Thermomechanical treatment method of 6000-series aluminum alloy

A technology of deformation heat treatment and aluminum alloy, which is applied in the field of deformation heat treatment of aluminum alloy to achieve the effect of eliminating the sensitivity of intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

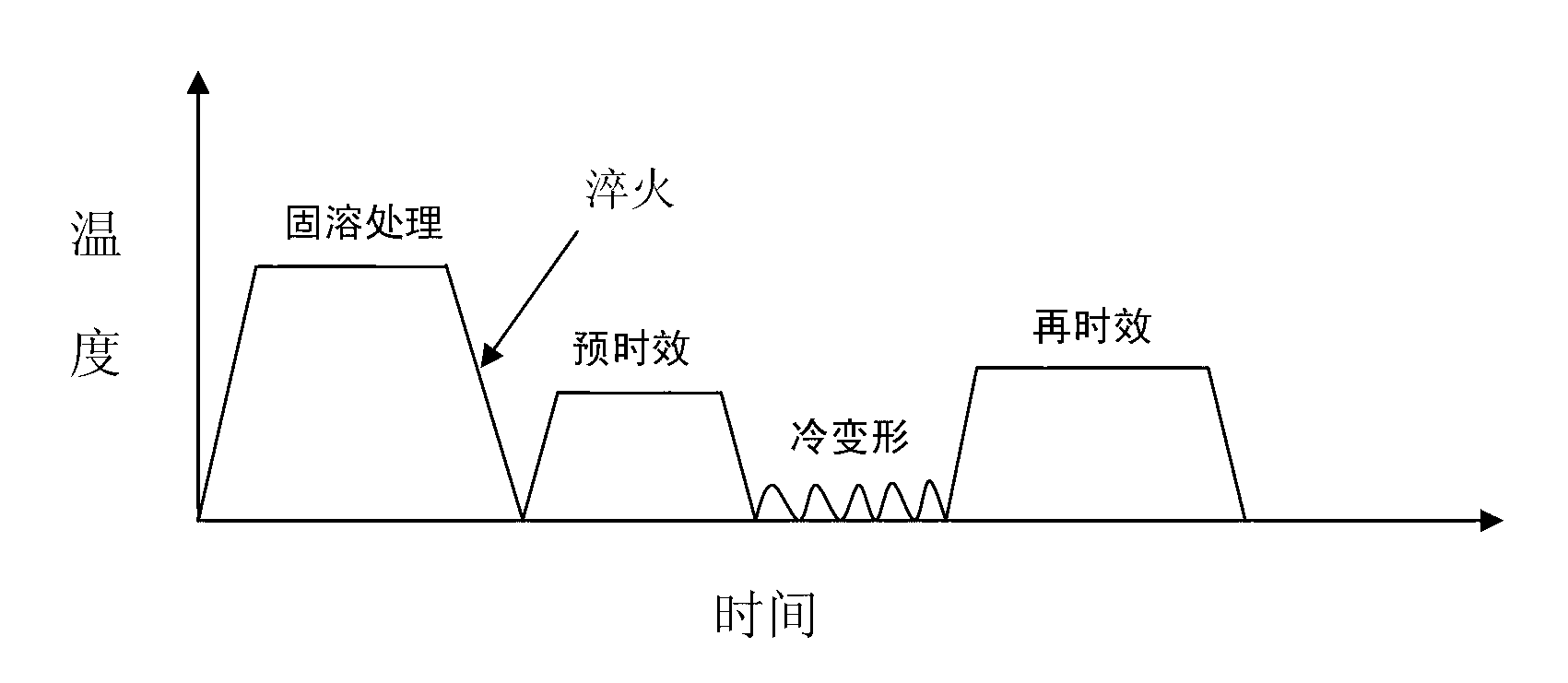

Method used

Image

Examples

Embodiment 1

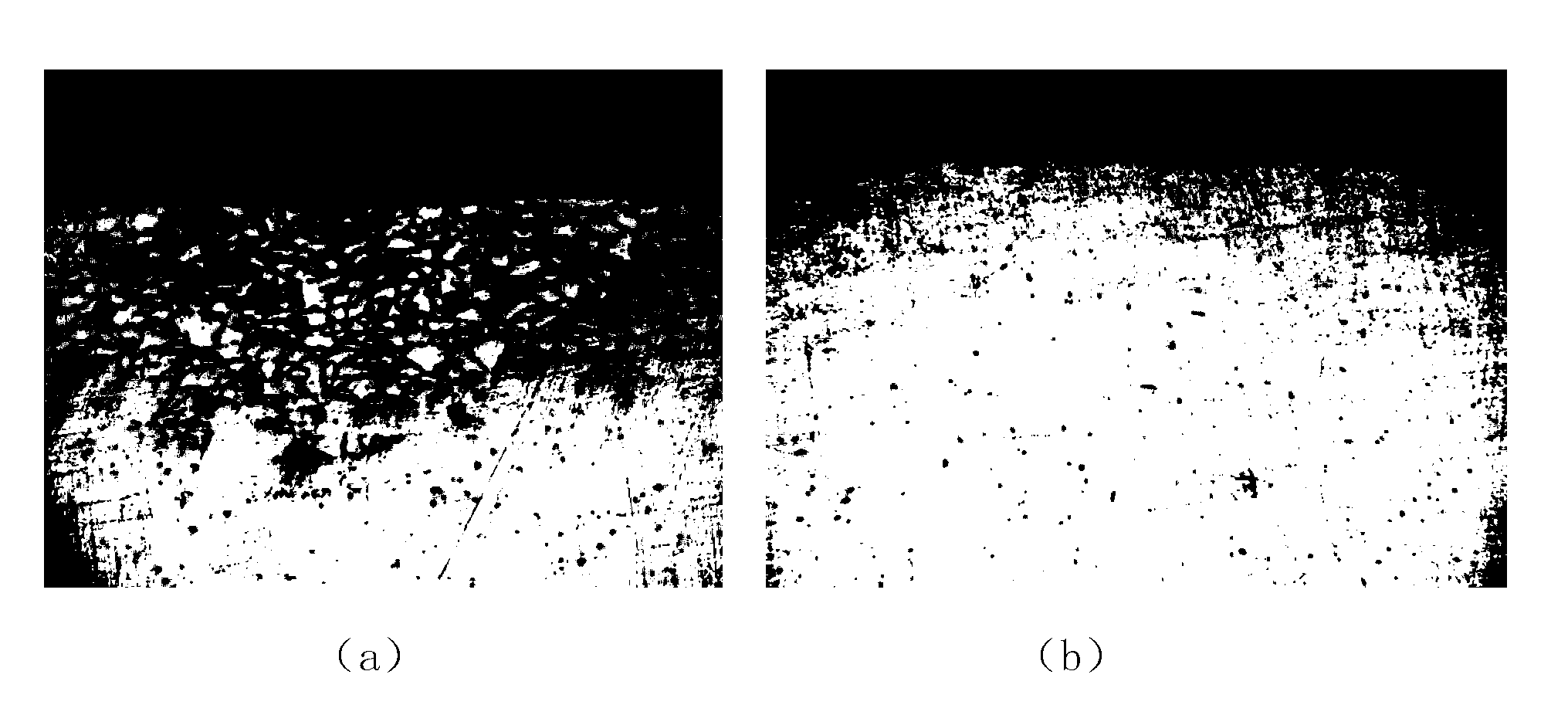

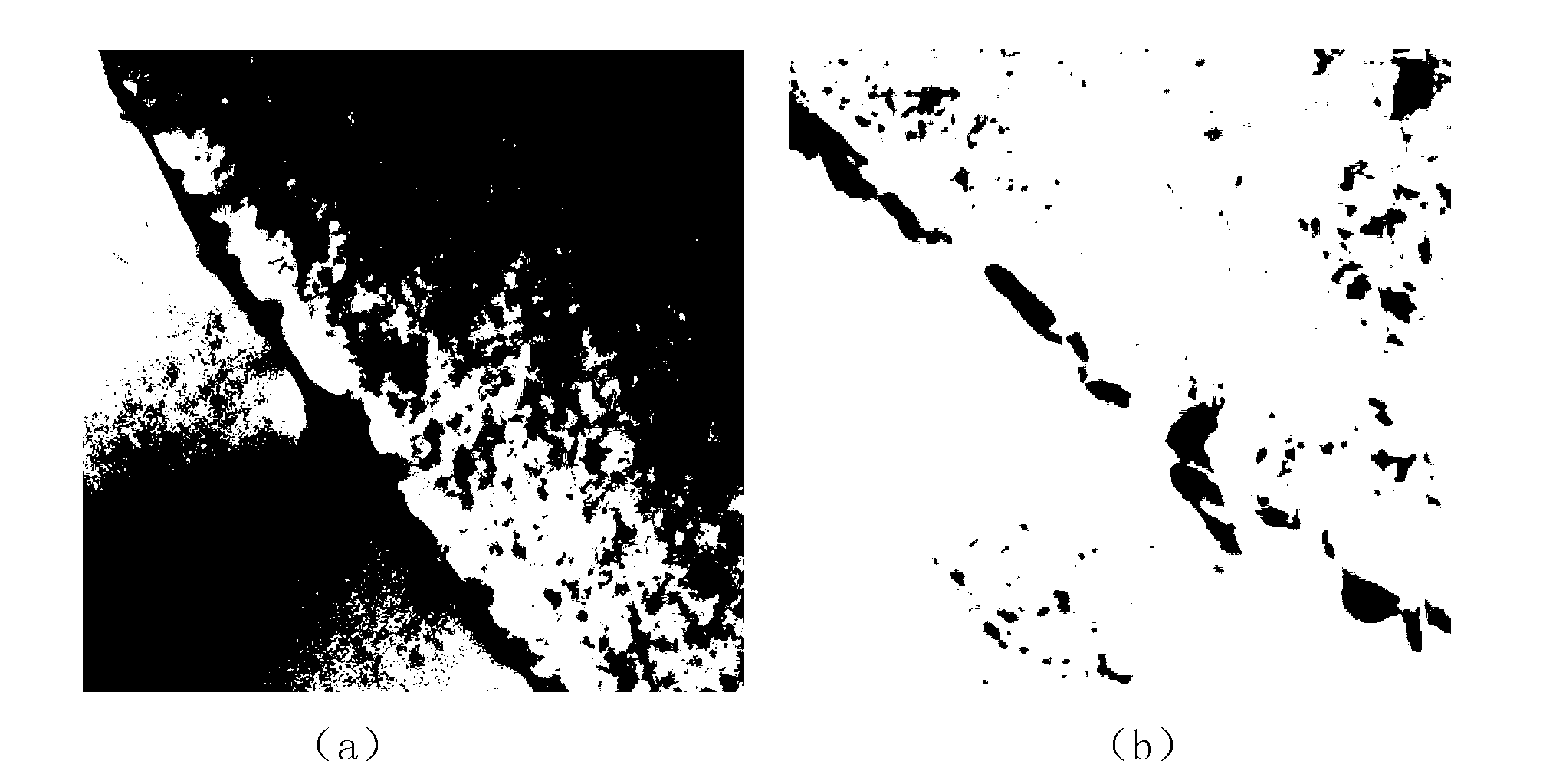

[0023] 6061 aluminum alloy hot-rolled plate, after 540℃ / 1h solution treatment and water quenching, firstly carry out 180℃ / 2h pre-aging, then carry out room temperature cold rolling deformation with a reduction of 75%, and finally carry out 175℃ / 6h aging. At this time, the tensile properties and corrosion types of the alloy are shown in Table 1, and the corrosion morphology is shown in Table 1. figure 2 b, TEM structure of the grain boundary region see image 3 b, tensile fracture morphology see Figure 4 b.

[0024] figure 2 Corrosion morphology of 6061 aluminum alloy under the conventional 540°C / 1h solution treatment, water quenching and T6 (180°C / 6h) aging treatment and 180°C / 2h+75% cold rolling deformation+175°C / 6h . figure 2 a shows that the T6 state 6061 aluminum alloy grains are separated from each other, showing a serious tendency of intergranular corrosion. And through 540 ℃ / 1h solution treatment of the present invention, water quenching and 180 ℃ / 2h+75% cold ...

Embodiment 2

[0028] 6061 aluminum alloy hot-rolled sheet, after solution treatment at 530°C / 1h and air cooling, firstly carry out 150°C / 24h pre-aging, then carry out cold rolling deformation at room temperature with a reduction of 80%, and finally carry out 160°C / 12h aging. At this time, the tensile properties and corrosion types of the alloy are shown in Table 1.

Embodiment 3

[0030] 6061 aluminum alloy hot-rolled sheet, after solution treatment at 530°C / 4h and water quenching, firstly carry out 190°C / 1h pre-aging, then carry out cold rolling deformation at room temperature with a reduction of 60%, and finally carry out 170°C / 10h Re-aging. At this time, the tensile properties and corrosion types of the alloy are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com