Temperature-resistant salt-resistant acrylamide terpolymer sulfonate oil-displacing agent and synthesis

An oil-displacing agent, temperature-resistant and salt-resistant technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of large viscosity loss, poor mechanical shear stability, limitations, etc., achieve viscosity increase, good durability Temperature and salt resistance, shear resistance, and rigidity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of tetrapolymer AM / NaAA / NAP / AMPS

[0027] According to the ratio in Table 1, first weigh acrylic acid and dilute it with 10g deionized water, slowly add sodium hydroxide in an ice bath, and cool to room temperature; add NAP to a 250mL three-necked flask, then add OP-10 and 10g deionized water, After fully stirring, add AM and AMPS after the emulsification is complete, then add sodium acrylate solution, adjust the pH to 7 with NaOH solution, and pass nitrogen for 20 minutes; then add initiator sodium bisulfite solution, then add ammonium persulfate solution, and pass nitrogen for 10 minutes , reacted at a temperature of 40-50°C for 10h; finally washed three times with absolute ethanol, pulverized, and dried at a constant temperature of 40°C to obtain the AM / NaAA / NAP / AMPS tetrapolymer.

[0028] Table 1 Addition amount of quaternary polymer synthetic drugs

[0029]

Embodiment 2

[0030] Embodiment 2: AM / NaAA / NAP / AMPS tetrapolymer structure characterization

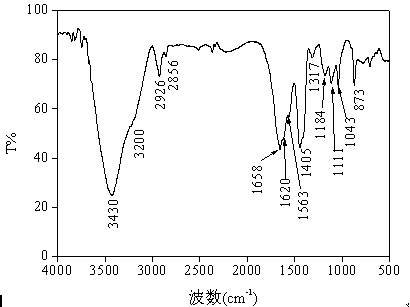

[0031] The infrared spectrogram of the tetrapolymer AM / NaAA / NAP / AMPS synthesized by embodiment 1 is as follows figure 1 shown. From the figure, we know that 3430cm -1 Attributed to O-H stretching vibration, N-H stretching vibration at 3200cm -1 ,-CH 2 CH 3 The C-H stretching vibration peaks on the group are respectively at 2926cm -1 and 2856cm -1 at 1620cm -1 , 1563cm -1 It is the absorption peak of benzene ring; -C=O stretching vibration peak is at 1658cm -1 , 1184cm -1 and 1043cm -1 Corresponds to -SO 3 - The peak of the group, through the analysis of the absorption peak of the above infrared spectrum, it can be determined that the substance is consistent with the target product.

Embodiment 3

[0032] Embodiment 3: AM / NaAA / NAP / AMPS tetrapolymer solution apparent viscosity and concentration relation investigation

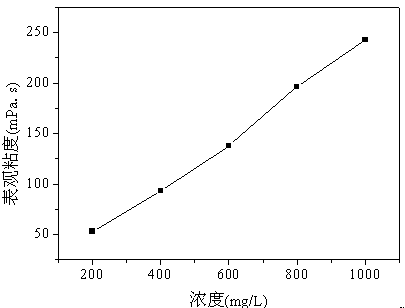

[0033]The tetrapolymer AM / NaAA / NAP / AMPS synthesized in Example 1 was formulated into a solution of 0.1 to 1 wt%, and the apparent viscosity of the solution was measured at 30°C. The experimental results were as follows: figure 2 shown. From figure 2 It can be obtained: when the concentration of the polymer solution is 200mg / L, the apparent viscosity is 53mPa·s; when the concentration is 600mg / L, the apparent viscosity is 148mPa·s; when the concentration is 1000mg / L, the apparent viscosity is 243mPa·s, As the concentration increases, the viscosity rises faster, so the tetrapolymer has better viscosity-increasing properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com