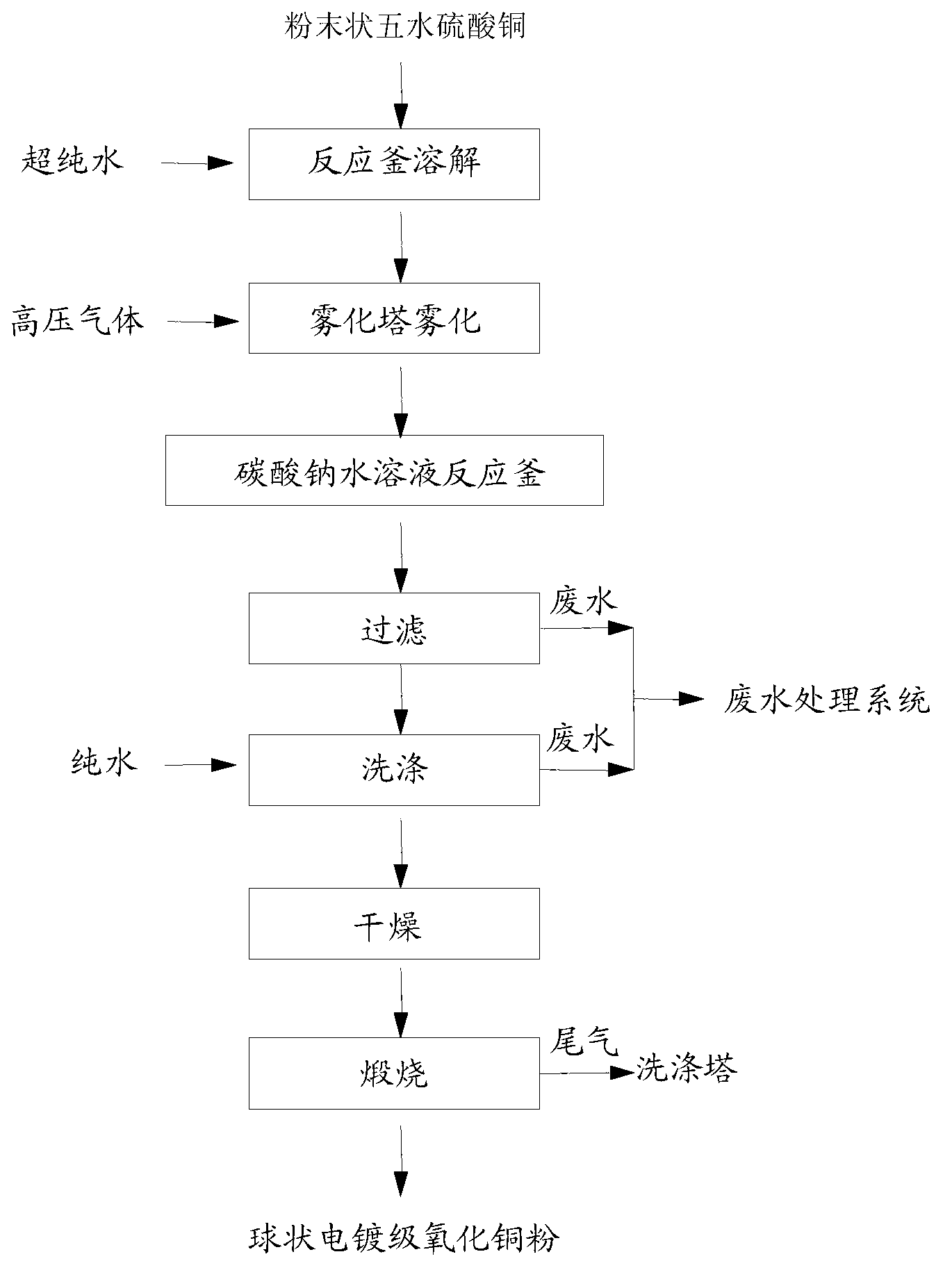

Preparation method of spherical electroplating-level copper oxide powder

An electroplating grade copper oxide, spherical technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of insufficient dissolution of copper oxide powder, slow dissolution rate, waste of materials, etc., to achieve good dispersion, stable product performance, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of spherical electroplating grade copper oxide powder, specifically comprising the following steps:

[0025] (1) Add 255kg of ultrapure water and 127.5kg of powdered copper sulfate pentahydrate into a 500L reaction kettle, then heat to 70°C and stir to fully dissolve to prepare a copper sulfate solution;

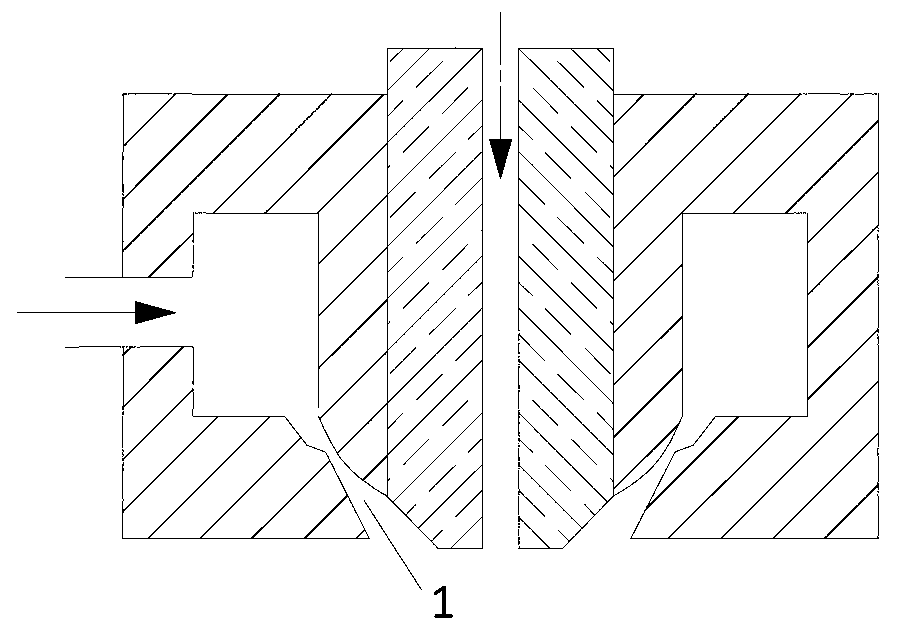

[0026] (2) The copper sulfate solution is injected into the atomization tower through the high-pressure atomization nozzle with retractable structure nozzle 1, and the high-pressure atomization nozzle is as figure 2 As shown, the spherical copper sulfate crystal droplet is obtained after being atomized by a high-pressure gas with a gas pressure of 4 kg;

[0027] (3) Spherical copper sulfate crystal droplets are naturally cooled in the atomization tower and directly enter the 3000L reaction kettle with 1700L sodium carbonate aqueous solution, and stir. The reaction temperature is controlled at 75°C, and all the materials in the spray tower enter t...

Embodiment 2

[0031] A preparation method of spherical electroplating grade copper oxide powder, specifically comprising the following steps:

[0032] (1) Add 700kg of ultrapure water and 280kg of powdered copper sulfate pentahydrate into a 1500L reactor, then heat to 70°C and stir to fully dissolve to prepare a copper sulfate solution;

[0033] (2) The copper sulfate solution is injected into the atomization tower through the high-pressure atomization nozzle with retractable structure nozzle 1, and the high-pressure atomization nozzle is as figure 2 As shown, the spherical copper sulfate crystal droplet is obtained after being atomized by a high-pressure gas with a gas pressure of 5 kg;

[0034] (3) Spherical copper sulfate crystal droplets are naturally cooled in the atomization tower and directly enter the 5000L reaction kettle with 2800L sodium carbonate aqueous solution, and stir. The reaction temperature is controlled at 65°C, and all the materials in the spray tower enter the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com