Method for fixing small column-shaped metal body arrays

A fixing method and columnar technology, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of inability to achieve uniform flow/electric field distribution and efficient removal of processed products, the size and length of metal tiny cylinders vary, and the metal tiny The problem of small size of the columnar body can achieve the effect of fixed arrangement and electrical connection, small effect of force and heat, and small deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

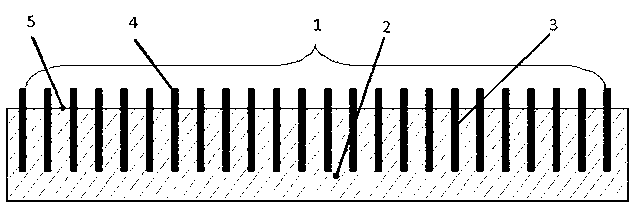

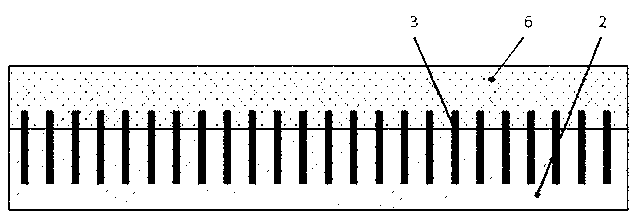

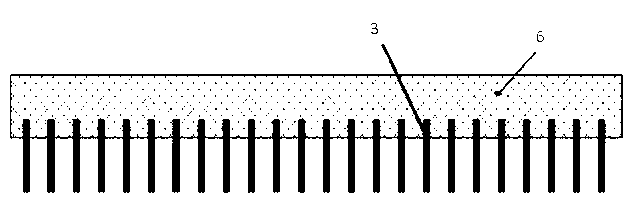

[0021] Combine below figure 1 , figure 2 and image 3 The specific implementation process of the present invention - "a method for fixing metal micro-pillar arrays" will be further described in detail.

[0022] (a) Insert several metal micro-pillar arrays 1 regularly on the paraffin layer 2 with a thickness of 2 mm, so that the roots 4 of the metal micro-columnar bodies 3 with a diameter of 200 μm and a length of 1 mm are exposed on the surface of the paraffin layer 2 by 50 μm.

[0023] (b) Electroplating a copper metal layer 6 with a thickness of about 1 mm on the surface 5 of the paraffin layer where the roots 4 of the metal micro-columnar bodies 3 are exposed.

[0024] (c) Melting to remove paraffin layer 2.

[0025] Through the above method steps, the regular and reliable fixation of the metal micro-pillars on the copper metal layer can be realized.

[0026] The above are specific embodiments of the present application, and it should be understood that these embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com