Method for preparing, preserving and using silicon plate cured with hyaluronic acid

A technology of hyaluronic acid and preservation method, applied in the application field of bioactive materials, can solve the problems of low adhesion, difficult application, and easy loss of biological activity of hyaluronic acid film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Preparation of a silicon plate with a high degree of hydration polymer film

[0018] The silicon plate cured with hyaluronic acid described in the present invention is to carry out functional transformation on the surface of hyaluronic acid and silicon substrate by means of chemical modification, and anchor the hyaluronic acid polymer on the substrate interface. The polymer layer thus formed will exhibit a ring, brush or spread structure. By silanizing the surface of silica, the carboxyl group of hyaluronic acid can form an amide bond with the amino group on the surface of the base layer to be anchored on the surface of the base layer. One preparation method is as follows:

[0019] First place the wafer in piranha solution (hydrogen peroxide H 2 o 2 : concentrated sulfuric acid H 2 SO 4 =3:7) Soak for 5 hours and then rinse with deionized water several times until the silicon surface is completely clean, ensuring that the surface is free of any substances...

Embodiment 2

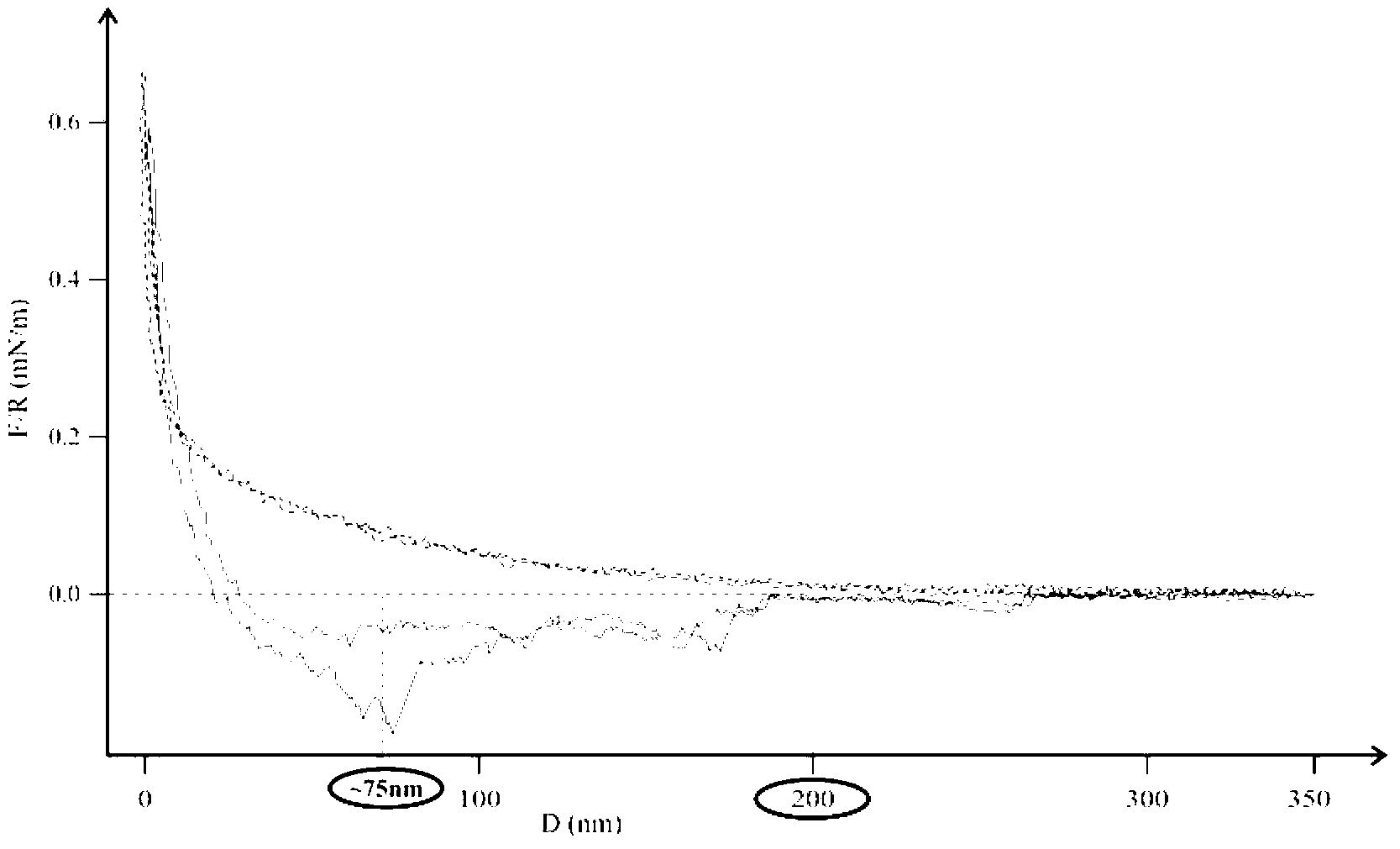

[0026] Use a molecular weight of 10 6 The hyaluronic acid molecules are fixed on the surface of the silicon substrate by the method of the present invention, so that a layer of highly hydrated polymer hyaluronic acid layer is formed on the surface of the silicon substrate. The applicant has found in long-term research that under solution conditions, if there are no other external ions, or when there are only monovalent cations, such as hydrogen ions, sodium ions, potassium ions, etc., the silicon plate prepared by the present invention is combined with another silicon plate. When they are close to each other in the aqueous solution environment, when the distance between them reaches a certain nanometer scale, about 200-400 nanometers, the two plates begin to repel each other, and the closer the repulsion between them is, the greater the repulsion force will be. The repulsion strength is about F / R>0.2mN / m. But when 1mM MgCl is added to the solution 2 Or similar divalent catio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com