Preparation method of acupuncture 3D sound-absorbing body

An acupuncture and 3D technology is applied in the field of the preparation of acupuncture 3D sound-absorbing bodies, which can solve the problems of incapable of environmental decoration, cleaning, complicated production process of sound-absorbing bodies, poor low-frequency sound-absorbing effect, etc., and achieves increased appearance effect and sound-absorbing performance. Improved, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

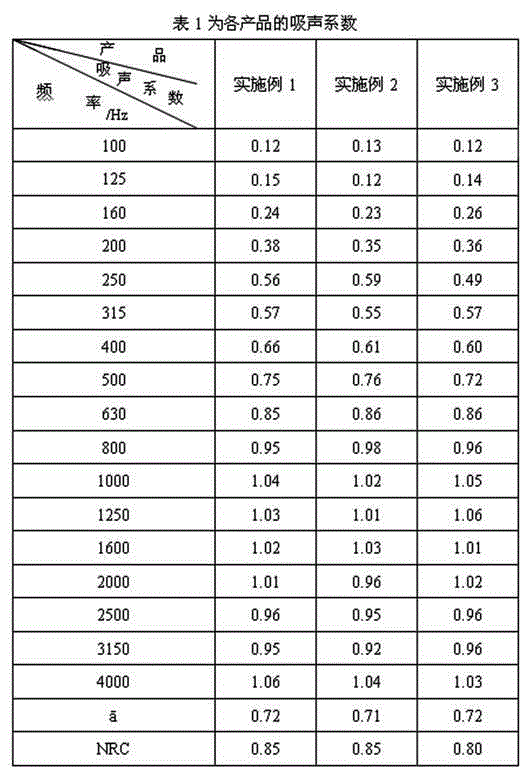

Embodiment 1

[0032] A method for preparing an acupuncture 3D sound-absorbing body, comprising the steps of:

[0033] (a) Weighing the first polyester staple fiber and the second polyester staple fiber at a mass ratio of 1:1;

[0034] (b) The weighed fiber enters the cotton rolling equipment for opening and mixing;

[0035] (c) The fiber processed by the rolling equipment is sent into the cotton mixing machine through the compression device, and the fiber is further mixed evenly;

[0036] (d) The fiber treated in step (c) enters the carding equipment, and forms a fiber web after opening;

[0037] (e) The fiber web enters the stacking equipment for stacking;

[0038] (f) After the piled fiber web is needled for the first time, a fiber cotton with a thickness of 25 mm is formed;

[0039] The needling density of the first needling is 1.6 needles / cm 2 ;

[0040] (g) Place a density of 200kg / m on the fiber cotton 3 cotton felt, and then perform the second needle punching to form needle pun...

Embodiment 2

[0049] A method for preparing an acupuncture 3D sound-absorbing body, comprising the steps of:

[0050] (a) weighing the first polyester staple fiber and the polyamide fiber at a mass ratio of 1:2;

[0051] (b) The weighed fiber enters the cotton rolling equipment for opening and mixing;

[0052] (c) The fiber processed by the rolling equipment is sent into the cotton mixing machine through the compression device, and the fiber is further mixed evenly;

[0053] (d) The fiber treated in step (c) enters the carding equipment, and forms a fiber web after opening;

[0054] (e) The fiber web enters the stacking equipment for stacking;

[0055] (f) After the piled fiber web is needled for the first time, a fiber cotton with a thickness of 30mm is formed;

[0056] The needling density of the first needling is 1.4 needles / cm 2 ;

[0057] (g) Place a density of 300kg / m on the fiber cotton 3 cotton felt, and then perform the second needle punching to form needle punched cotton fel...

Embodiment 3

[0066] A method for preparing an acupuncture 3D sound-absorbing body, comprising the steps of:

[0067] (a) weighing the first polyester staple fiber and the second polyester staple fiber at a mass ratio of 1:3;

[0068] (b) The weighed fiber enters the cotton rolling equipment for opening and mixing;

[0069] (c) The fiber processed by the rolling equipment is sent into the cotton mixing machine through the compression device, and the fiber is further mixed evenly;

[0070] (d) The fiber treated in step (c) enters the carding equipment, and forms a fiber web after opening;

[0071] (e) The fiber web enters the stacking equipment for stacking;

[0072] (f) The stacked fiber web is needled for the first time to form a fiber cotton with a thickness of 20mm;

[0073] The needling density of the first needling is 1.3 needles / cm 2 ;

[0074] (g) Place a density of 240kg / m on the fiber cotton 3 cotton felt, and then perform the second needle punching to form needle punched cot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com