Microbial agent and preparation method as well as application thereof

A technology for microbial inoculants and seeds, applied to microbial inoculants and their preparation methods and application fields, can solve the problems of high requirements for composting equipment, incomplete fiber degradation, long composting time, etc., and achieve good control effect and bacterial species composition structure. Simple, fast fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 bacterial agent

[0026] 1) Fermentation of Bacillus subtilis and Bacillus megaterium

[0027] LB medium: yeast powder 5 g / L, peptone 10 g / L, NaCl 10 g / L, pH 7.0, sterilized at 121°C for 25 min.

[0028] The fermentation medium involved in the seed tank and fermenter: glucose 5 g / L, peptone 10 g / L, NaCl 10 g / L, pH 7.0, sterilized at 121°C for 25 min.

[0029] Inoculate the slant strains stored at 4°C in a 250 mL shake flask filled with 100 mL LB medium, activate and culture at 35°C, 170 r / min for 24 h, and then inoculate the activated bacterial liquid with 10% (v / v) The inoculum was transferred into a 1000 mL shake flask filled with 500 mL LB medium, and cultured at 35 °C and 170 r / min for 12 h to obtain a seed liquid.

[0030] Put the above seed liquid into the fermentation medium in the seed tank at the inoculum amount of 10% (v / v), ferment and cultivate at 35°C and 180 r / min for 24 h, ferment the seed liquid, and then add the ferment...

Embodiment 2

[0040] The preparation of embodiment 2 bacterial agents

[0041] The preparation of bacterium and fungal fermentation broth is identical to 1 and 2 in embodiment 1, the fermentation broth of Bacillus subtilis, Bacillus megaterium, Trichoderma longibranchus and Aspergillus niger is in mass ratio 1: 1: 1: 1 Mix evenly, then adsorb on vermiculite according to the mass ratio of 1:5, and then dry at 35~40°C until the water content is lower than 15%, and it will be ready after testing according to the standard of agricultural microbial agent (GB 20287-2006). Obtain the bacterial agent.

Embodiment 3

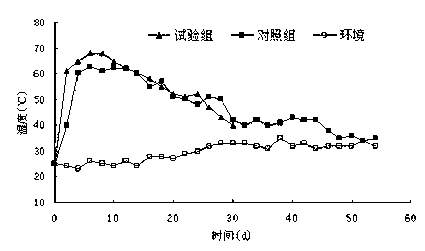

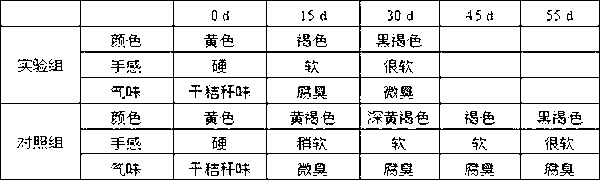

[0042] Example 3 Test of composting wheat straw with microbial inoculum

[0043] Crush the wheat straw into straw sections of 10-15 cm, and add the microbial agent prepared in Example 1 at a mass ratio of 2%. Mix the soil, and then mix the mixture and straw evenly, adjust the water content of the pile to about 55-65%, and pile the compost into strips according to the length, width and height of 2 m×1.5 m×1 m. After composting for about 2 days, the temperature When the temperature rises to 60°C, the piles are turned over to supply oxygen in sequence. The piles are turned once every 8 days, and the piles are turned twice in total. The body volume is reduced to about 1 / 2 of the original, that is, high-efficiency wheat straw organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com