Operation method of two-stage buffer capable of controlling buffering sequence stage by stage

A technology of two-stage buffers and working methods, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems that it is difficult to limit the working order of stage buffers, and achieve a wide range of applicable places and extended buffering effect on device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

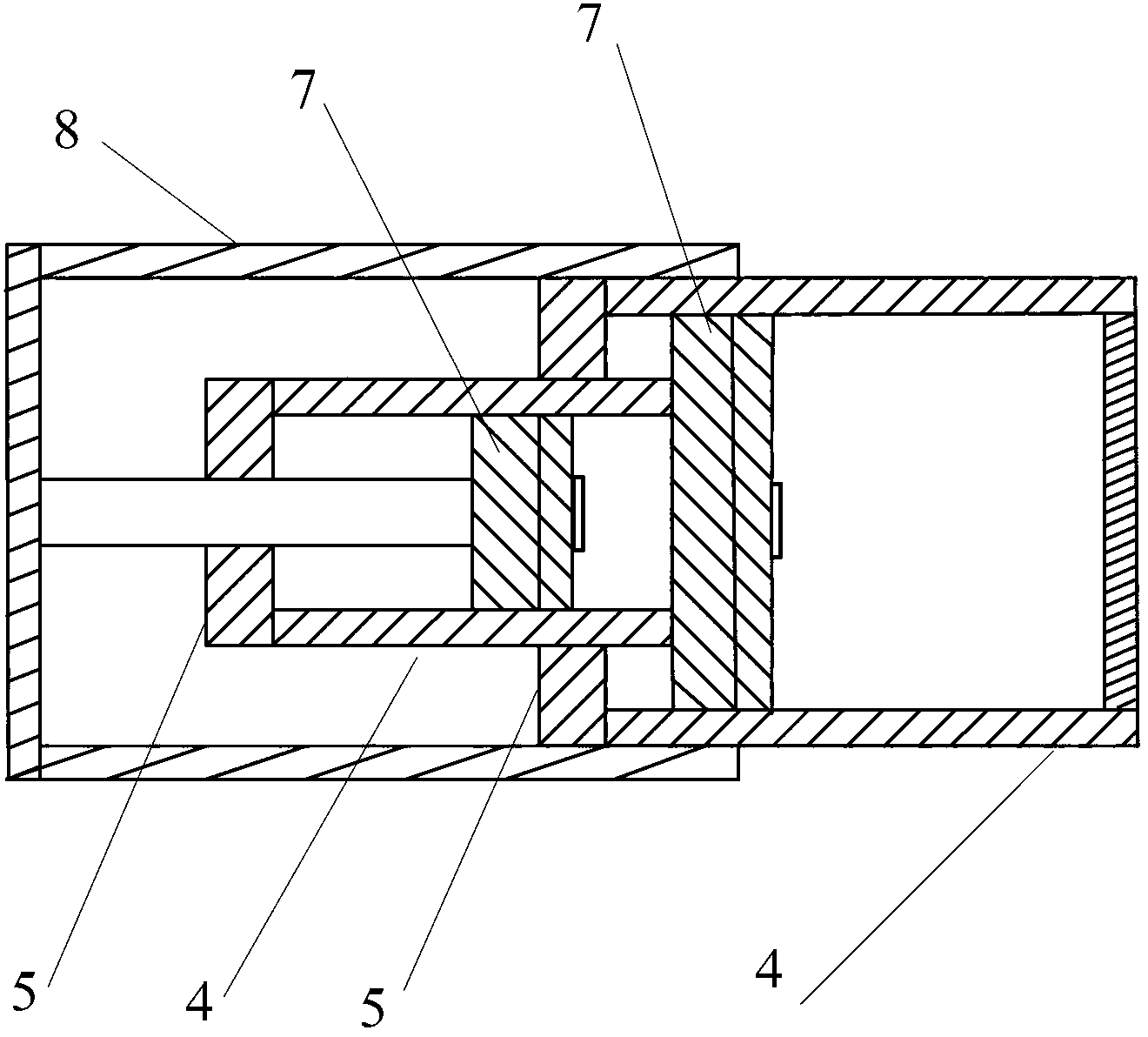

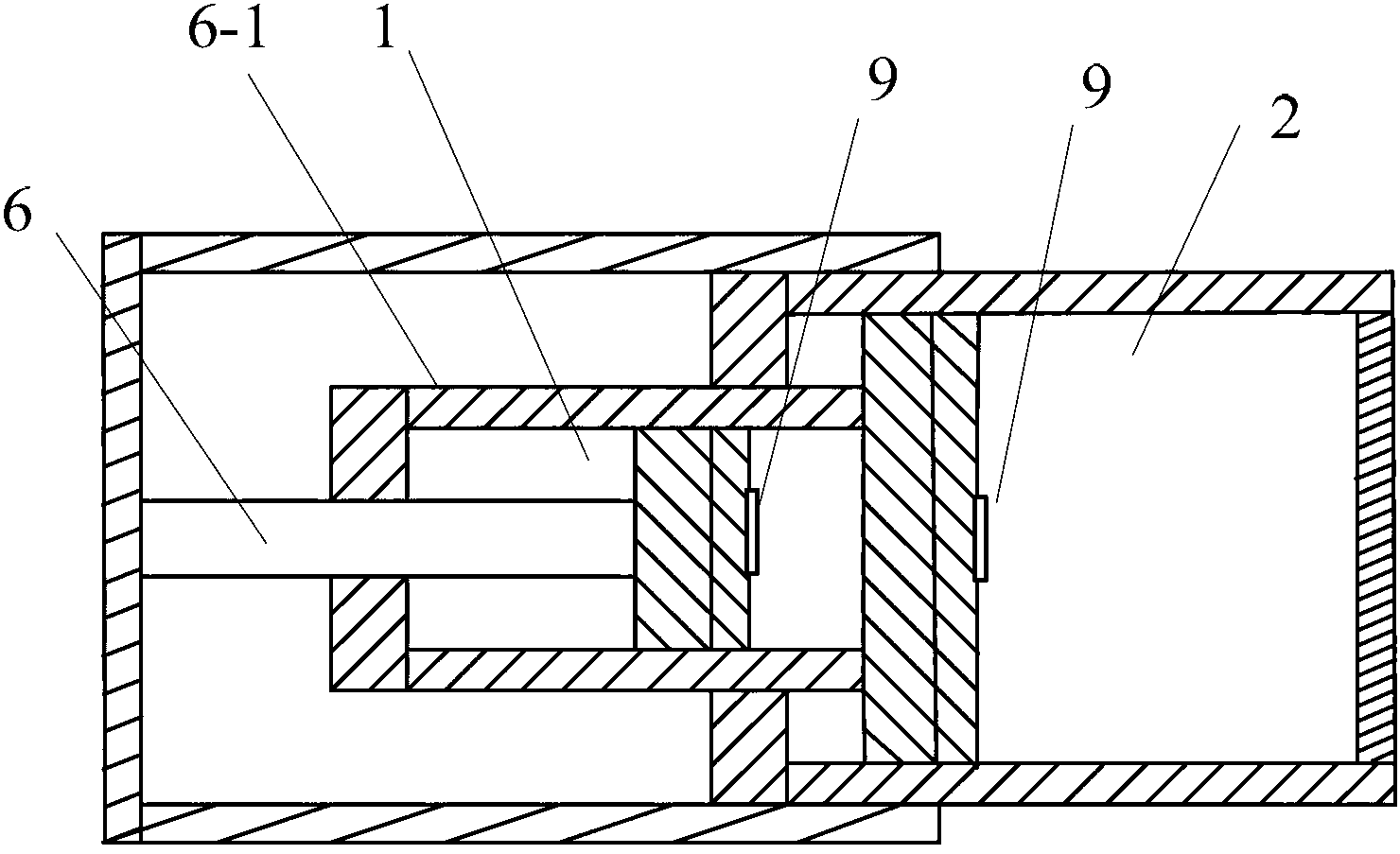

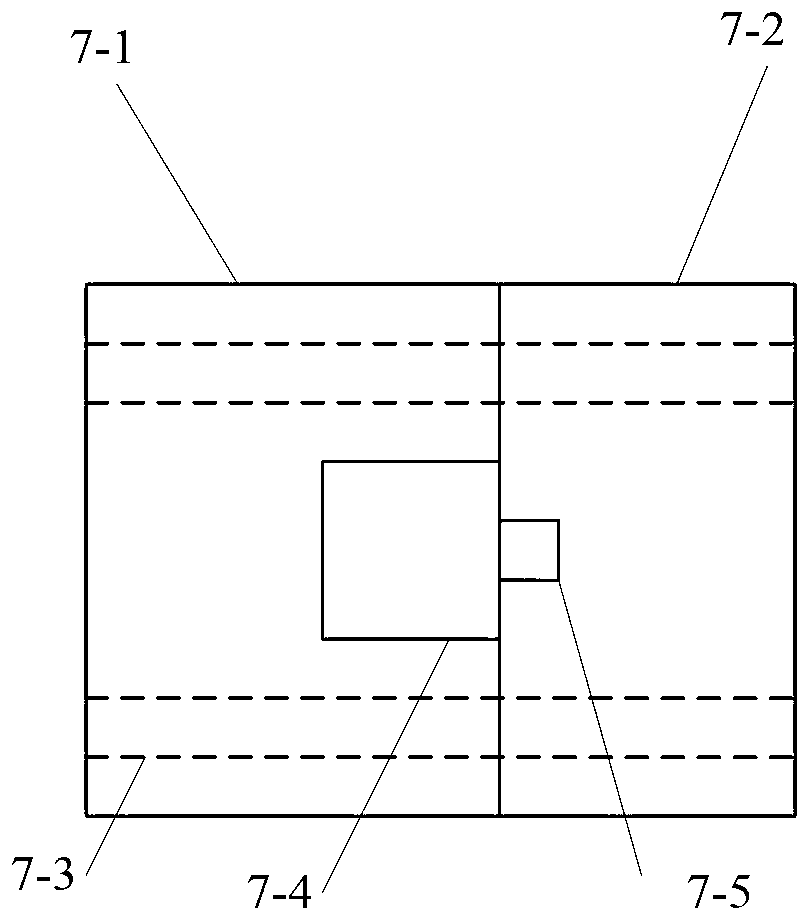

[0016] See figure 1 , figure 2 and Figure 5 , a working method of a two-stage buffer suitable for step-by-stage control of the buffer sequence, the two-stage buffer comprising: a first-stage buffer 1, a final-stage buffer 2; the first-stage buffer 1, the final-stage buffer The device 2 respectively includes: a cylinder body 4 which is cylindrical and is used to fill the buffer medium. A cylinder head 5 is sealed at the open end of the cylinder body 4, and a piston is fitted in the central through hole of the cylinder head 5 in a sealing manner. Rod 6, the right end of the piston rod 6 is provided with a piston body assembly 7, the piston body assembly 7 is suitable for piston movement in the cylinder body 4, and is movable and sealed with the inner wall of the cylinder body 4; wherein, the The cylinder body 4 of the first-stage buffer 1 constitutes the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com