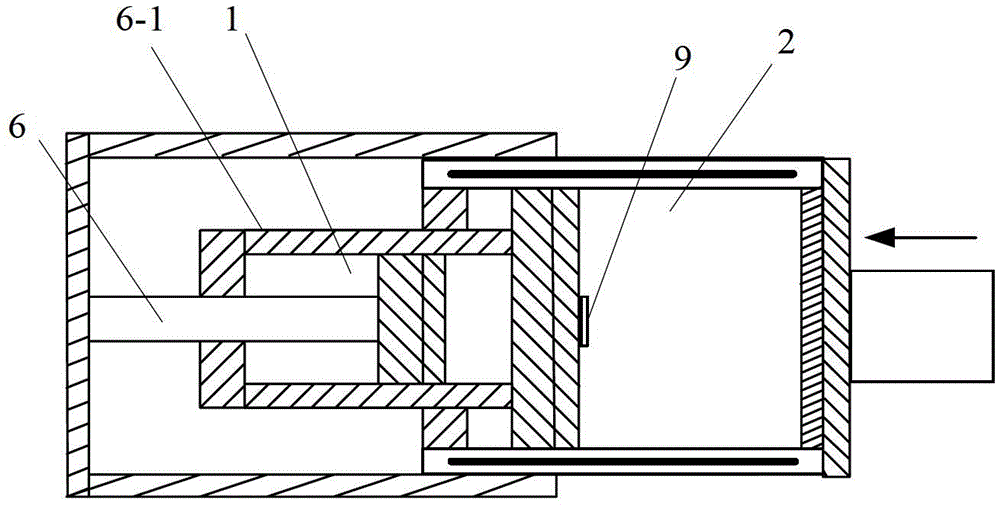

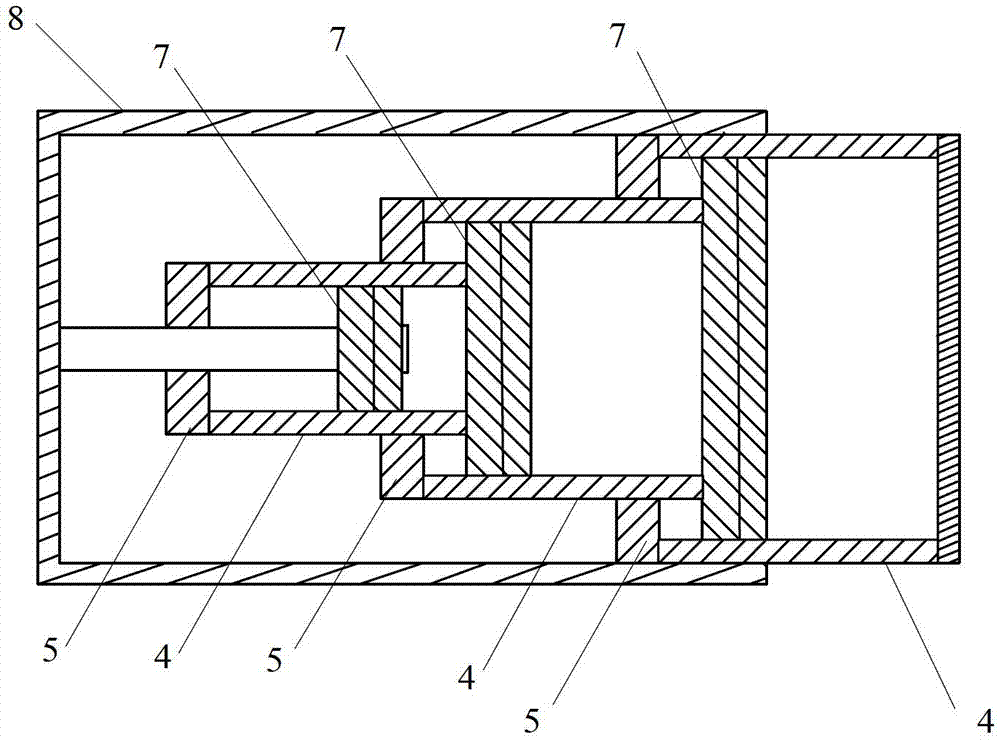

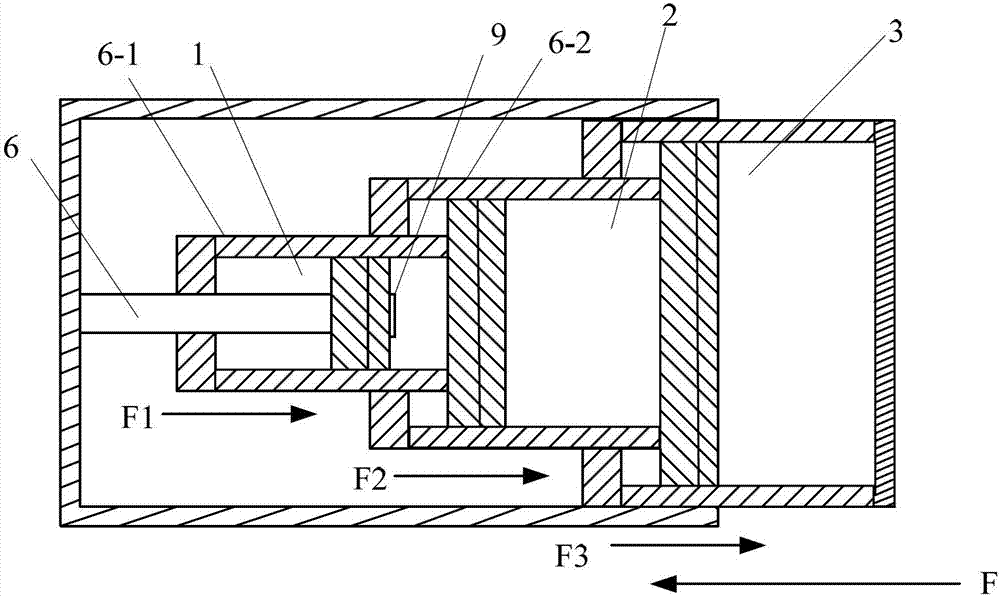

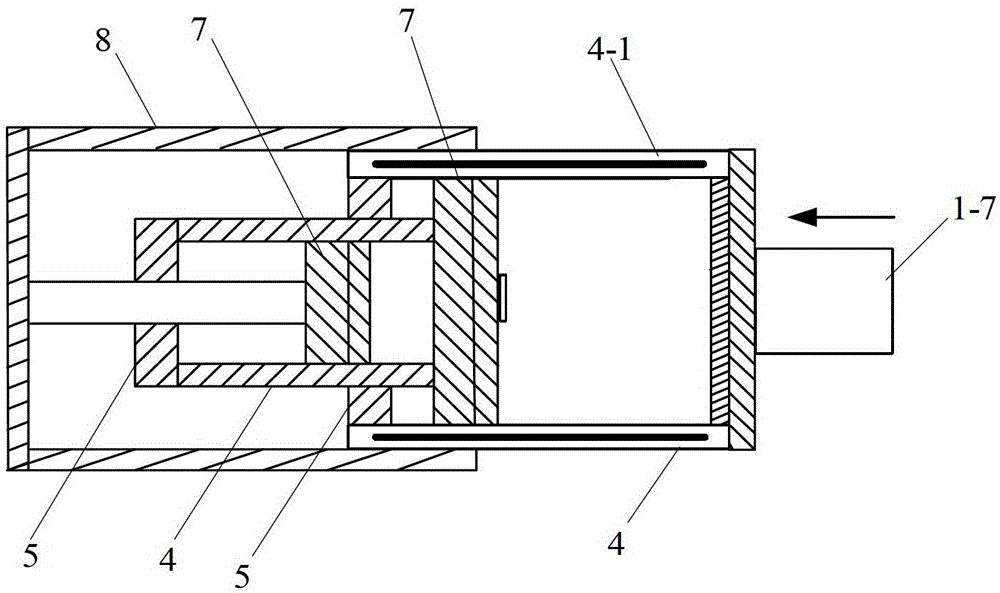

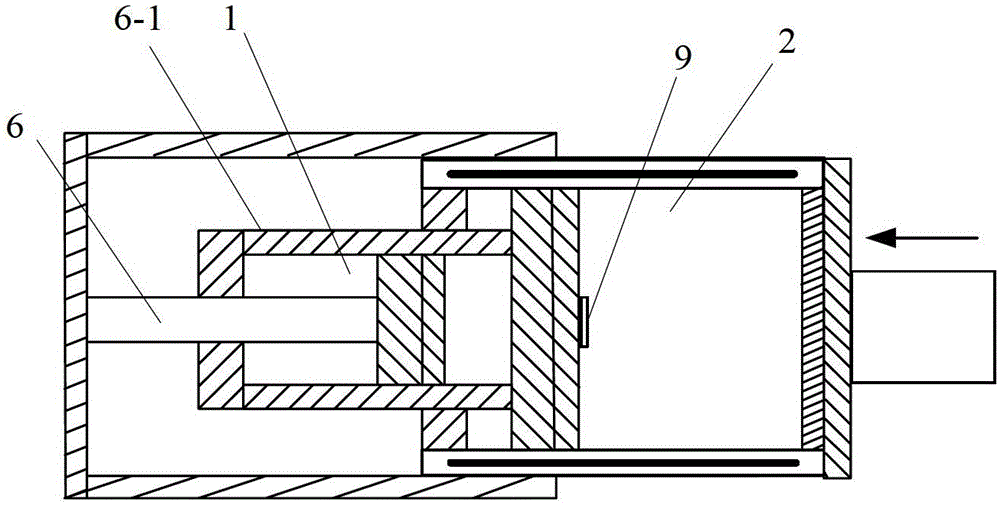

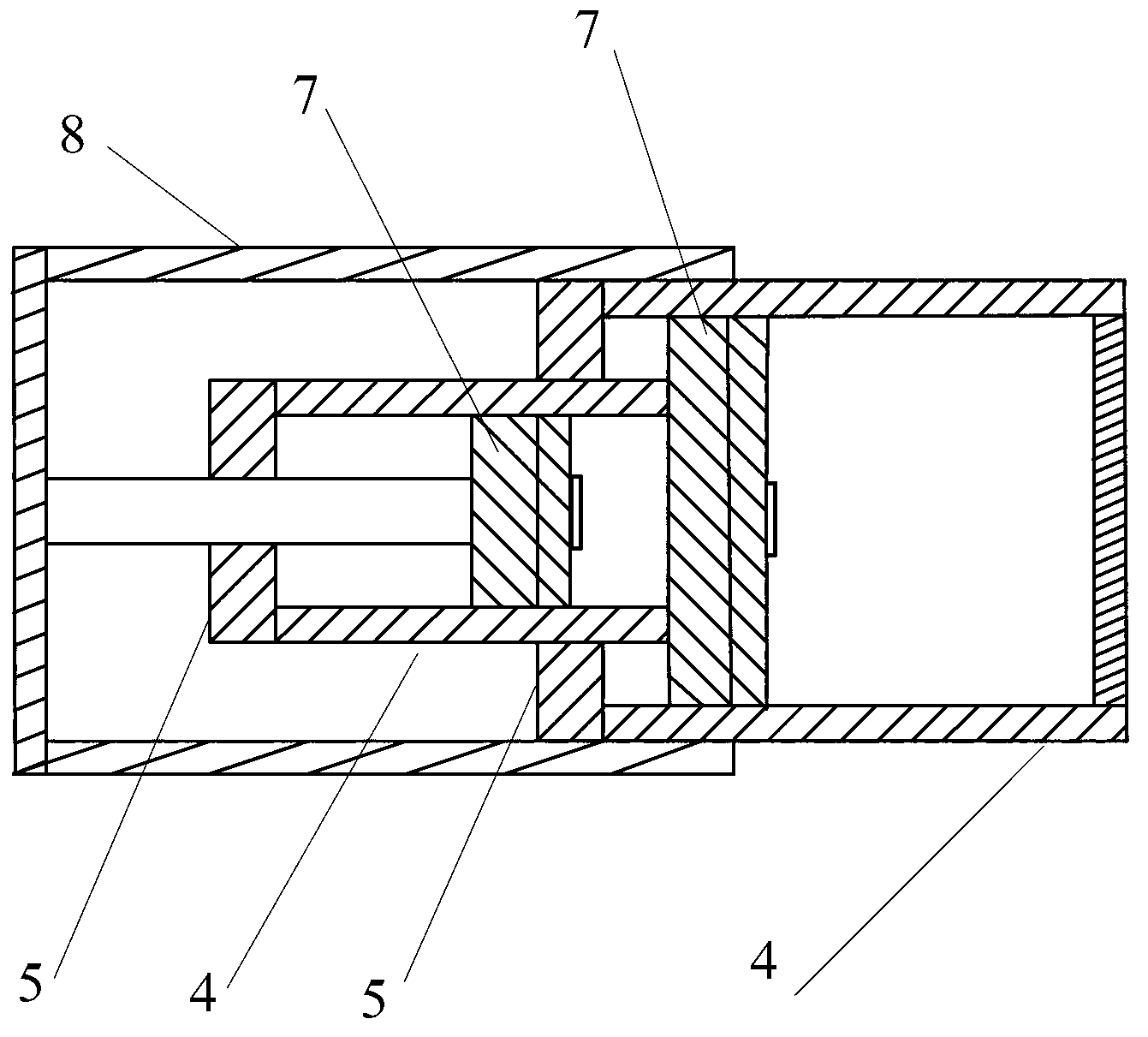

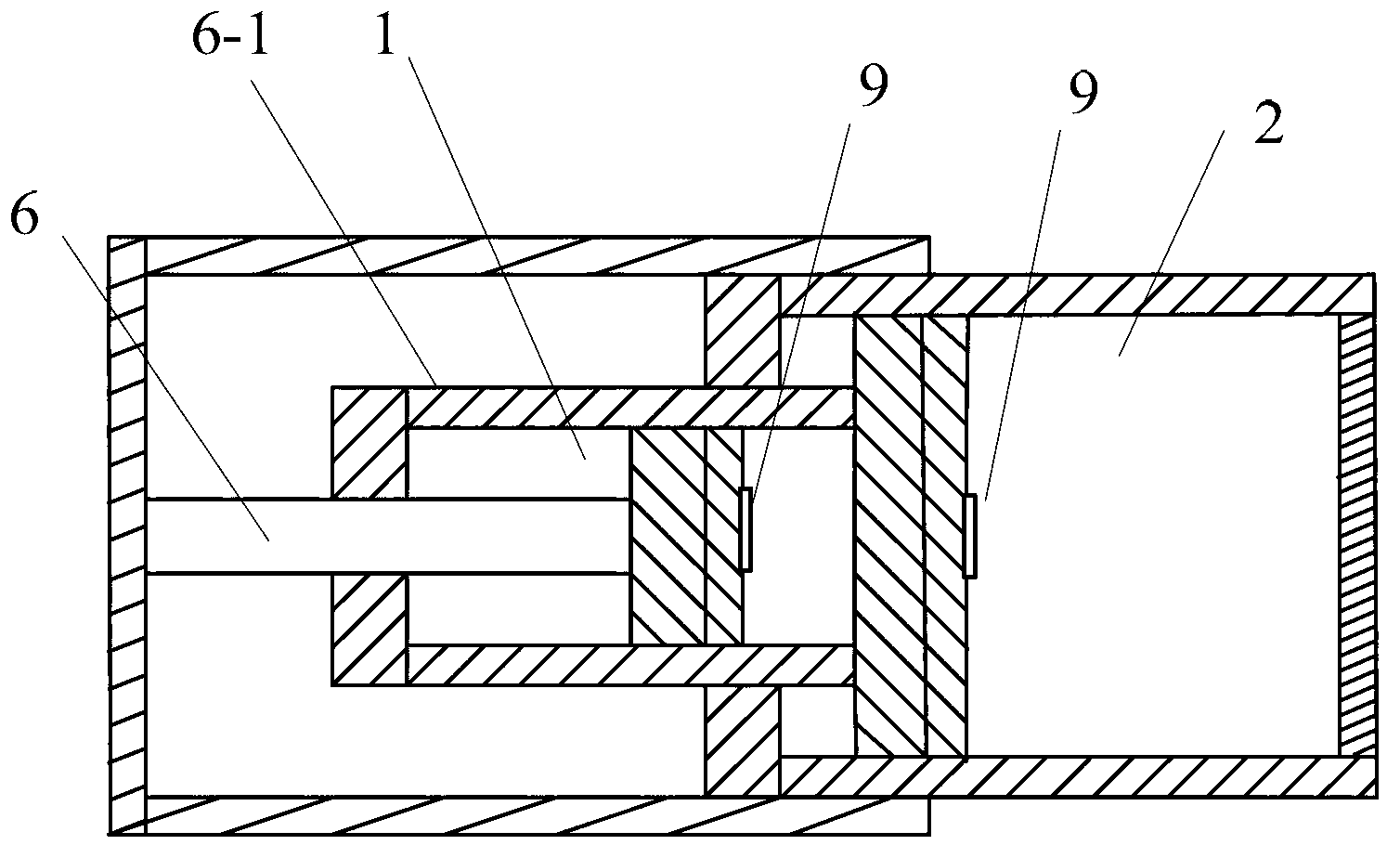

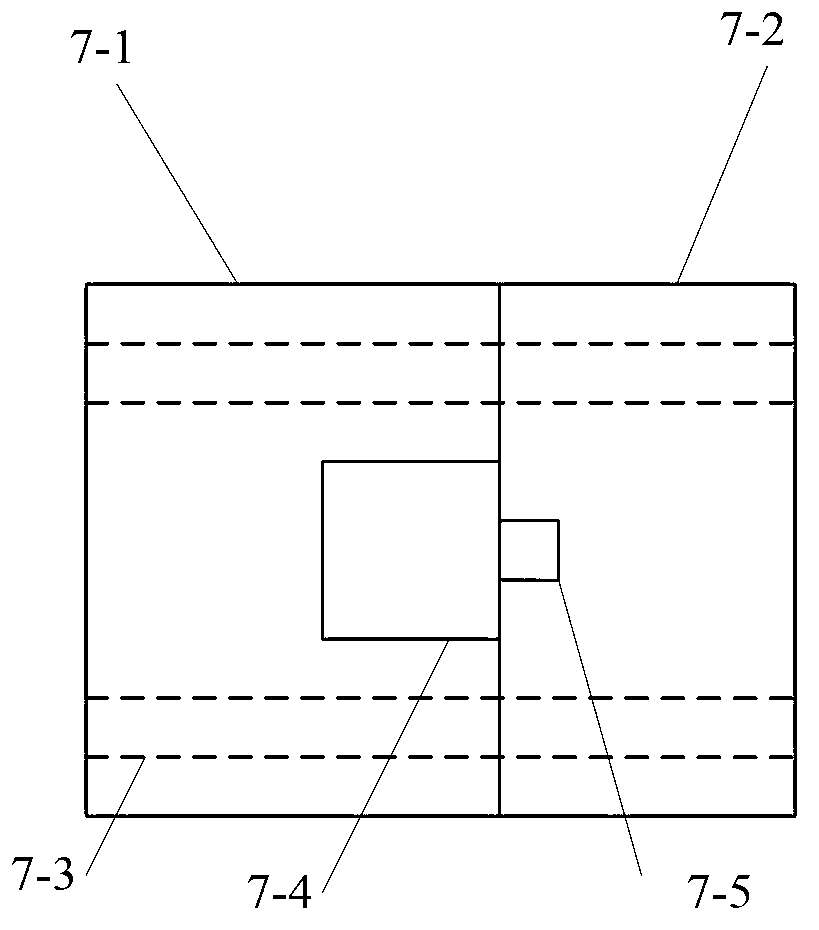

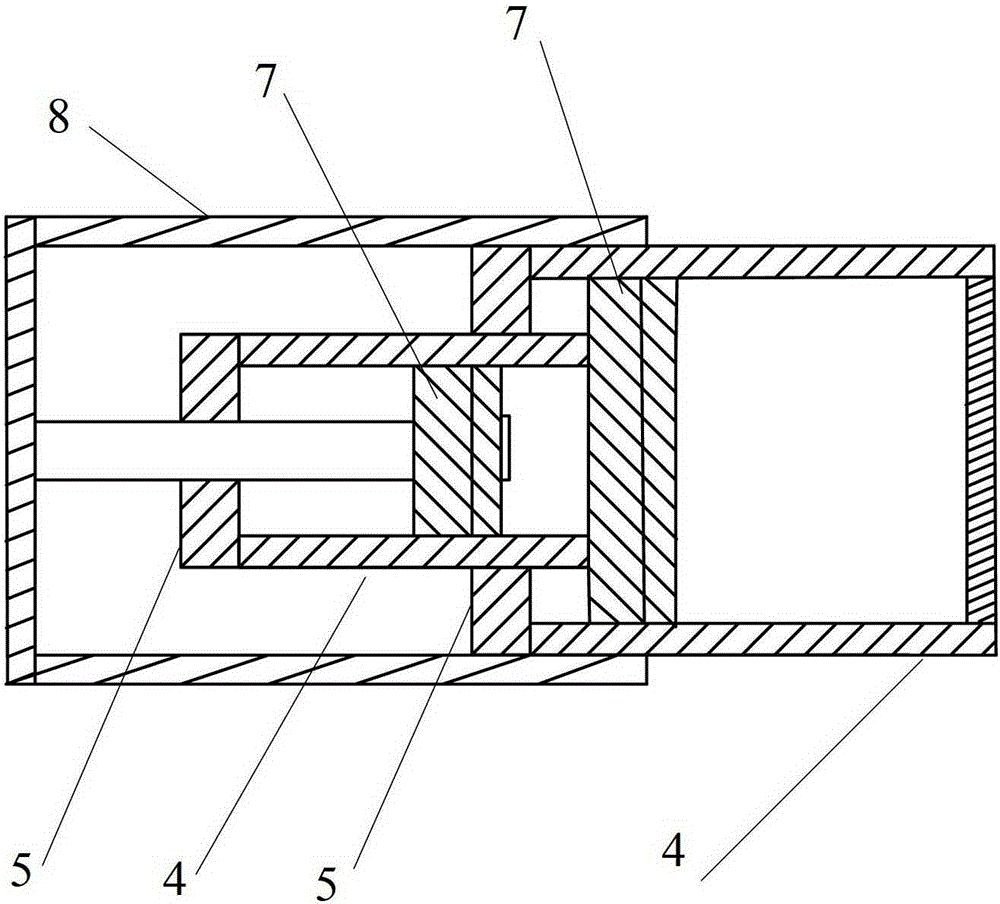

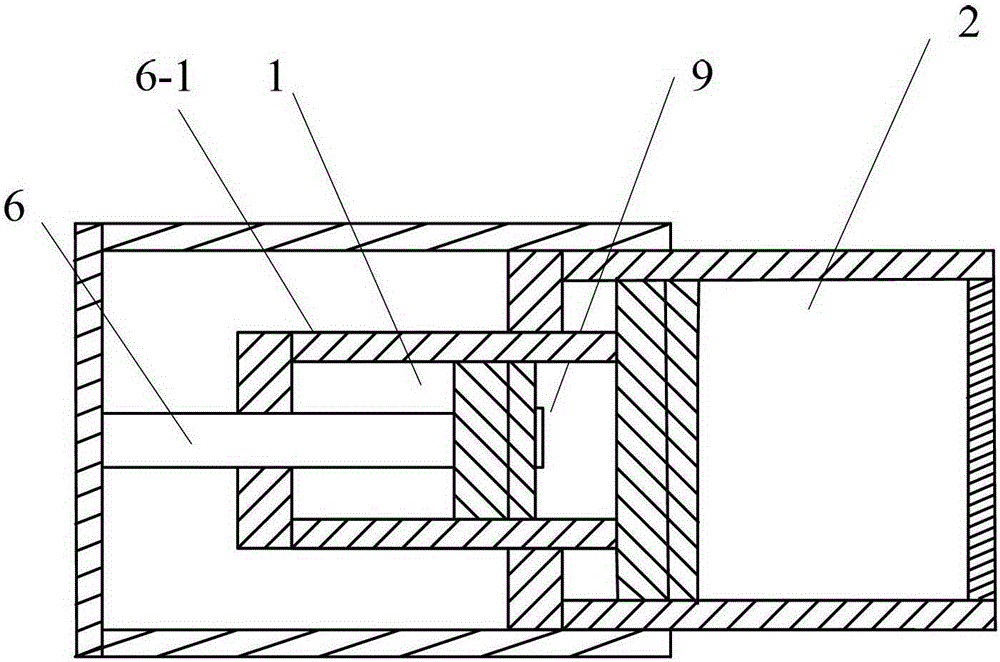

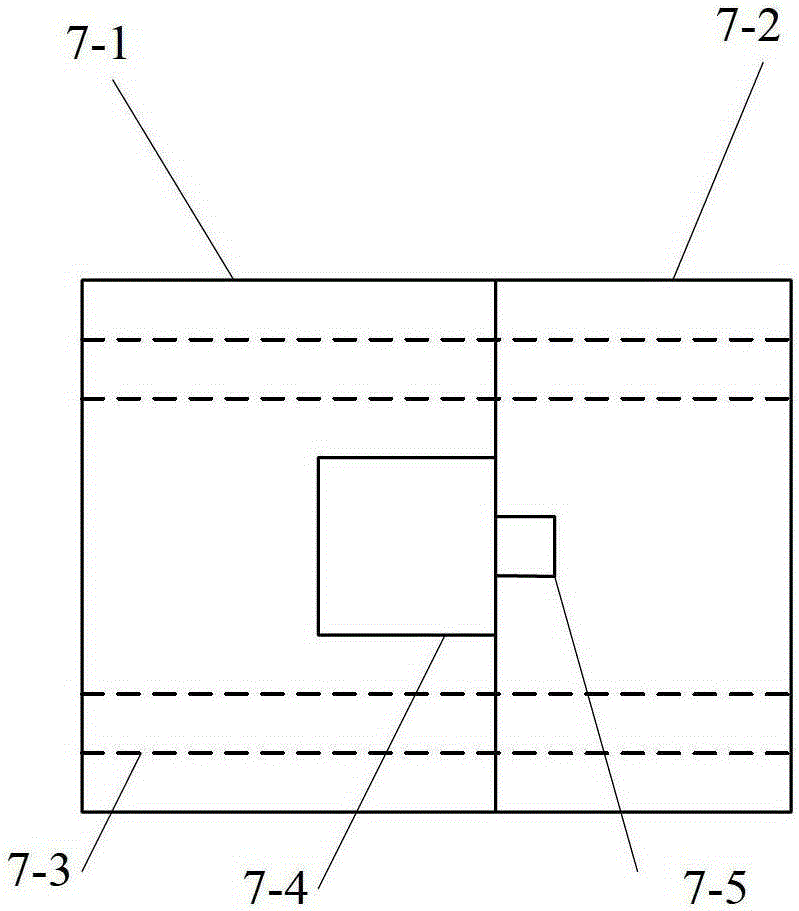

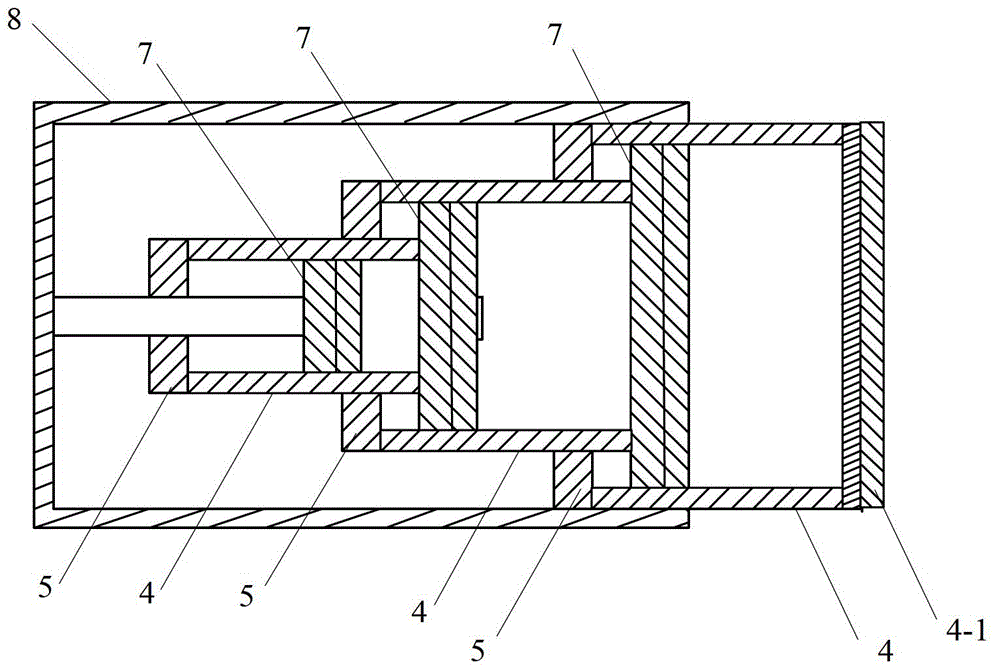

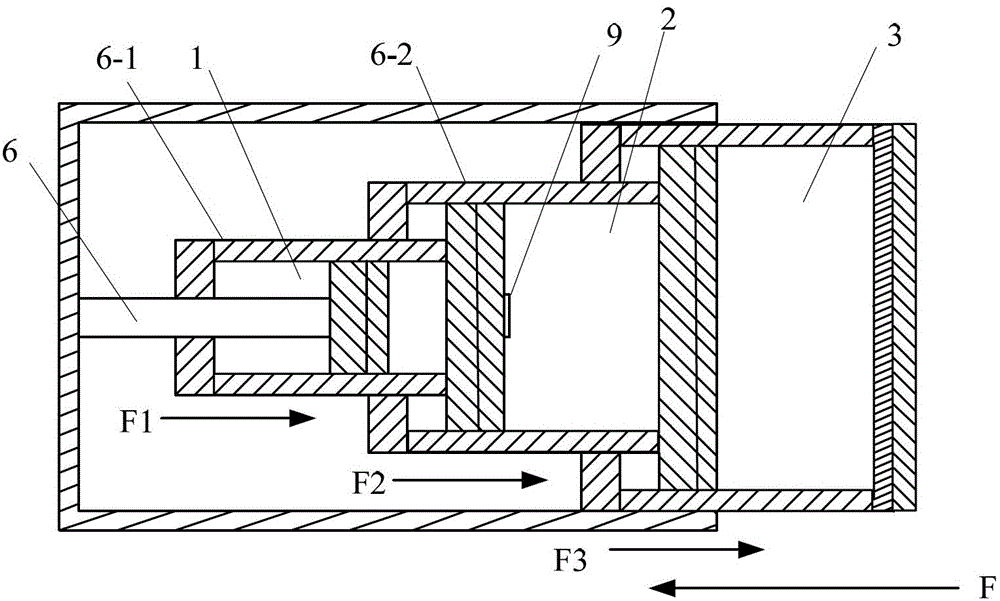

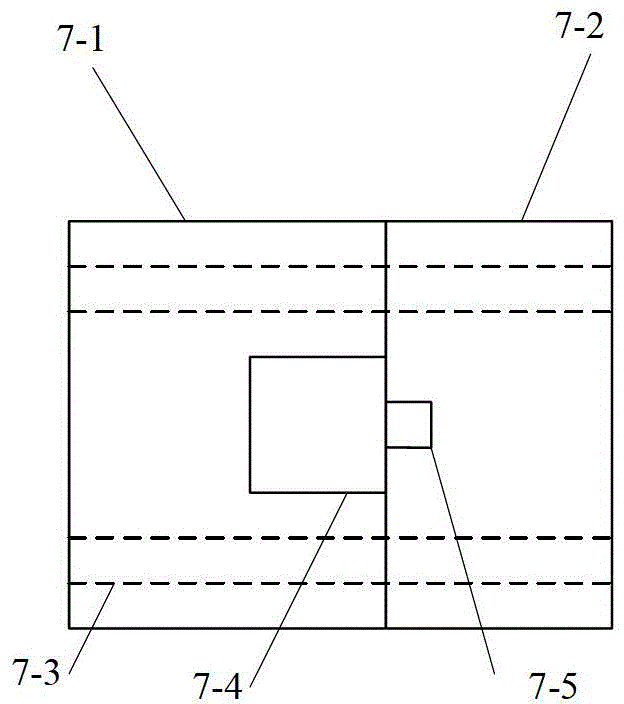

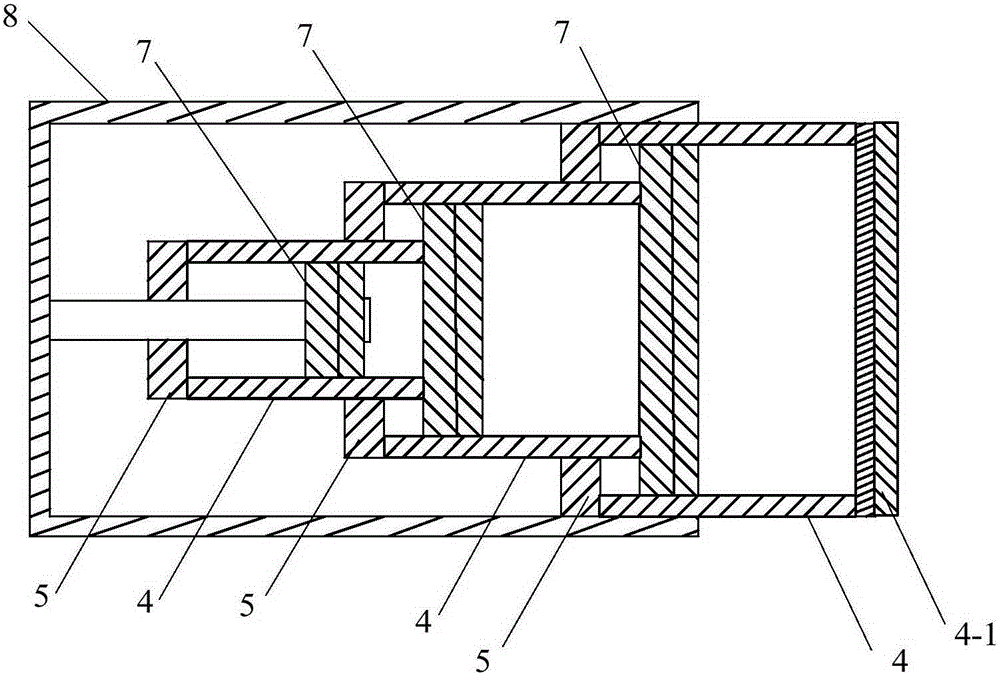

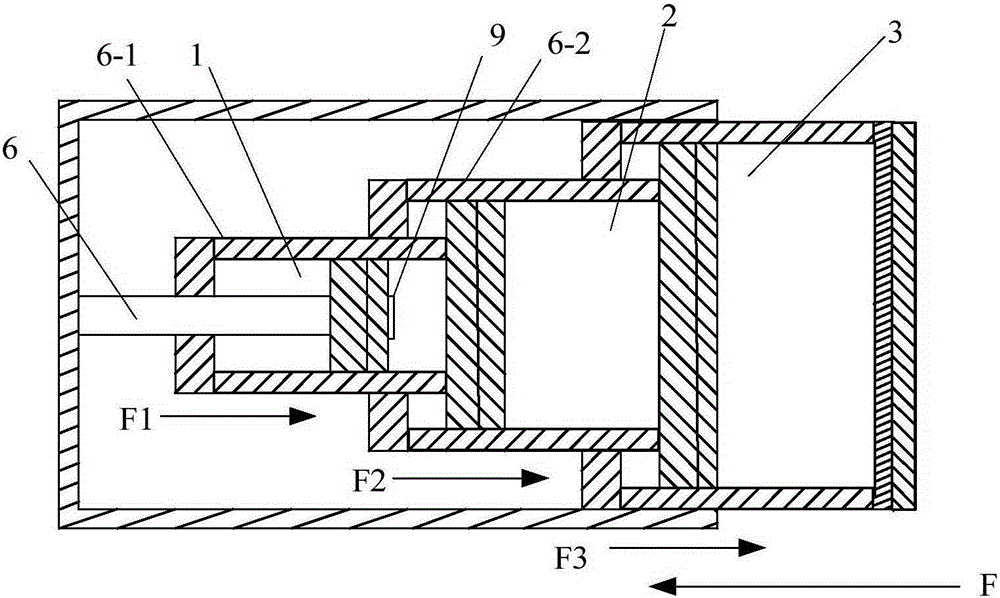

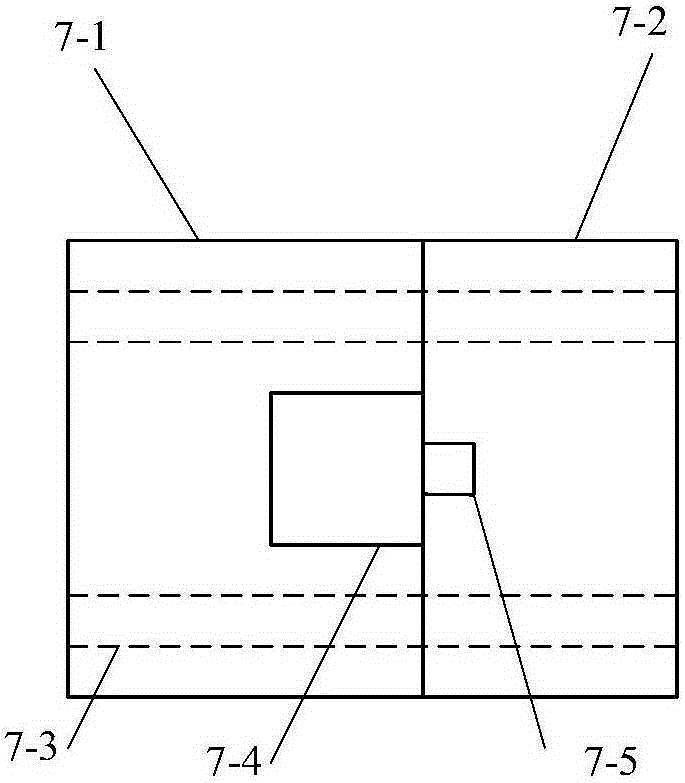

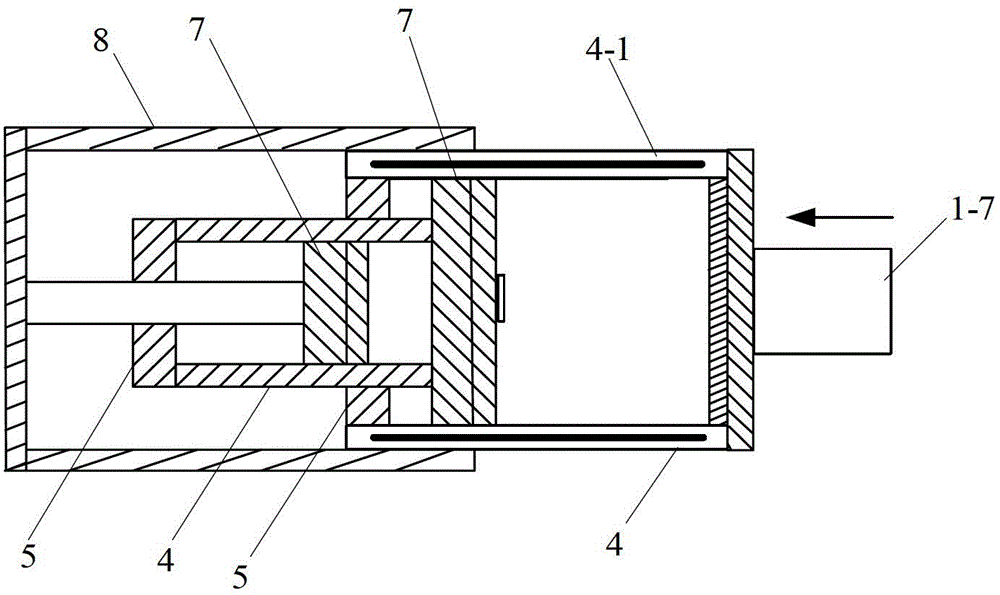

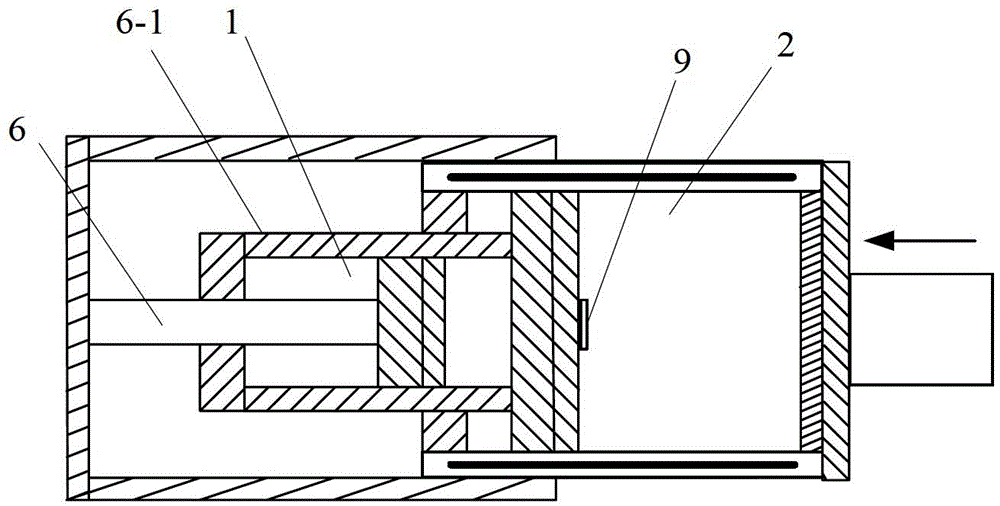

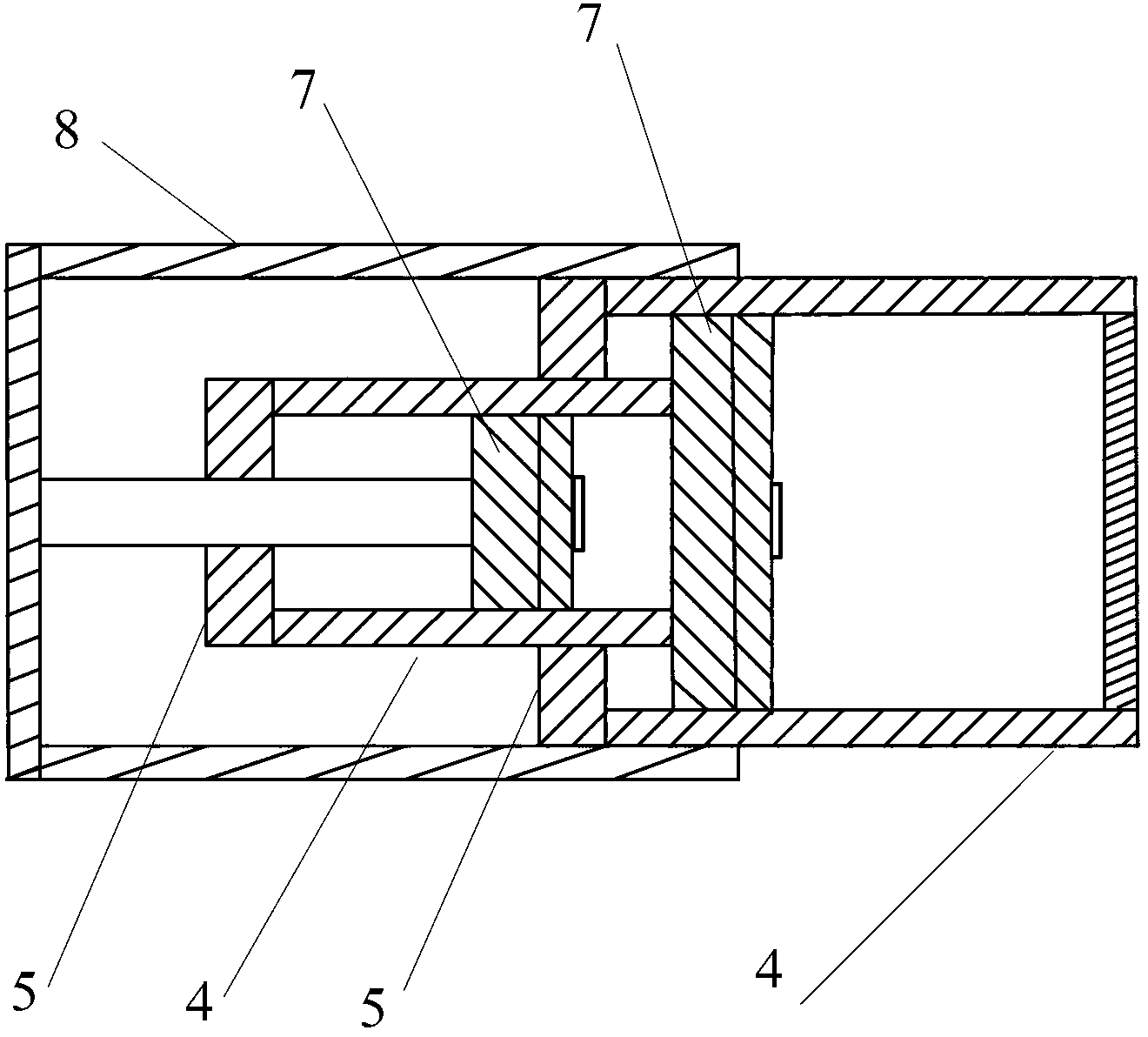

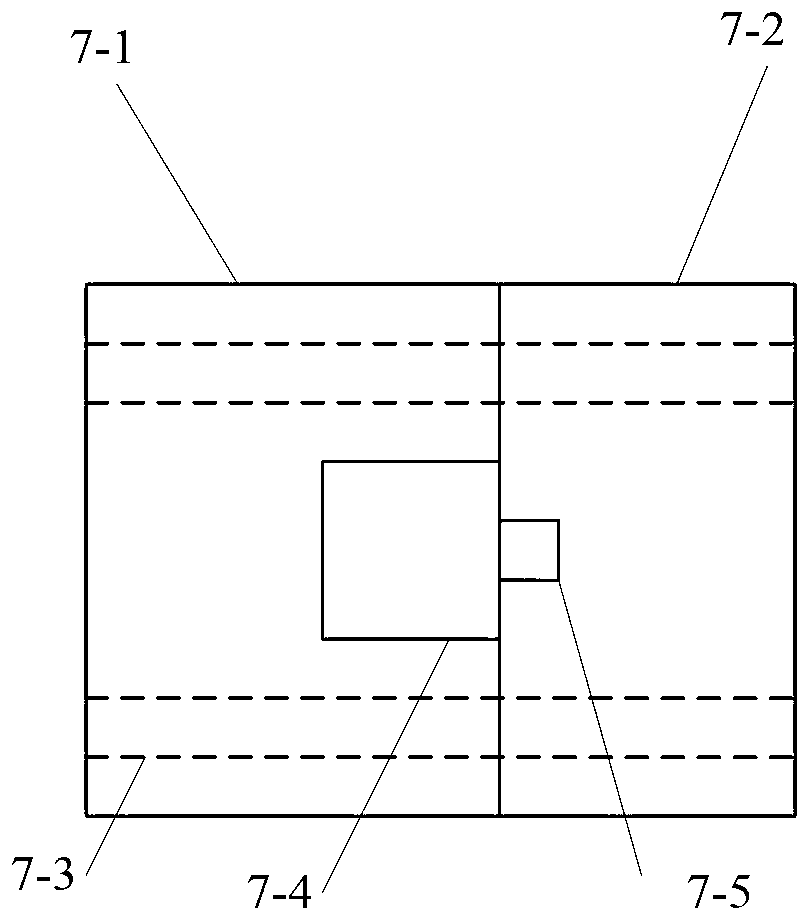

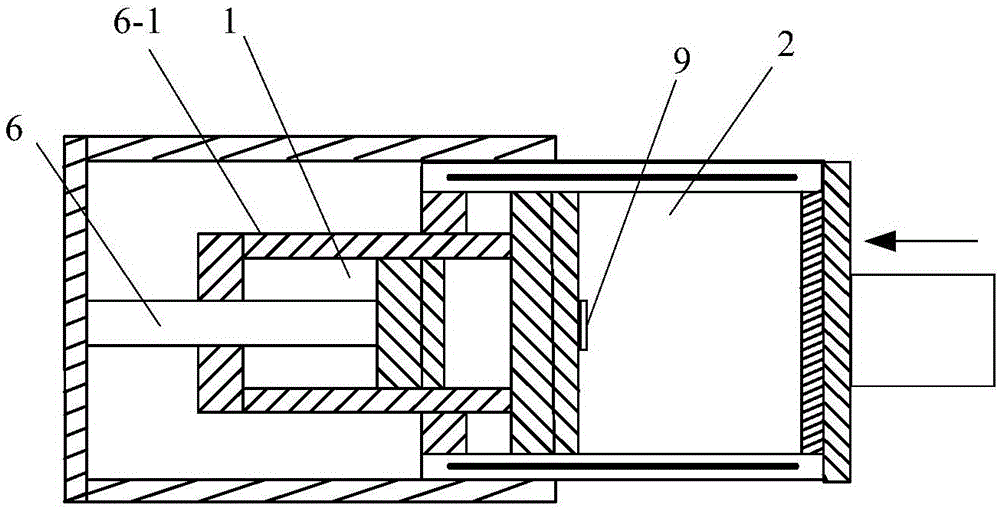

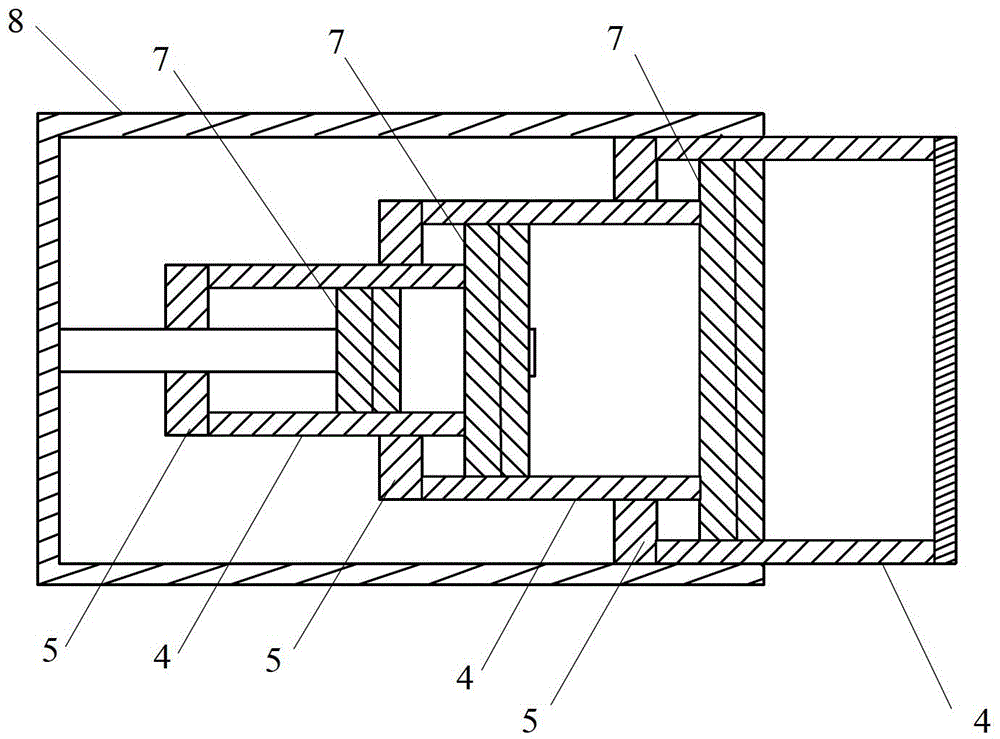

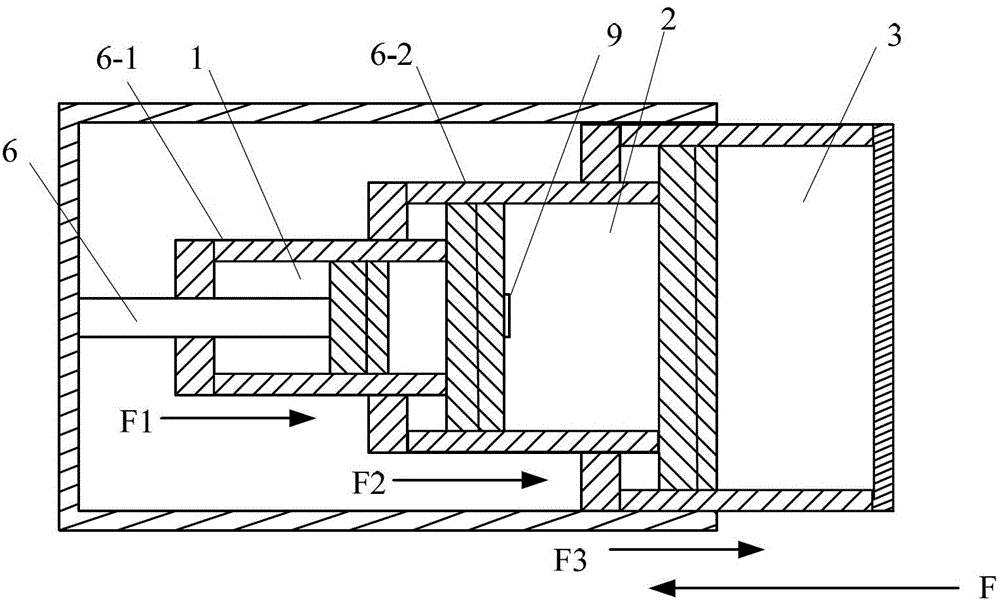

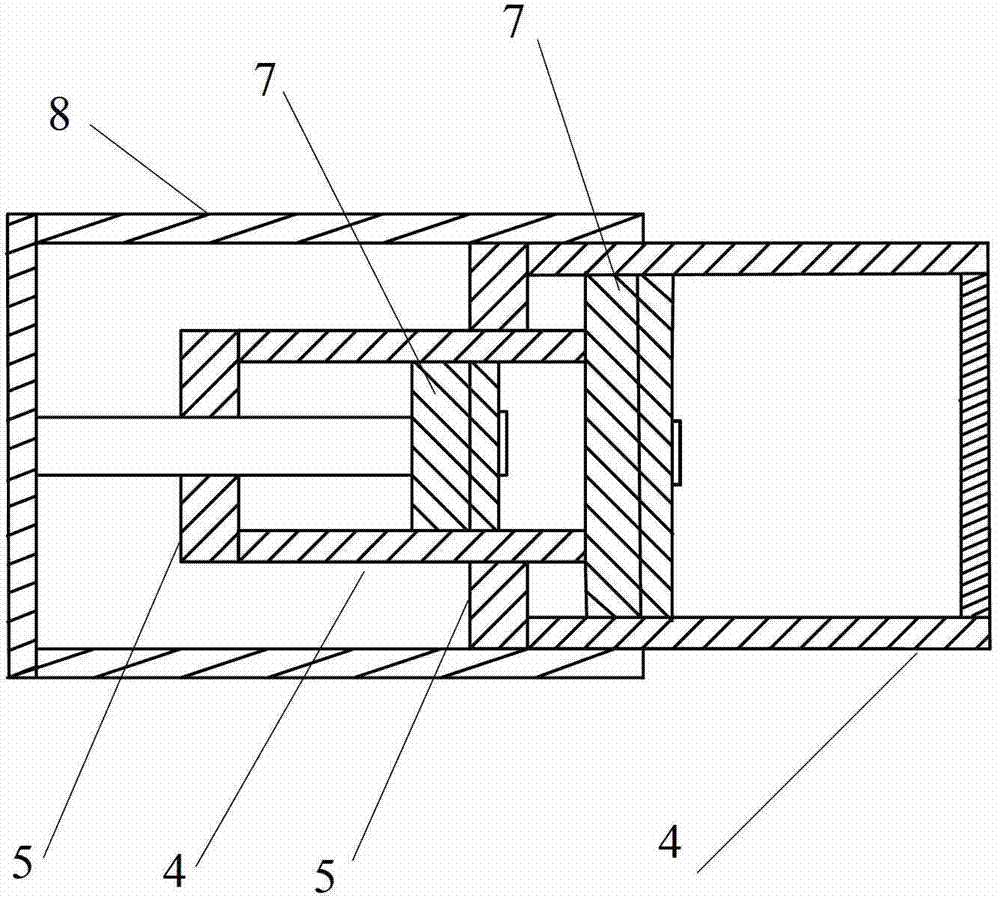

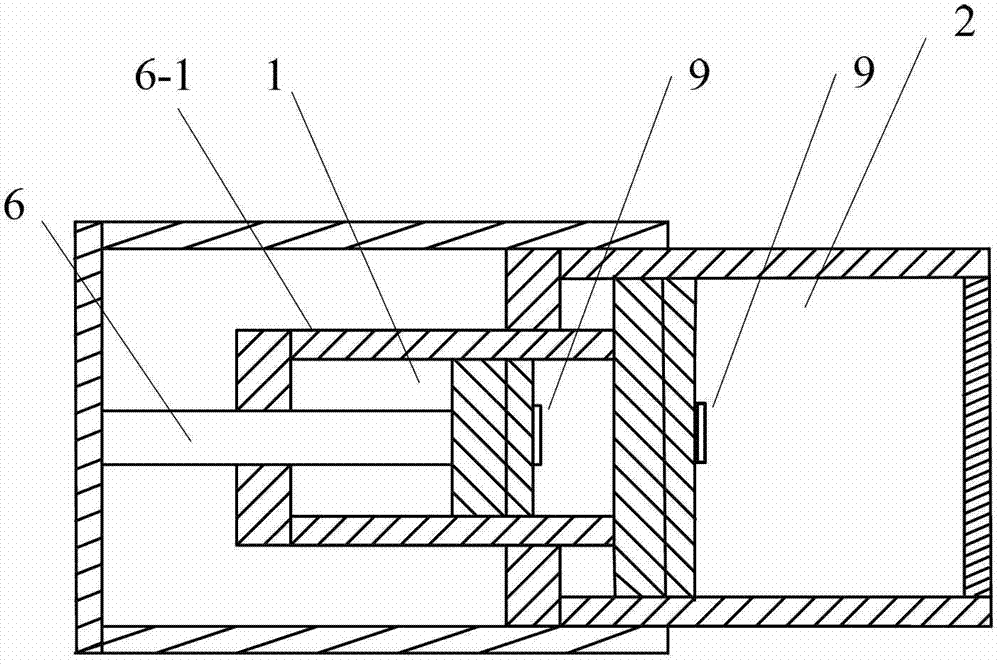

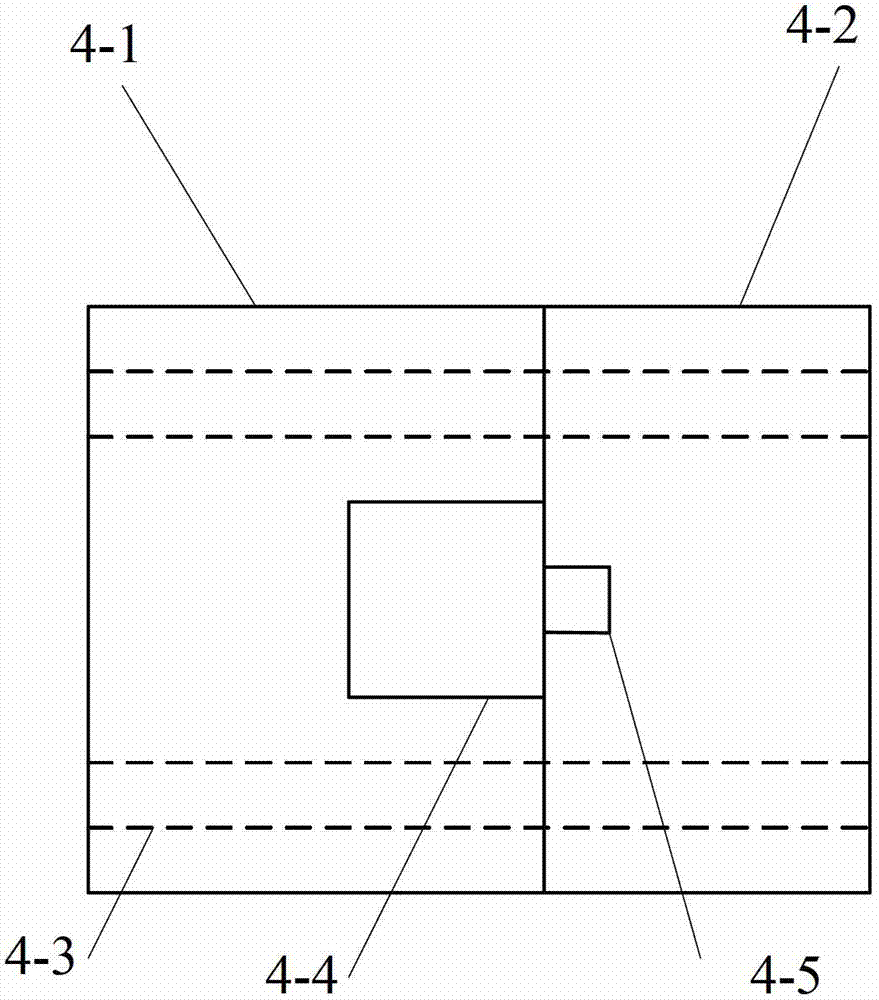

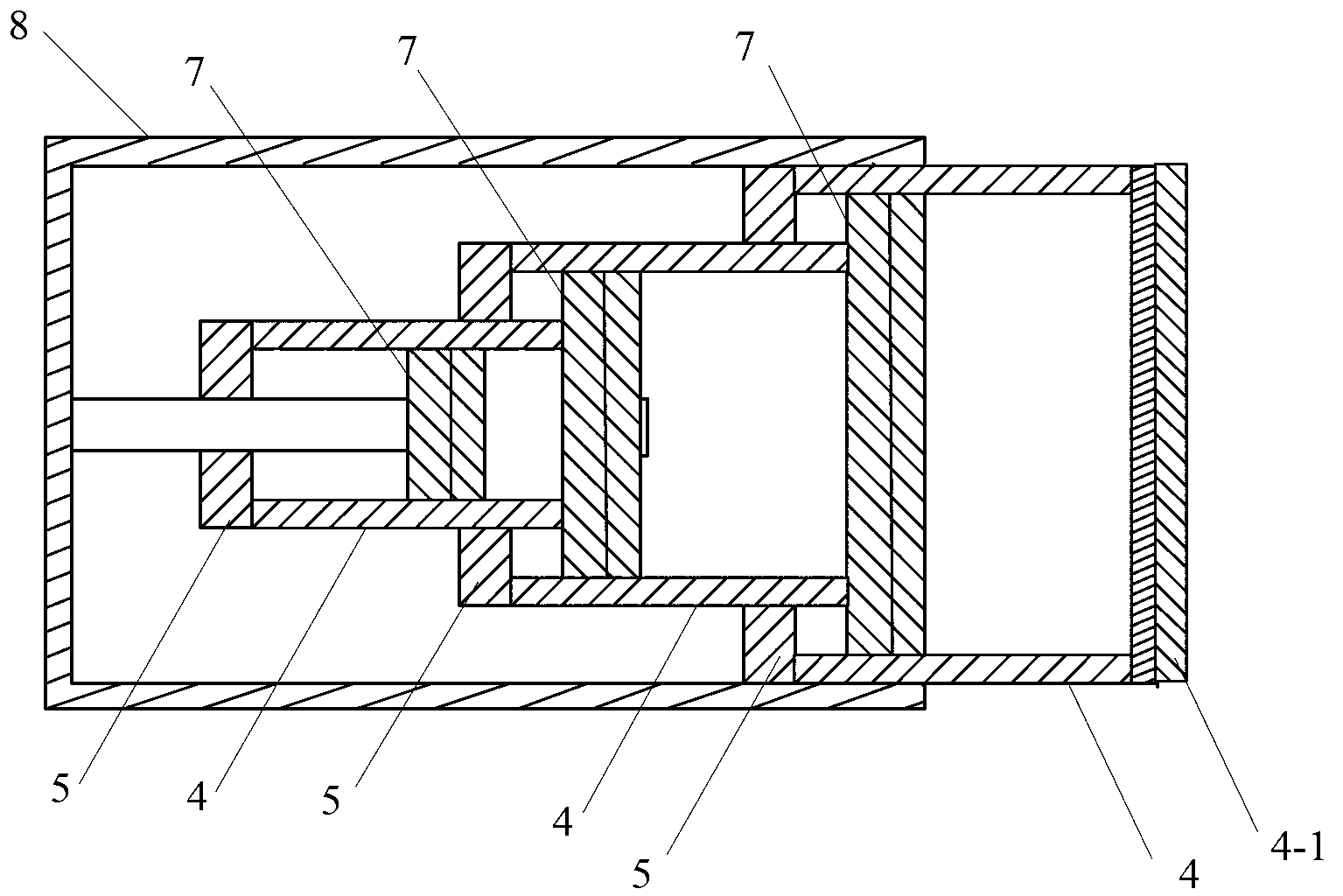

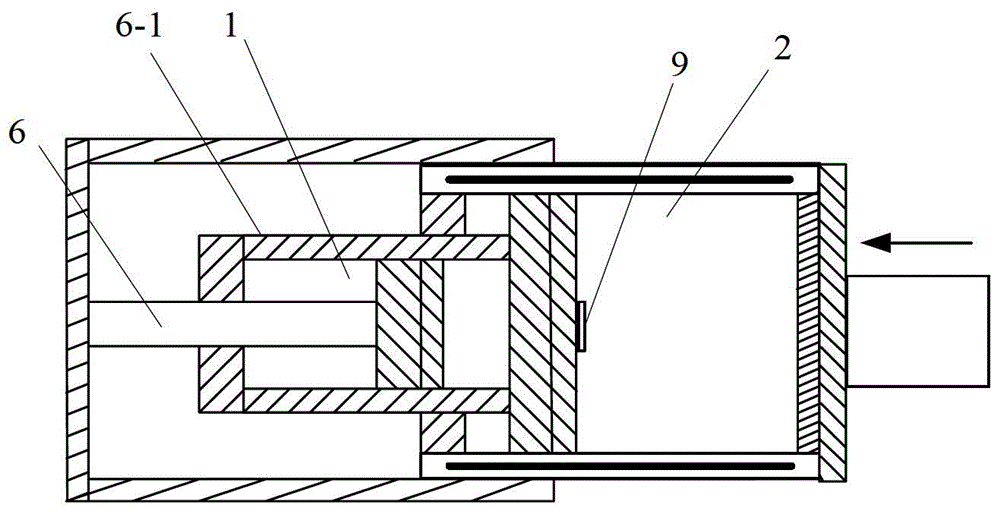

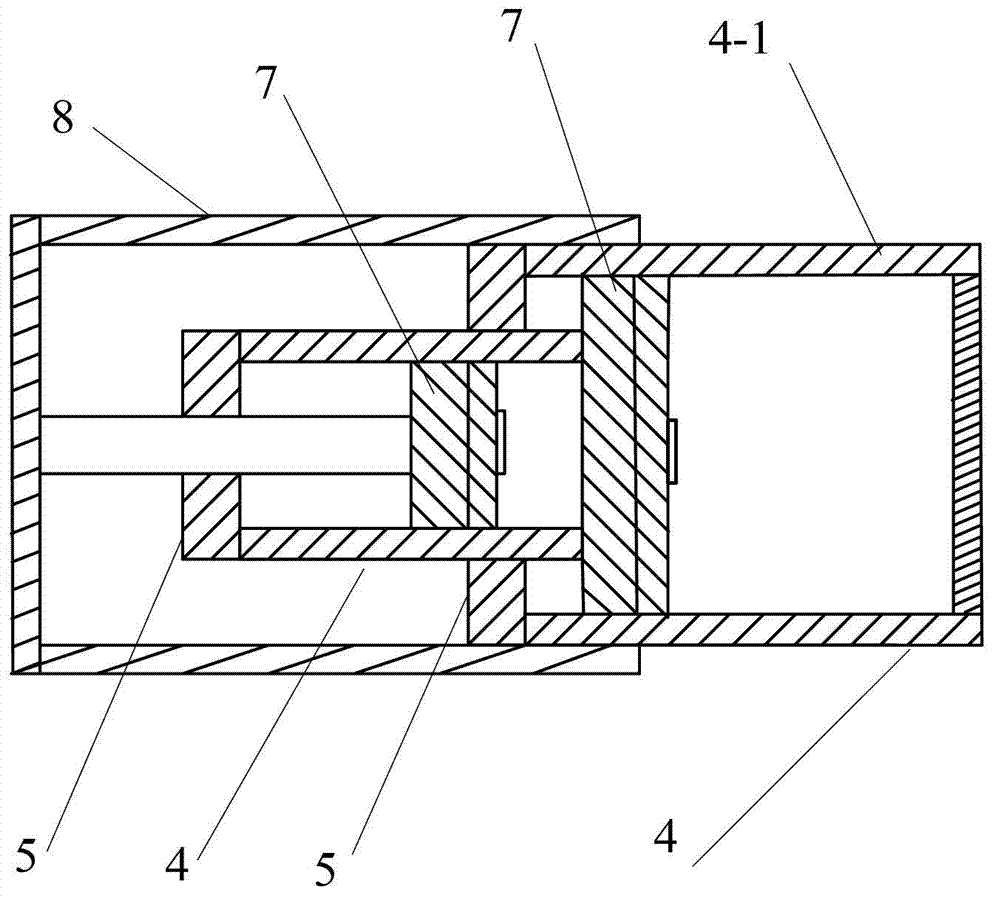

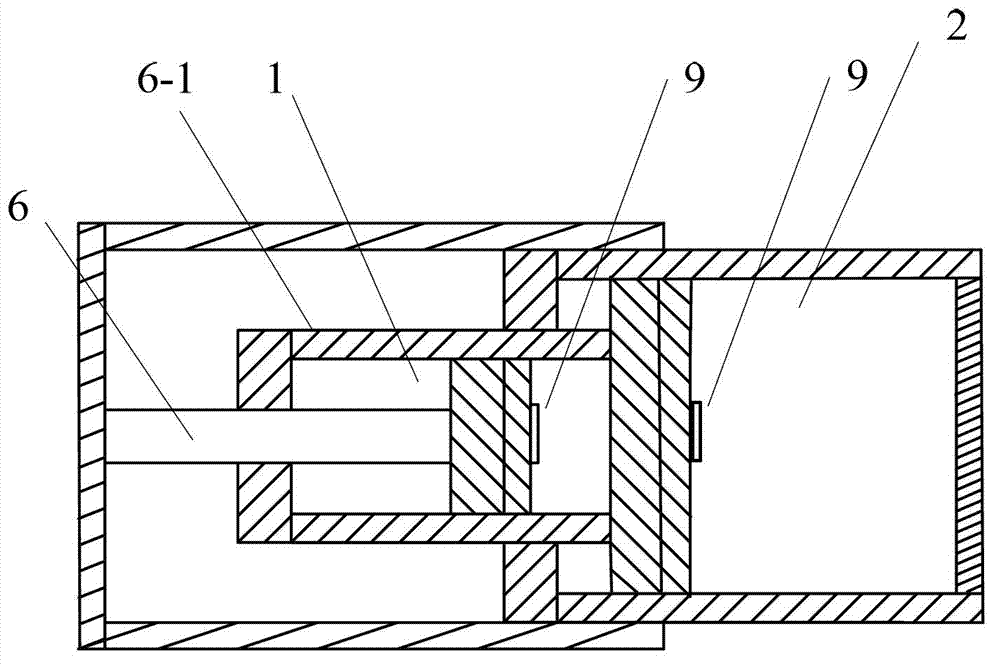

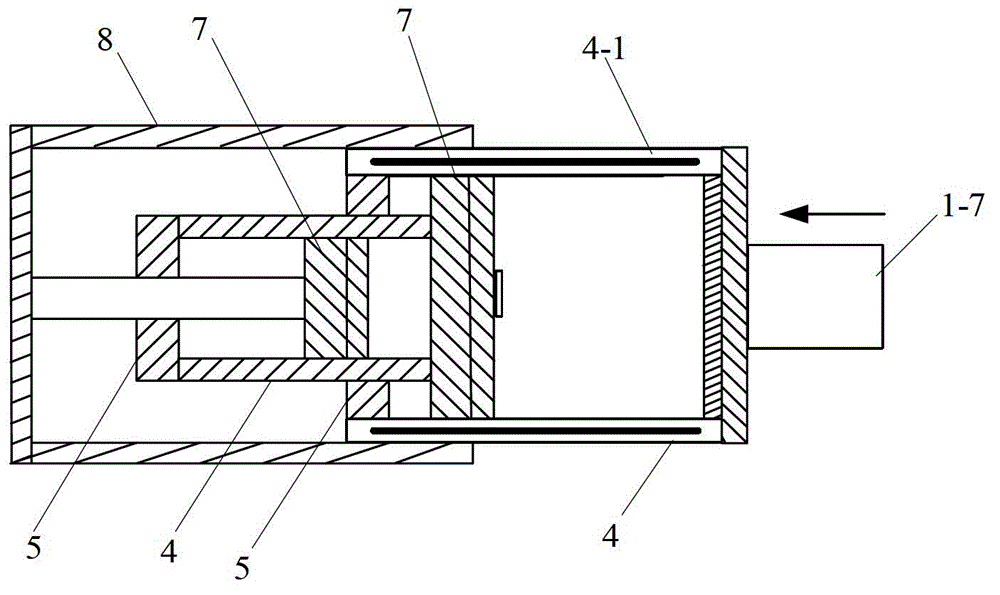

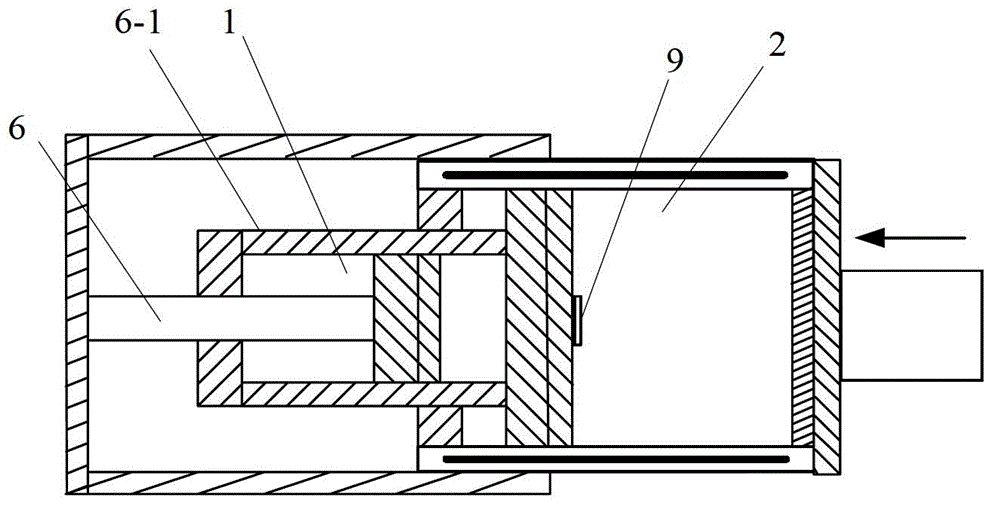

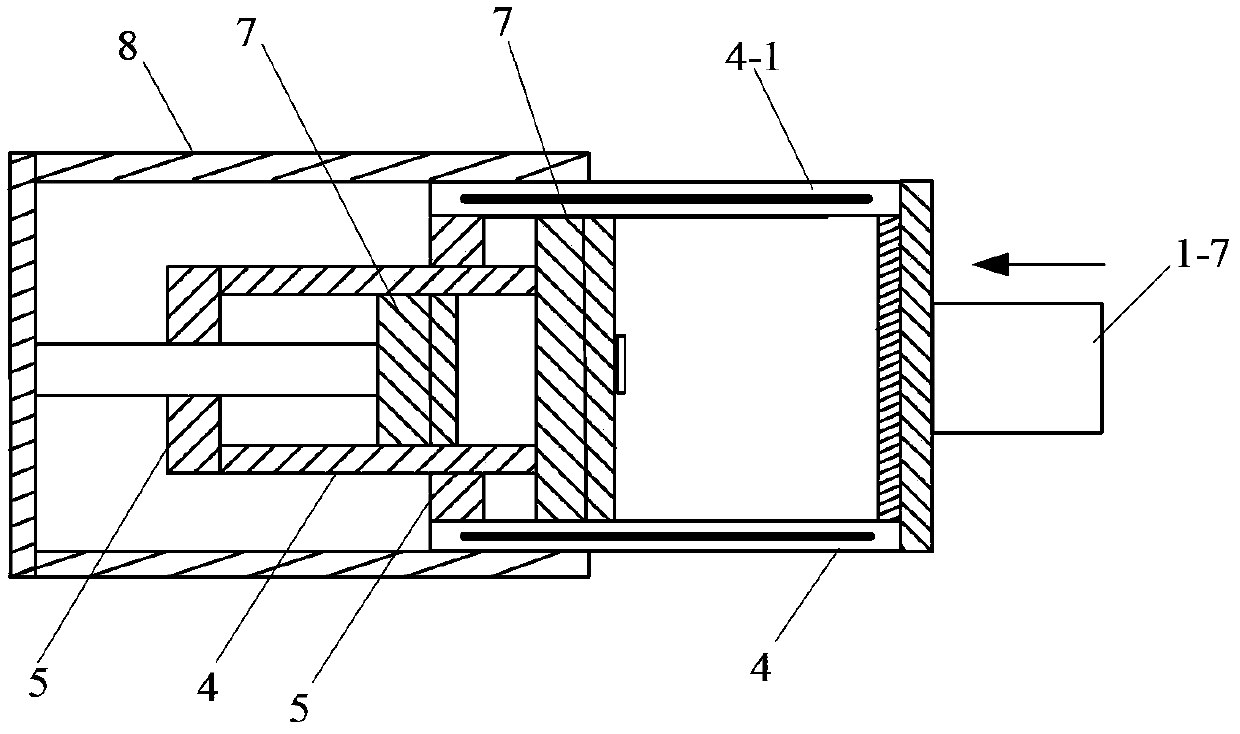

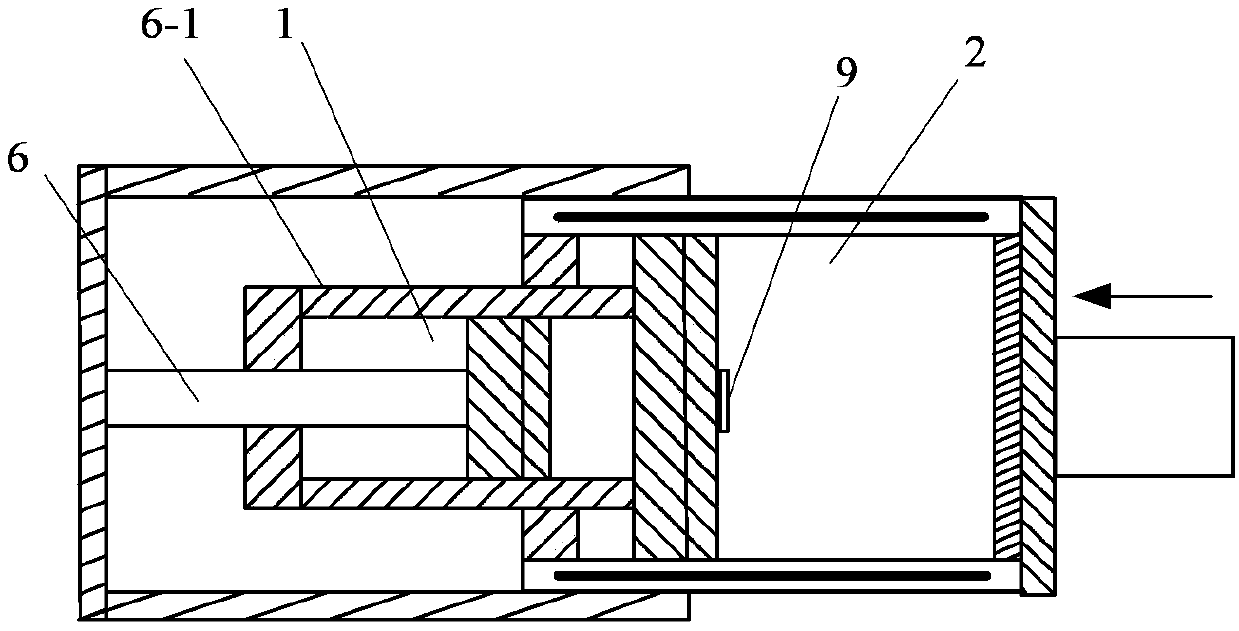

The invention relates to a three-level buffer suitable for achieving uniform buffering at all levels. The three-level buffer comprises a first-level buffer, a middle-level buffer and a last-level buffer, and is characterized in that each buffer comprises a cylindrical cylinder, wherein a cylinder cover is sealed at the opening end of the cylinder, a piston rod is movably matched with a through hole of the cylinder cover in a sealing manner, and a piston body component is arranged at the right end of the piston rod, suitable for performing piston motion in the cylinder and movably matched with the inner wall of the cylinder in a sealing manner; the cylinder of the first-level buffer forms the piston rod of the middle-level buffer, and the cylinder of the middle-level buffer forms the piston rod of the last-level buffer; a pressure sensor used for detecting medium pressure is arranged on the right end surface of the piston body component of the first-level buffer; and the piston body component of each buffer is suitable for adjusting a medium back-and-forth flow of the corresponding cylinder according to the medium pressure detected by each pressure sensor during piston motion, so that the piston motion speed can be controlled.

Owner:GUANGDONG INST OF ARTS & SCI

Three-level buffer working method suitable for adjusting all levels of buffering sequences

InactiveCN103291826AExtend your lifeControl movement speedSpringsShock absorbersTraffic capacityThree level

The invention relates to a three-level buffer working method. A three-level buffer is composed of a leading-level buffer, a middle-level buffer and a tail-level buffer. The leading-level buffer, the middle-level buffer and the tail-level buffer respectively comprise a cylinder which is in the shape of a column. Each cylinder is filled with buffering media. A cylinder cover is arranged at the opened end of the cylinder and seals an opening. A center through hole which extends axially is formed at the central axis of the cylinder cover. A piston rod penetrates through the center through hole and a piston body assembly is arranged at the top end of the piston rod, suitable for carrying out piston motion in the cylinder and matched with the inner wall of the cylinder in a movable and sealed mode. The cylinder of the leading-level buffer forms a piston rod of the middle-level buffer. The cylinder body of the middle-level buffer forms a piston rod of the tail-level buffer. A pressure sensor for detecting pressure of the media is arranged on the right end face of the piston body assembly of the leading-level buffer. When the piston body assemblies of all levels of the buffers perform piston motion, media reciprocating flow in corresponding cylinders is adjusted according to the media pressure detected by the pressure sensor so as to control speed of the piston motion.

Owner:苏州胤宗智能科技有限公司

Three-stage buffer with piston movement adjusted by processor according to impact pressure

InactiveCN105240436AExtend your lifeControl movement speedSpringsLiquid based dampersThree stageIntermediate stage

The invention relates to a three-stage buffer with piston movement adjusted by a processor according to impact pressure. The three-stage buffer is composed of a front-stage buffer body, a middle-stage buffer body and a tail-stage buffer body. The buffer bodies each comprise a cylindrical cylinder body filled with a buffer medium, cylinder covers are arranged at the opening ends of the cylinder bodies in a sealed manner, piston rods are in sealed movable fit with center through holes of the cylinder covers, and piston body assemblies are arranged at the right ends of the piston rods, are suitable for conducting piston movement in the cylinder bodies and are in movable sealed fit with the inner walls of the cylinder bodies. The cylinder body of the front-stage buffer body serves as the piston rod of the middle-stage buffer body and the cylinder body of the middle-stage buffer body serves as the piston rod of the tail-stage buffer body. A pressure sensor used for detecting the pressure of the medium is arranged on the right end face of the piston body assembly of the middle-stage buffer body. The piston body assemblies of all the buffer bodies are suitable for adjusting the reciprocating flow of the medium in the corresponding cylinder bodies in the piston movement process according to the medium pressure detected by the pressure sensor, so that the moving speeds of pistons are controlled.

Owner:蒋超

Two-stage buffer

InactiveCN104747645AControl work speedReduce work speedSpringsSprings/dampers design characteristicsBody shapeEngineering

Owner:SUZHOU TANGSHI MACHINERY MFG

Working method of full-automatic brickmaking system

The invention relates to a working method of a full-automatic brickmaking system. The full-automatic brickmaking system comprises a hydraulic forming machine used for pressing green bricks, an automatic feeder used for hanging and conveying a steam-curing car to a stacking area, a positioner used for limiting the steam-curing car to the stacking area, and a robot used for stacking the green bricks on the steam-curing car. The positioner comprises a support arm and a cylinder used for supporting or putting down the support arm. The positioner is fixed on the upper end face of a slider in sliding fit with a guide rail. A cushioning device is arranged at the left end of the guide rail and used for cushioning slider impact force generated when the steam-curing car impacts on the positioner, and the right end face of the cushioning device and the left end face of the slider are in close contact. The working method includes that when the steam-curing car impacts on the supported support arm, the cushioning device cushions the slider impact force so as to relieve pressure on the cylinder due to impact of the steam-curing car.

Owner:临沭县济才人力资源服务有限公司

Two-level buffer suitable for controlling buffering sequence step by step

InactiveCN103352953AExtend your lifeControl movement speedSpringsLiquid based dampersEngineeringCylinder block

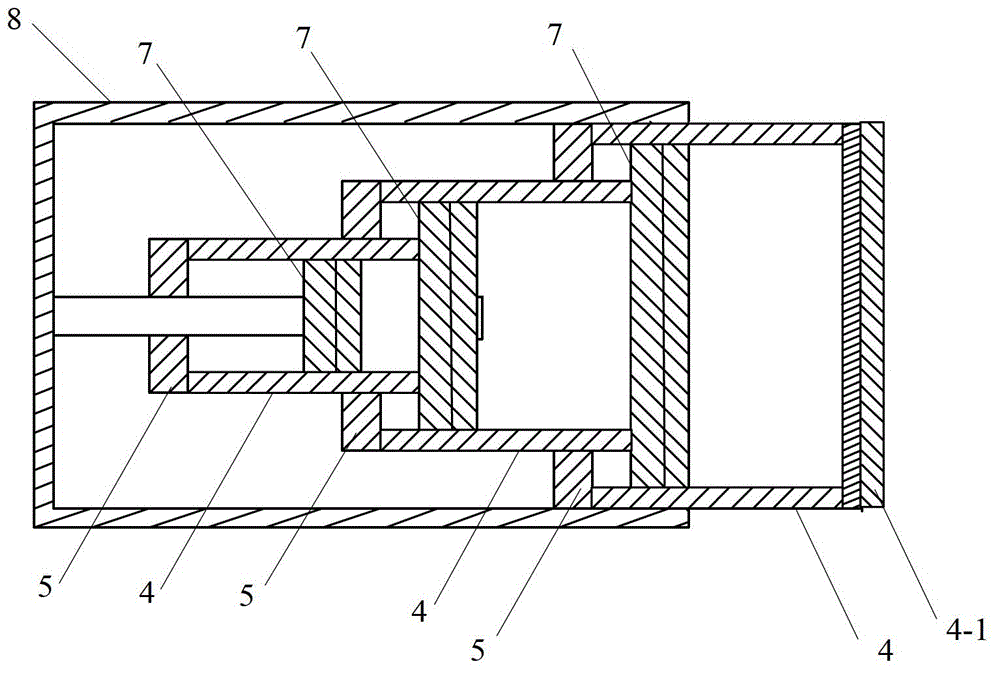

The invention relates to a two-level buffer suitable for controlling a buffering sequence step by step. The two-level buffer comprises a first-level buffer and a last-level buffer, and is characterized in that each buffer comprises a cylindrical cylinder, wherein a cylinder cover is arranged at the opening end of the cylinder in a sealing manner, a piston rod is movably matched with a through hole of the cylinder cover in a sealing manner, and a piston body component is arranged at the right end of the piston rod, suitable for performing piston motion in the cylinder and movably matched with the inner wall of the cylinder in a sealing manner; the cylinder of the first-level buffer forms the piston rod of the last-level buffer; a pressure sensor used for detecting medium pressure is arranged on the right end surface of the piston body component of each of the first-level buffer and the last-level buffer; and the piston body component of each buffer is suitable for adjusting a medium back-and-forth flow of the corresponding cylinder according to the medium pressure detected by each pressure sensor during piston motion, so that the piston motion speed can be controlled.

Owner:江阴泛函电气自动化有限公司

A working method of a temperature-protected two-stage buffer

ActiveCN103291805BControl work speedReduce work speedSpringsLiquid based dampersWorking temperatureMechanical engineering

Owner:苏州卫优知识产权运营有限公司

The working method of the intelligent code stomping device for hollow blocks and bricks

The invention relates to a working method of an intelligent stacker crane used for raw brick stack. The intelligent stacker crane comprises an automatic feeding machine, a positioner, and a robot used for stacking to a steam-curing car, wherein the positioner comprises a support arm used for supporting up or laying down the cylinder of a support arm; the positioner is fixed on an upper end surface of a slide block; the slide block is in sliding fit with a guide rail body, a buffer device is arranged at the left end of the guide rail body, and the buffer device is used for buffering slide block impact caused when the steam-curing car impacts the positioner; the working method of the intelligent stacker crane comprises the followings: the buffer device buffers the slide block impact when the steam-curing car impacts the support arm supported up, so as to relieve pressure received by the cylinder and caused by the impact of the steam-curing car. According to the invention, due to the use of the buffer device, the impact from the steam-curing car to the cylinder can be effectively relieved when the steam-curing car impacts the support arm supported up, and the service life of the cylinder is effectively prolonged.

Owner:临沭县济才人力资源服务有限公司

Three-stage buffer with piston movement adjusted by processor according to impact pressure

InactiveCN105240438AExtend your lifeControl movement speedSpringsLiquid based dampersThree stageIntermediate stage

Owner:蒋超

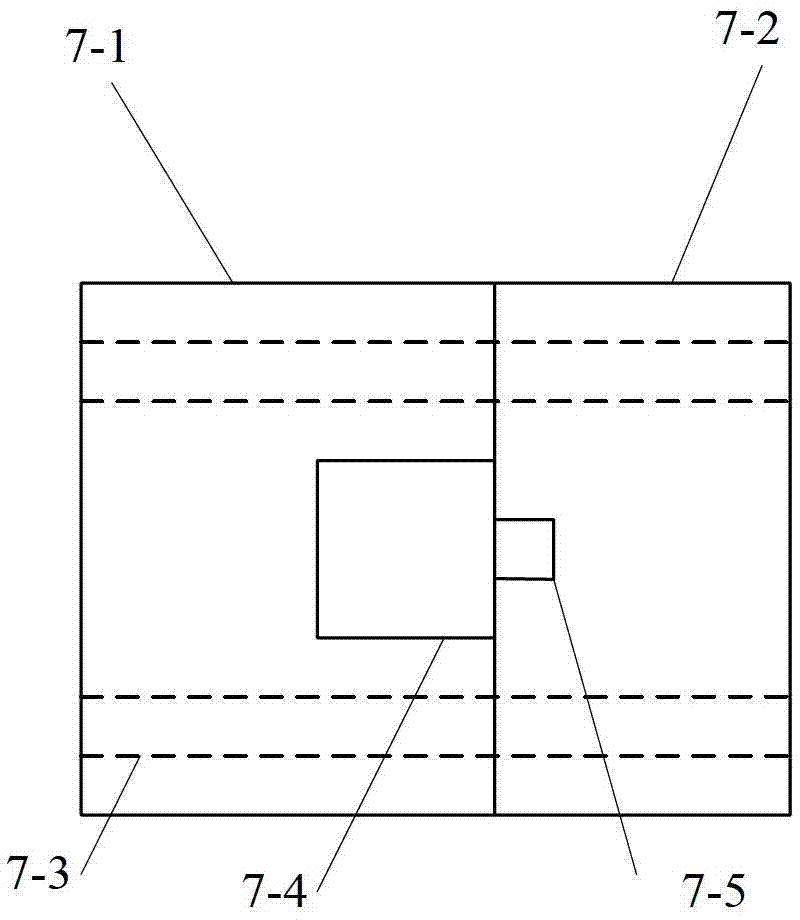

Hollow block palletizing device

The invention relates to a hollow block stacking device which comprises an automatic feeder and a positioner and a robot used for stacking on steam-curing car. The positioner which is fixed on the upper end face of a slider comprises a supporting arm and a cylinder used for supporting or putting down the support arm, the slider is in sliding fit with a guide rail, a cushioning device is arranged at the left end of the guide rail and used for cushioning slider impact force generated when the steam-curing car impacts on the positioner. A working method of the hollow block stacking device includes that when the steam-curing car impacts on the supported support arm, the cushioning device cushions the slider impact force so as to relieve pressure on the cylinder due to impact of the steam-curing car. The cushioning device cushions the impact force of the steam-curing car on the cylinder when the steam-curing car impacts on the supported support arm, so that the impact force on the cylinder can be relieved effectively, and service life of the cylinder is prolonged effectively.

Owner:临沭县济才人力资源服务有限公司

Three-stage buffer suitable for controlling buffer sequence step by step

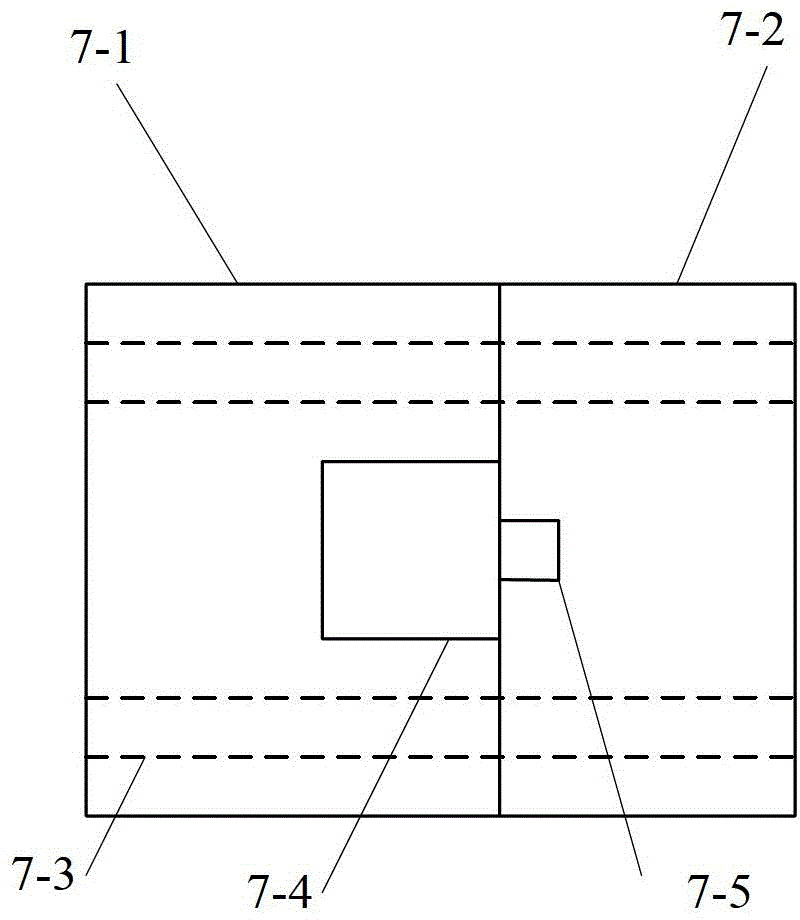

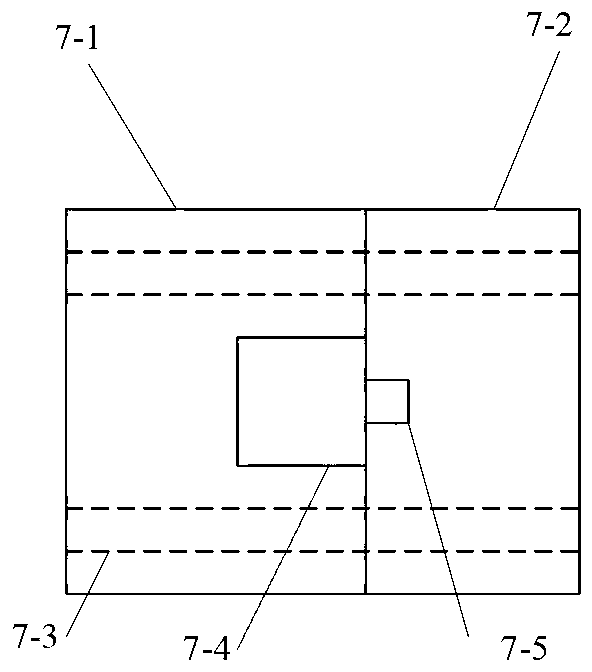

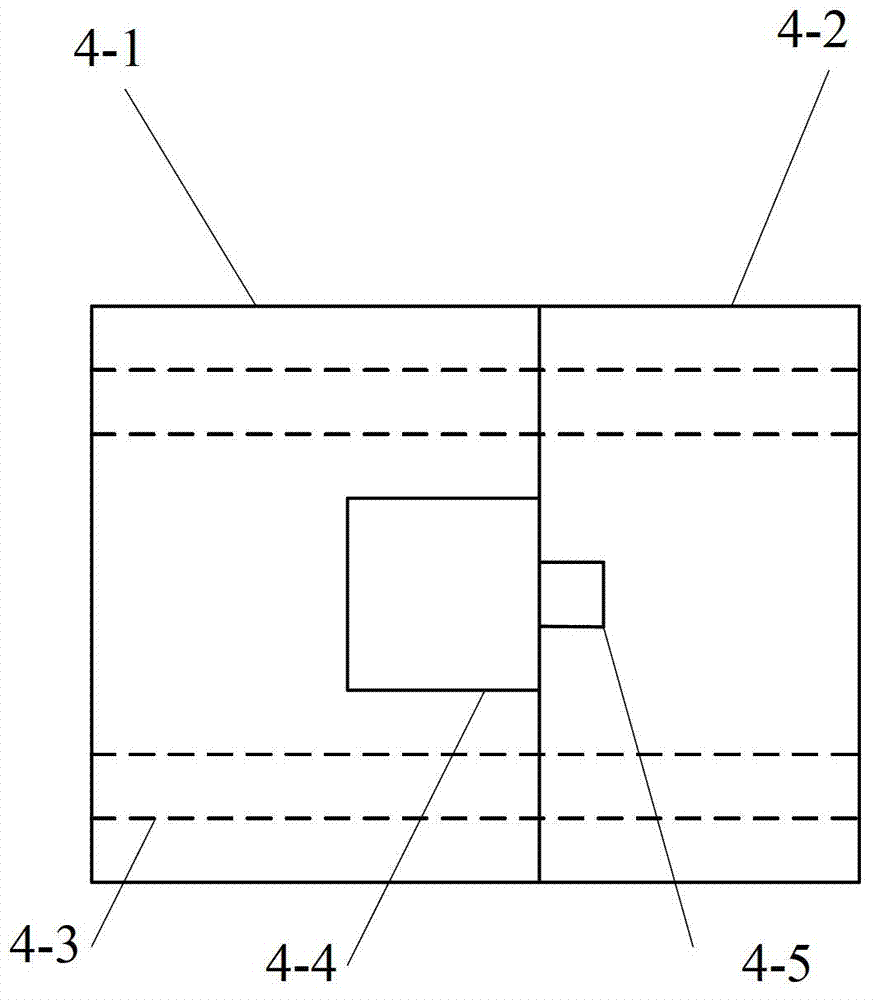

The invention relates to a three-stage buffer suitable for controlling the buffer sequence step by step. The three-stage buffer comprises a first-stage buffer, an intermediate-stage buffer and a last-stage buffer; the first-stage buffer, the intermediate-stage buffer and the last-stage buffer respectively comprise a cylinder body which is in a cylindrical shape and is used for filling buffer medium, an opening end of the cylinder body is provided with a cylinder cover in a sealing way, a center through hole of the cylinder cover is internally and movably matched with a piston rod in the sealing way, the right end of the piston rod is provided with a piston body assembly, the piston body assembly is suitable for doing piston motion in the cylinder body, and the piston body assembly is in movable sealing match with the inner wall of the cylinder body; the piston rod of the intermediate-stage buffer is formed by the cylinder body of the first-stage buffer, and the piston rod of the last-stage buffer is formed by the cylinder body of the intermediate-stage buffer; the right end surface of the piston body assembly of the first-stage buffer is provided with a pressure sensor which is used for detecting medium pressure; and the piston body assembly of each buffer is suitable for regulating the back-and-forth flow of the medium in the corresponding cylinder body according to the medium pressure detected by the pressure sensor when the piston body assembly does the piston motion, and thus the motion speed of each piston can be controlled.

Owner:启东市罗源光伏设备有限公司

A working method of an automatic feeder in a fully automatic hydraulic forming machine

ActiveCN103395116BShock mitigationExtend your lifeCeramic shaping apparatusStacking articlesBrickEngineering

The invention relates to a working method of an automatic feeding machine in a full-automatic hydraulic forming machine for hollow blocks and bricks. The automatic feeding machine comprises a feeding car used for hanging and conveying a steam-curing car to a stacking area and a positioner used for limiting the steam-curing car in the stacking area. The positioner comprises a support arm and a cylinder used for supporting or putting down the support arm. The positioner is fixed on the upper end face of a slider in sliding fit with a guide rail, and a cushioning device is arranged at the left end of the slide rail and used for cushioning slider impact force produced when the steam-curing car impacts on the positioner. The working method of the automatic feeder includes that when the steam-curing car impacts on the supported support arm, the cushioning device cushions the slider impact force so as to relieve pressure on the cylinder due to impact of the steam-curing car. The cushioning device cushions the impact force of the steam-curing car on the cylinder when the steam-curing car impacts on the supported support arm, so that the impact force on the cylinder can be relieved effectively, and service life of the cylinder is prolonged effectively.

Owner:临沭县济才人力资源服务有限公司

Intelligent code stamping device for hollow blocks and bricks

ActiveCN103398128BShock mitigationExtend your lifeSpringsAuxillary shaping apparatusBrickMechanical engineering

Owner:临沭县济才人力资源服务有限公司

Three-level buffer suitable for achieving even buffering of each level

ActiveCN103291806AExtended buffer lifeWide range of applicationsSpringsLiquid based dampersThree levelPressure sensor

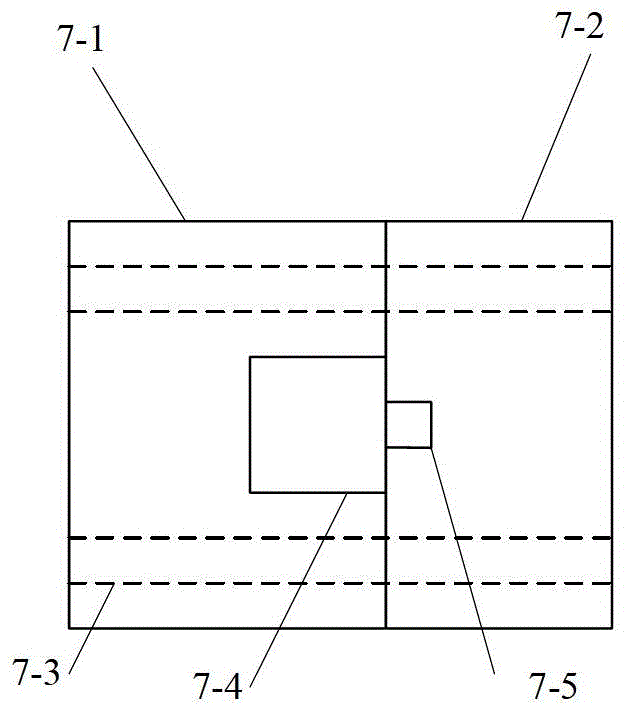

The invention relates to a three-level buffer suitable for achieving even buffering of each level. The three-level buffer comprises a primary level buffer, a middle level buffer and a last level buffer. Each level of buffer comprises a cylinder body of a cylindrical shape, wherein a cylinder cover is arranged at the opening end of each cylinder body in a sealing mode, a piston rod is arranged in a center through hole of each cylinder cover in a sealing movable and matching mode, and the right end of each piston rod is provided with a piston body component which is suitable for conducting piston motion in each cylinder body and is matched with the inner wall of each cylinder body in a movable and sealing mode. The cylinder body of the primary level buffer forms the piston rod of the middle level buffer, the cylinder body of the middle level buffer forms the piston rod of the last level buffer, the right end face of the piston body component of the primary level buffer is provided with a pressure sensor used for detecting medium pressure, and the piston body component of each level of buffer is suitable for adjusting the back-and-forth flow of medium in a corresponding cylinder body and controlling the speed of the piston motion according to the medium pressure detected by the pressure sensor when the piston motion is conducted.

Owner:苏州威斯道智能科技有限公司

Working method of hollow block and brick automatic hydraulic forming machine

The invention relate to a working method of a full-automatic hydraulic forming machine for bricks. The full-automatic hydraulic forming machine comprises an automatic feeder and a positioner. The positioner comprises a support arm and a cylinder used for supporting or putting down the support arm. The positioner is fixed on the upper end face of a slider in slide fit with a guide rail. A cushioning device is arranged at the left end of the guide rail and used for cushioning slider impact force generated when a steam-curing car impacts on the positioner. The right end face of the cushioning device is in close contact with the left end face of the slider. The working method specifically includes when the steam-curing car impacts on the supported support arm, the cushioning device cushions the slider impact force so as to relieve pressure on the cylinder due to impact of the steam-curing car. When the steam-curing car impacts on the supported support arm, the impact force of the steam-curing car on the cylinder is cushioned, so that the impact force on the cylinder can be relieved effectively, and service life of the cylinder is prolonged effectively.

Owner:临沭县济才人力资源服务有限公司

Two-stage buffer capable of controlling buffering sequence stage by stage

InactiveCN103307178AExtend your lifeControl movement speedSpringsSolid based dampersEngineeringTraffic flow

The invention relates to a two-stage buffer capable of controlling a buffering sequence stage by stage. The buffer comprises a first stage buffer part and a final stage buffer part, wherein each of the first stage buffer part and the final stage buffer part comprises a columniform cylinder body; cylinder covers are arranged at open ends of the cylinder bodies in a sealing manner; a piston rod is movably matched with a center through hole of each cylinder cover in a sealing manner; piston body components are arranged at the right ends of the piston rods; the piston body components can make piston motion in the cylinder bodies, and are movably matched with inner walls of the cylinder bodies in a sealing manner; the cylinder body of the first stage buffer part forms the piston rod of the final stage buffer part; pressure sensors for detecting medium pressures are arranged on the right end surfaces of the piston body components of the first stage buffer part and the final stage buffer part; and the piston body components of both the buffer parts are can adjust the medium traffic flows in the corresponding cylinder bodies according to the medium pressures detected by the pressure sensors to control the speed of the piston motion during the piston motion.

Owner:苏州威斯道智能科技有限公司

A two-stage buffer suitable for realizing uniform buffering at all levels

InactiveCN103307176BExtend your lifeControl movement speedSpringsLiquid based dampersEngineeringCylinder block

The invention relates to a two-stage buffer capable of realizing uniform buffering of both stages. The two-stage buffer comprises a first stage buffer part and a final stage buffer part, wherein each of the first stage buffer part and the final stage buffer part comprises a columniform cylinder body; cylinder covers are arranged at open ends of the cylinder bodies in a sealing manner; a piston rod is movably matched with a center through hole of each cylinder cover; piston body components are arranged at the right ends of the piston rods; the piston body components can make piston motion in the cylinder bodies, and are movably matched with inner walls of the cylinder bodies in a sealing manner; the cylinder body of the first stage buffer part forms the piston rod of the final stage buffer part; a pressure sensor for detecting medium pressure is arranged on the right end surface of the piston body component of the first stage buffer part; and the piston body components of both the buffer parts can adjust the medium traffic flows in the corresponding cylinder bodies according to the medium pressure detected by the pressure sensor to control the speed of the piston motion during the piston motion.

Owner:苏州威斯道智能科技有限公司

A Three-Stage Buffer Suitable for Controlling the Buffering Order Gradually

The invention relates to a three-stage buffer suitable for controlling the buffer sequence step by step. The three-stage buffer comprises a first-stage buffer, an intermediate-stage buffer and a last-stage buffer; the first-stage buffer, the intermediate-stage buffer and the last-stage buffer respectively comprise a cylinder body which is in a cylindrical shape and is used for filling buffer medium, an opening end of the cylinder body is provided with a cylinder cover in a sealing way, a center through hole of the cylinder cover is internally and movably matched with a piston rod in the sealing way, the right end of the piston rod is provided with a piston body assembly, the piston body assembly is suitable for doing piston motion in the cylinder body, and the piston body assembly is in movable sealing match with the inner wall of the cylinder body; the piston rod of the intermediate-stage buffer is formed by the cylinder body of the first-stage buffer, and the piston rod of the last-stage buffer is formed by the cylinder body of the intermediate-stage buffer; the right end surface of the piston body assembly of the first-stage buffer is provided with a pressure sensor which is used for detecting medium pressure; and the piston body assembly of each buffer is suitable for regulating the back-and-forth flow of the medium in the corresponding cylinder body according to the medium pressure detected by the pressure sensor when the piston body assembly does the piston motion, and thus the motion speed of each piston can be controlled.

Owner:启东市罗源光伏设备有限公司

Three-stage buffer controlled by processor module

InactiveCN105221630AExtend your lifeControl movement speedSpringsLiquid based dampersThree stageComputer module

The invention relates to a three-stage buffer controlled by a processor module. The three-stage buffer controlled by the processor module is composed of a front-stage buffer body, a middle-stage buffer body and a tail-stage buffer body. The buffer bodies each comprise a cylindrical cylinder body filled with a buffer medium, cylinder covers are arranged at the opening ends of the cylinder bodies and used for sealing openings, and center through holes extending in the axial direction are formed in the cylinder covers along the center axes. Piston rods penetrate the center through holes. Piston body assemblies are arranged at the top ends of the piston rods and suitable for conducting piston movement in the cylinder bodies, and the piston body assemblies are in movable sealed fit with the inner walls of the cylinder bodies. The cylinder body of the front-stage buffer body serves as the piston rod of the middle-stage buffer body and the cylinder body of the middle-stage buffer body serves as the piston rod of the tail-stage buffer body. A pressure sensor used for detecting the pressure of the medium is arranged on the right end face of the piston body assembly of the front-stage buffer body. The piston body assemblies of all the buffer bodies are suitable for adjusting the reciprocating flow of the medium in the corresponding cylinder bodies in the piston movement process according to the medium pressure detected by the pressure sensor, so that the moving speeds of pistons are controlled.

Owner:蒋超

A brick production line

ActiveCN103395608BShock mitigationExtend your lifeFluid-pressure actuatorsMechanical conveyorsProduction lineBrick

Owner:临沭县济才人力资源服务有限公司

Operation method of two-stage buffer capable of controlling buffering sequence stage by stage

InactiveCN103307179AExtend your lifeControl movement speedSpringsShock absorbersEngineeringTraffic flow

The invention relates to an operation method of a two-stage buffer capable of controlling a buffering sequence stage by stage. The two-stage buffer comprises a first stage buffer part and a final stage buffer part, wherein each of the first stage buffer part and the final stage buffer part comprises a columniform cylinder body; cylinder covers are arranged at open ends of the cylinder bodies in a sealing manner; a piston rod is movably matched with a center through hole of each cylinder cover in a sealing manner; piston body components are arranged at the right ends of the piston rods; the piston body components can make piston motion in the cylinder bodies, and are movably matched with inner walls of the cylinder bodies in a sealing manner; the cylinder body of the first stage buffer part forms the piston rod of the final stage buffer part; and pressure sensors for detecting medium pressures are arranged on the right end surfaces of the piston body components of the first stage buffer part and the final stage buffer part. The operation method of the two-stage buffer comprises the steps that the piston body components of both the buffer parts can adjust the medium traffic flows in the corresponding cylinder bodies according to the medium pressures detected by the pressure sensors to control the speed of the piston motion during the piston motion.

Owner:苏州胤宗智能科技有限公司

Full-automatic brick making system based on robot

The invention relates to a working method of a full-automatic brickmaking system. The full-automatic brickmaking system comprises a hydraulic forming machine used for pressing green bricks, an automatic feeder used for hanging and conveying a steam-curing car to a stacking area, a positioner used for limiting the steam-curing car to the stacking area, and a robot used for stacking the green bricks on the steam-curing car. The positioner comprises a support arm and a cylinder used for supporting or putting down the support arm. The positioner is fixed on the upper end face of a slider in sliding fit with a guide rail. A cushioning device is arranged at the left end of the guide rail and used for cushioning slider impact force generated when the steam-curing car impacts on the positioner, and the right end face of the cushioning device and the left end face of the slider are in close contact. The working method includes that when the steam-curing car impacts on the supported support arm, the cushioning device cushions the slider impact force so as to relieve pressure on the cylinder due to impact of the steam-curing car.

Owner:蒋盘君

A three-stage buffer suitable for step-by-step control of buffer sequence

InactiveCN103291820BExtend your lifeControl movement speedSpringsSolid based dampersThree levelControl theory

Owner:苏州威斯道智能科技有限公司

A working method of a two-stage buffer with a temperature protection device

InactiveCN103307172BControl work speedControl movement speedSpringsLiquid based dampersLiquid-crystal displayEngineering

The invention relates to a working method of a two-stage buffer with a temperature detecting device. The two-stage buffer comprises a first-stage buffer and a last-stage buffer; a cylinder cover is in sealed connection with the open end of a cylindrical cylinder; the central through hole of the cylinder cover is sealed and movably matched with a piston rod; the right end of the piston rod is equipped with a piston component; the piston component is suitable for performing piston movement in the cylinder, and is in movable and sealed match with the inner wall of the cylinder; the cylinder of the first-stage buffer constitutes the piston rod of the last-stage buffer; the right end surfaces of the piston components of the first-stage piston and the last-stage piston are equipped with a temperature sensor; the temperature sensor comprises a temperature sensor suitable for detecting medium temperature, and is connected with a processor module; the outer cylinder wall of the two-stage buffer is equipped with a liquid crystal display module; the processor module is suitable for displaying the medium temperature through the liquid crystal display module.

Owner:苏州胤宗智能科技有限公司

Operating method of buffer for adjusting piston motion according to impact pressure

ActiveCN103307193AExtend your lifeControl movement speedSpringsShock absorbersCylinder blockPiston rod

The invention relates to an operating method of a buffer. The bumper consists of a first-stage buffer, a transtage buffer and a final-stage buffer, each of which comprises a cylindrical cylinder body used for filling a buffering medium, wherein a cylinder cover is arranged at the open end of each cylinder body in a sealing manner, a piston rod is sealed in the central through hole of the cylinder cover in a movably matched manner, and a piston body component is arranged at the right end of the piston rod, is suitable for conducting piston motion in the cylinder body and is movably sealed fit with the inner wall of the cylinder body; the cylinder body of the first-stage buffer forms a piston rod of the transtage buffer, and the cylinder body of the transtage buffer forms a piston rod of the final-stage buffer; a pressure sensor used for detecting the medium pressure is arranged on the right end surface of the piston body component of the transtage buffer; the piston body components of the three buffers are suitable for adjusting the reciprocating flow rates of media in the corresponding cylinder bodies according to the medium pressure detected by the pressure sensor during piston motion so as to control the piston motion rates.

Owner:JIANGSU HENGYUAN HYDRAULIC

A working method of fully automatic brick making system

ActiveCN103398136BShock mitigationExtend your lifeSpringsAuxillary shaping apparatusBrickEngineering

Owner:临沭县济才人力资源服务有限公司

Working method of two-stage bumper with temperature protection function

ActiveCN103291805AControl work speedReduce work speedSpringsLiquid based dampersEngineeringMechanical engineering

The invention relates to a working method of a two-stage bumper with a temperature protection function, wherein the two-stage bumper comprises a head-stage bumper and a tail-stage bumper. The head-stage bumper and the tail-stage bumper respectively comprise a cylinder body of a cylinder shape, a cylinder cover is arranged on the opening end of each cylinder body in a sealing mode, a piston rod is movably matched in a center through hole of each cylinder cover in a sealing mode, a piston body assembly is arranged at the right end of each piston rod, suitable for conducting piston motion in each cylinder body, and movably matched with the inner wall of each cylinder body in a sealing mode. The cylinder body of the head-stage bumper forms the piston rod of the tail-stage bumper, temperature sensors are arranged on the right end faces of the piston body assembly of the head-stage bumper and the piston body assembly of the tail-stage bumper, the temperature sensors are suitable for detecting temperature of mediaand connected with a PLC, a nixie tube is arranged at the outer cylinder wall of the two-stage bumper, and the PLC is suitable for displaying the temperature of the media through the nixie tube.

Owner:苏州卫优知识产权运营有限公司

A working method of hollow block production line

Owner:临沭县济才人力资源服务有限公司

Full-automatic hydraulic forming brick making machine

ActiveCN103388647AShock mitigationExtend your lifeSpringsAuxillary shaping apparatusBrickMechanical engineering

The invention relates to a full-automatic hydraulic forming brick making machine, which comprises an automatic feeding machine and a positioner, wherein the automatic feeding machine is used for hauling a steam-curing car to a stacking area; the positioner is used for limiting the steam-curing car to the stacking area; the positioner comprises support arms and an air cylinder used for supporting or laying down the support arms; the positioner is fixedly arranged on the upper end face of a slider; the slider is in sliding fit with a guide rail body; the left end of the guide rail body is provided with a buffer device; the buffer device is used for buffering a slider impact force generated when the positioner is impacted by the steam-curing car. When the supported support arms are impacted by the steam-curing car, the slider impact force is buffered by the buffer device so as to relieve pressure received by the air cylinder and caused by the impact of the steam-curing car. According to the full-automatic hydraulic forming brick making machine provided by the invention, when the supported support arms are impacted by the steam-curing car, the impact force of the steam-curing car, received by the air cylinder, is buffered by the buffer device, and therefore, the impact force received by the air cylinder can be effectively relieved, and the service life of the air cylinder is effectively prolonged.

Owner:临沭县济才人力资源服务有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com