Method for eliminating nano porous layer on surface of titanium dioxide nano tube array

A nanotube array and nanoporous technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve problems such as operational obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

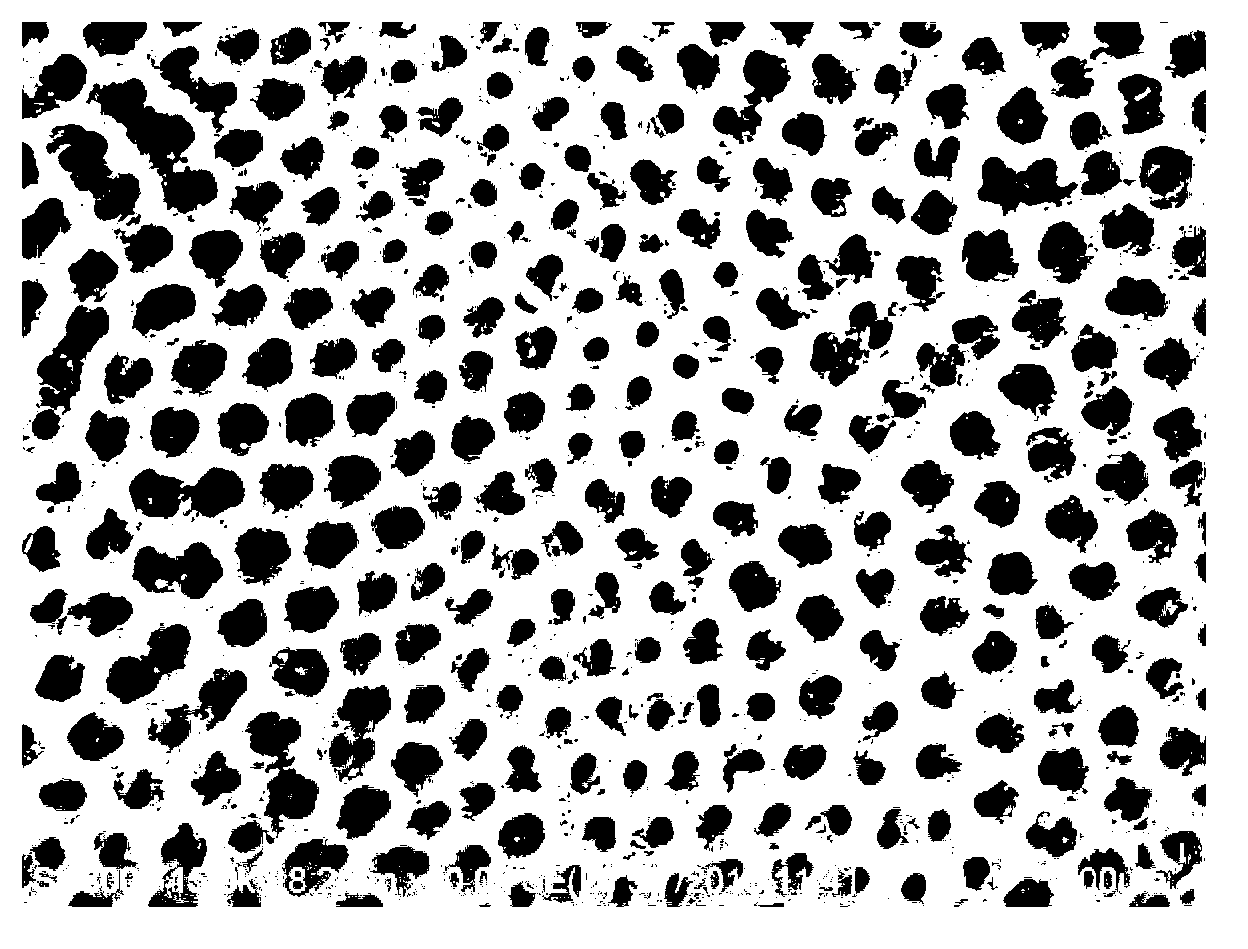

[0027] Specific embodiment one: the method for removing the nanoporous layer on the surface of a titanium dioxide nanotube array according to the present embodiment is carried out in the following steps:

[0028] 1. Preparation of impregnation solution: Weigh deionized water, hydrofluoric acid with a mass concentration of 40% and nitric acid with a mass concentration of 65% to 68% and mix them evenly to obtain an impregnation solution; wherein the hydrofluoric acid with a mass concentration of 40% The volume ratio with deionized water is (0.2~1): 100, and the volume ratio of the hydrofluoric acid with the mass concentration of 40% to the nitric acid with the mass concentration of 65%~68% is 1: (4~5);

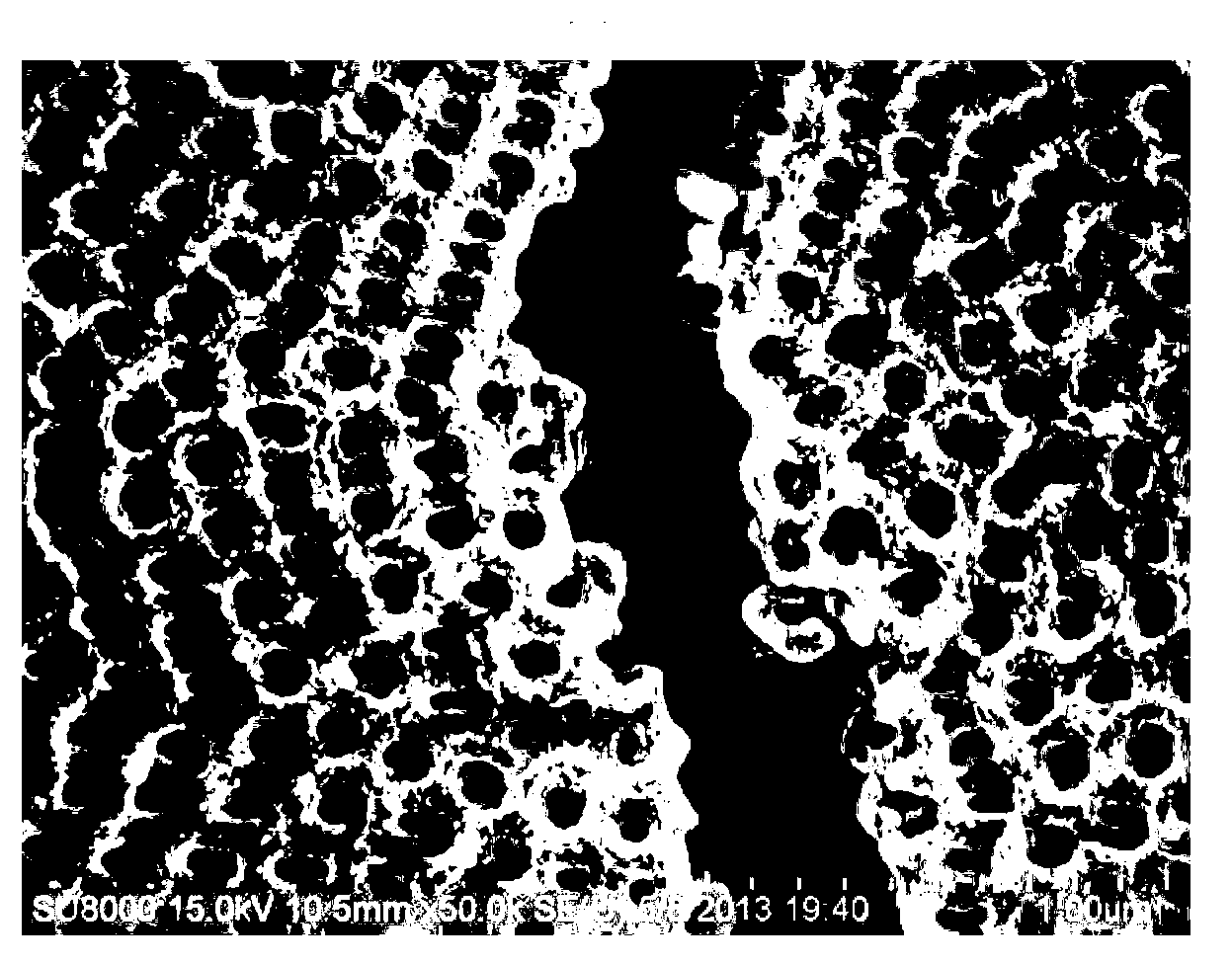

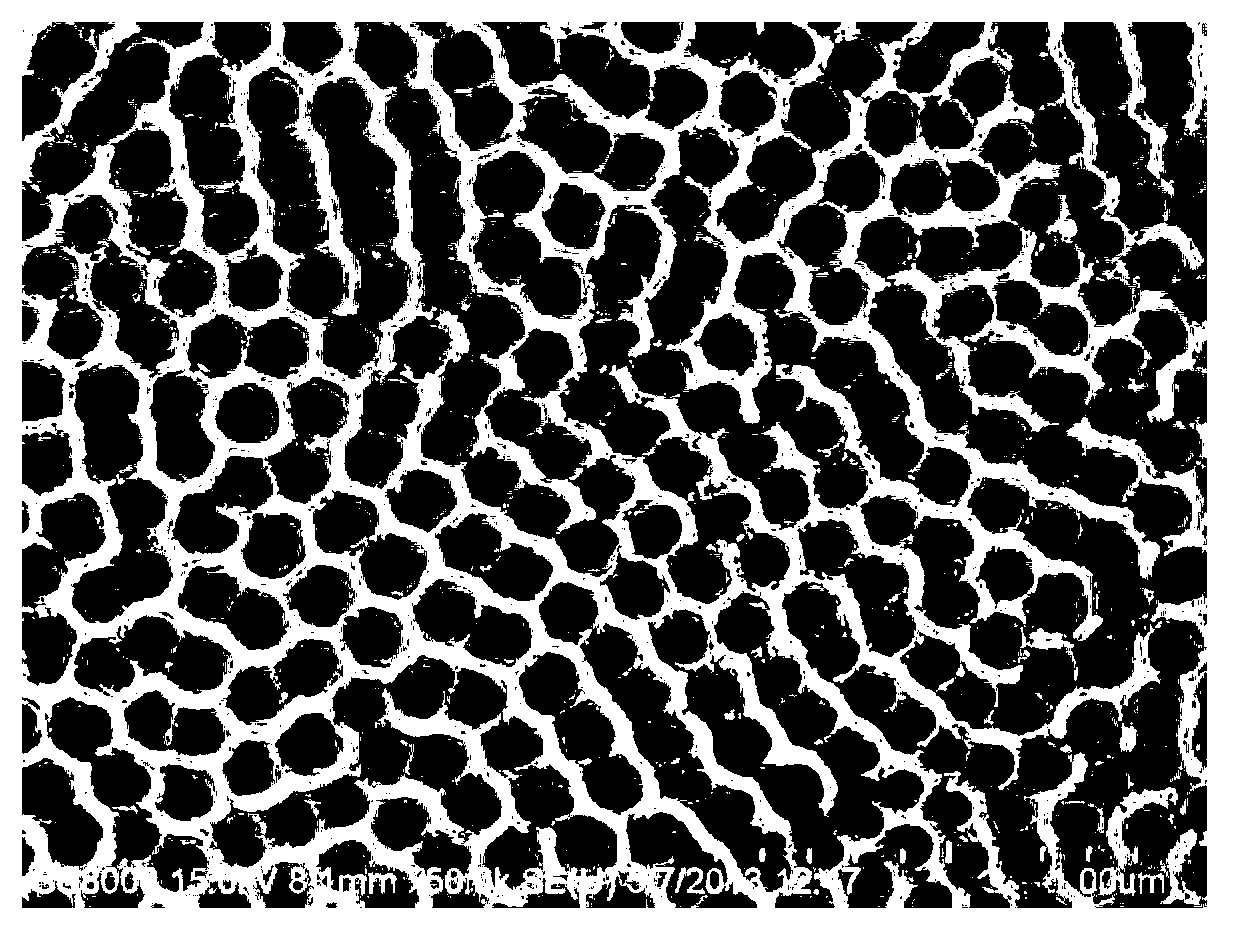

[0029] 2. Remove the film: immerse the titanium dioxide nanotube array covered with nanoporous layer in the immersion solution prepared in step 1, take it out after immersion for 2 to 20 minutes, and rinse it with deionized water. The nanoporous layer covered on the surface of th...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of the titanium dioxide nanotube array that the surface covers the nanoporous layer in the step 2 is carried out according to the following steps:

[0031] a. Pretreat the surface of a pure titanium plate with a purity ≥ 99.9%; b. Use deionized water, ammonium fluoride, and ethylene glycol to prepare an electrolyte, wherein ethylene glycol is a solvent, and the mass concentration of ammonium fluoride is 0.2 %~0.3%, the volume concentration of deionized water is 1.0%~5.0%; c, in the electrolytic solution prepared in step b, the pure titanium plate processed with step a is used as the anode, graphite is the cathode, and the voltage is 50~60V The anodic oxidation is carried out under the condition of the constant voltage mode, and the time is 1-1.3h, and the titanium dioxide nanotube array whose surface is covered with the nanoporous layer is obtained. Oth...

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the pretreatment described in step a is specifically carried out according to the following steps: the pure titanium plate with a purity ≥ 99.9% is sequentially used with 600#, 1000#, 2000# gold Grind with sandpaper until there are no visible traces on the surface, then put it in acetone for ultrasonic cleaning, then wash it with deionized water, then soak it in chemical lotion for chemical cleaning, and finally clean it with deionized water, dry, and complete the preparatory process. treatment; wherein the chemical washing liquid is mixed by hydrofluoric acid, nitric acid and water according to the volume ratio of 1:4:5, the mass concentration of hydrofluoric acid is 40%, and the mass concentration of nitric acid is 65%-68 %; the immersion time of chemical cleaning is 30-60 seconds; the impurities and oxide layer on the surface of the pure titanium plate are removed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com