Fully-automatic glasses looping machine structure

A fully automatic, loop-bending technology, which is applied to other household appliances, frames, household appliances, etc., can solve the problems of only bending loops and pressing beams, heating dependence, and damage to products due to accuracy, and achieves automatic feeding and heating and reclaiming, the effect of automatic feeding heating and reclaiming automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

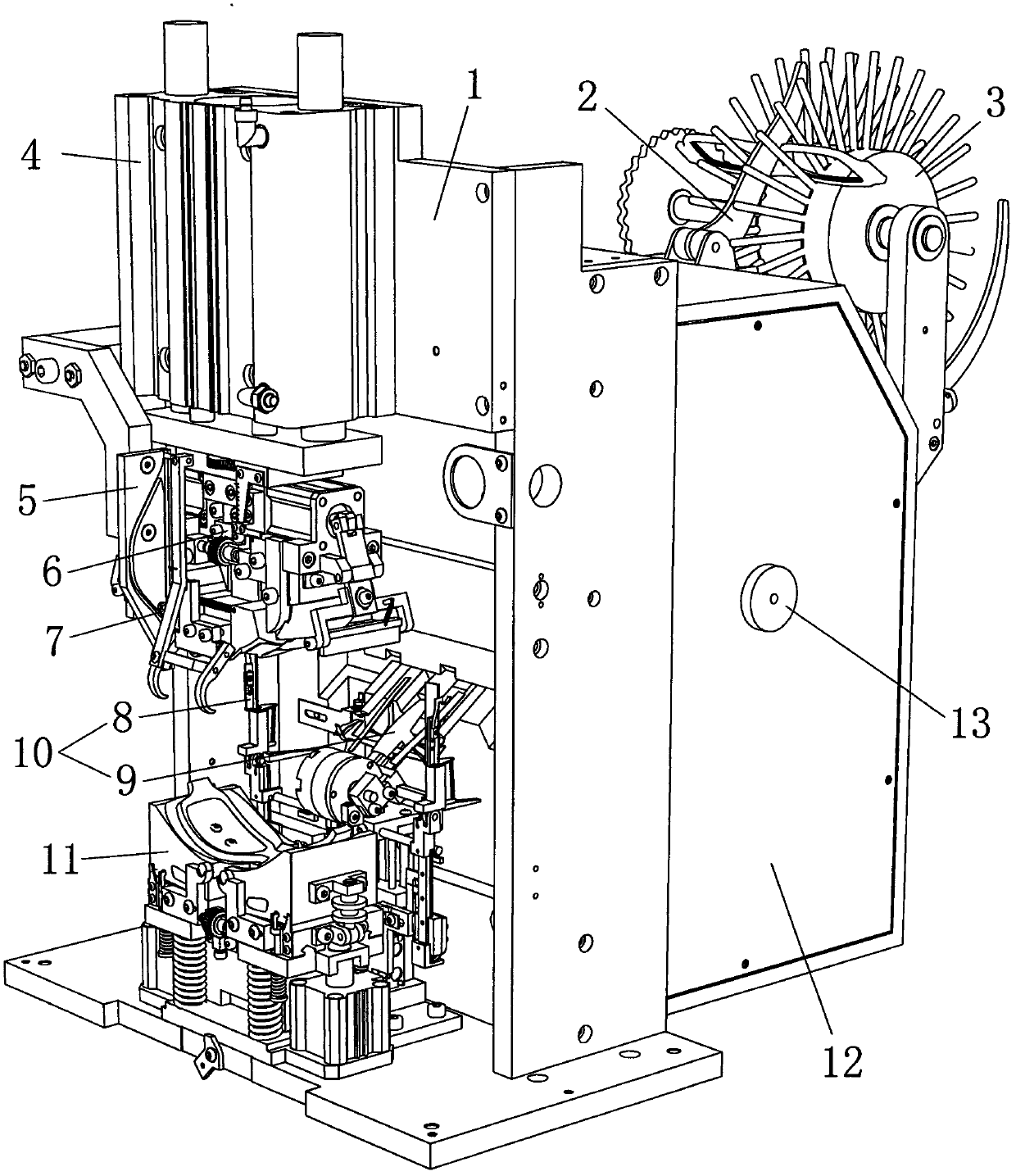

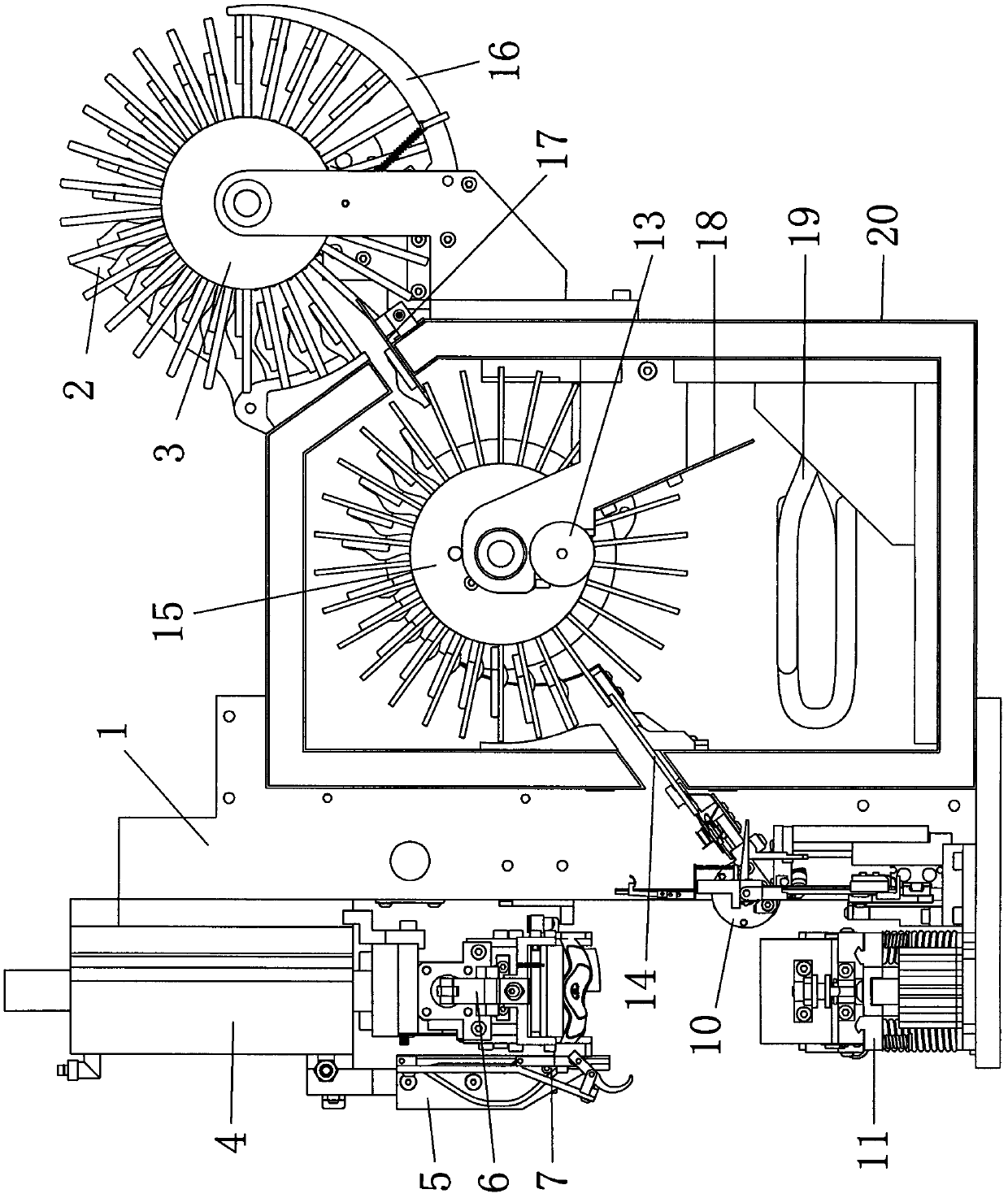

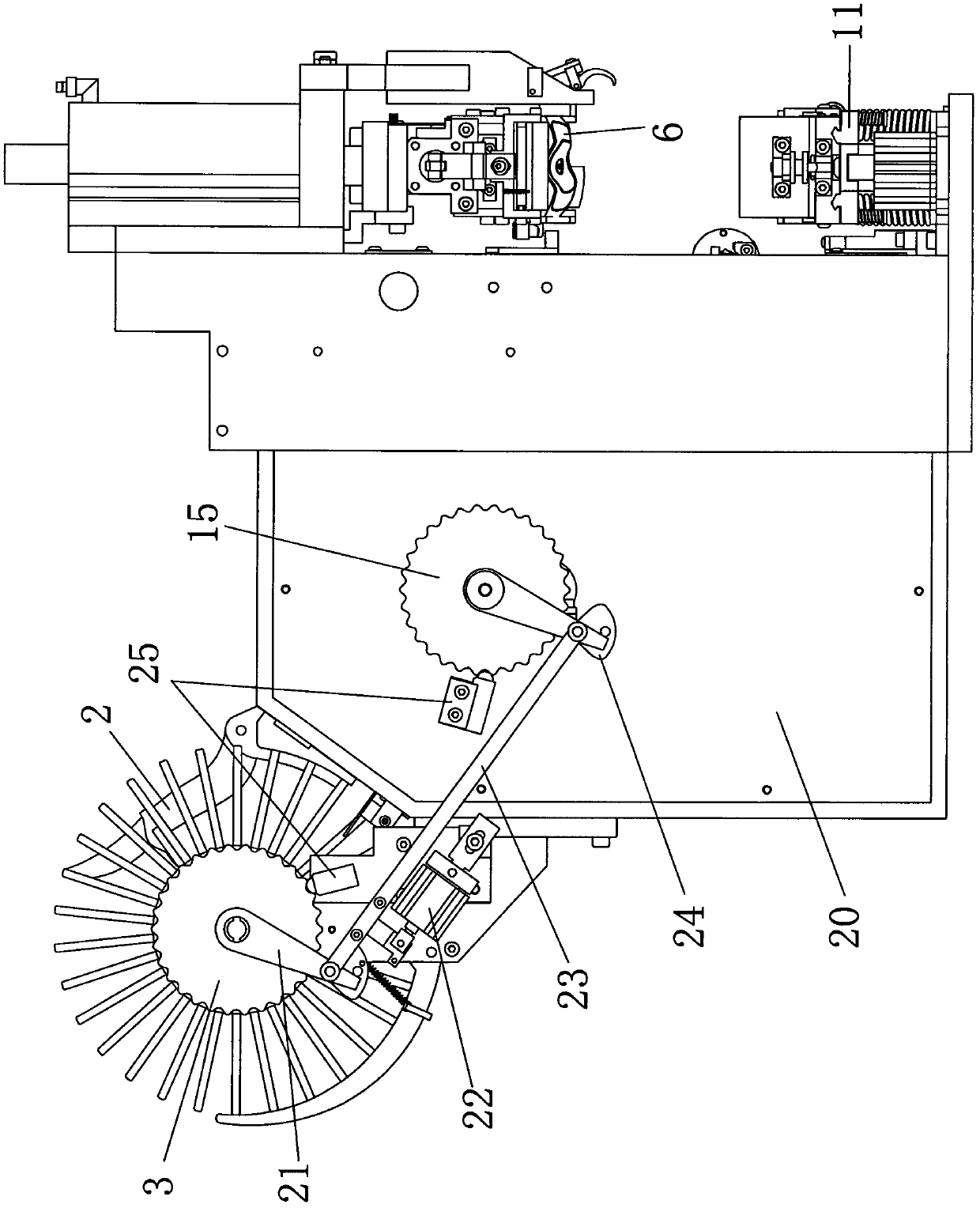

[0033] A kind of fully automatic eyeglass bending machine structure, such as figure 1 , figure 2 and image 3 As shown, it comprises a heating system 12, a manipulator device 10, an upper mold body 6, a lower mold body 11 and a main frame 1. At the moving end, the lower mold body 11 is installed on the bottom plate directly below it, and the heating system 12 is lapped on the back of the bottom plate of the main frame 1. The manipulator device 10 is fixed on the heating system 12 and the lower mold body 11 by combining the auxiliary finger 8 and the finger frame 9 between; the heating system 12 is provided with a discharge wheel 3 and a baking wheel 15, which are respectively installed inside and outside the oven 20 to form a certain height difference, and the shaft ends are connected by a traction strip 23, and a thin cylinder 22 is installed on the traction strip 23 ;Cooperate Figure 9 As shown, the upper mold body 6 is provided with a main pressing group 91 and a clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com