Hollow block palletizing device

A stacking device and hollow block technology, which is used in the field of hollow block and brick stacking devices, can solve the problems of easy damage of the locator, relieve the pressure in the cavity, have a wide range of applications, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

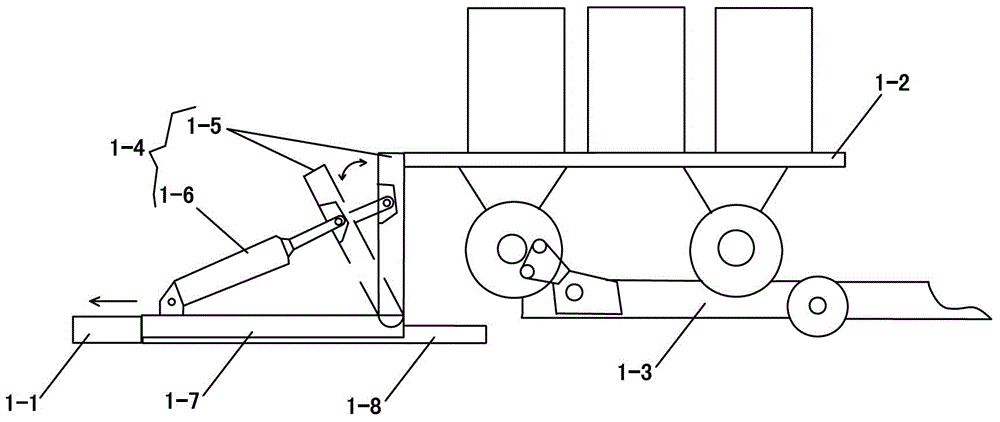

[0020] See figure 1 , a hollow block stacking device, comprising: an automatic feeder 1-3 for hanging and sending the steam curing car 1-2 to the stacking area, and used for limiting the steam curing car 1-2 to the stacking area The locator 1-4 in the area is used for the robot ( figure 1 not shown in ), the positioner includes: a support arm 1-5, one end of which is connected to a cylinder 1-6 on the left side of the support arm 1-5, and the cylinder 1-6 is used to prop up or lower the support arm ; The locator 1-4 is fixed on a slider 1-7, that is, the other end of the cylinder 1-6 and the bottom of the arm 1-5 are respectively connected to the left and right ends of the slider 1-7; This slider 1-7 is slidingly matched with a guide rail body 1-8, and the left end of the guide rail body 1-8 is provided with a buffer device 1-1, which is used for buffering by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com