Devices and circuits with programmable metallization cells and methods of operation and manufacture thereof

A technology of metallization and storage unit, which is applied in the fields of storage devices and integrated circuits and their operation and manufacture, and can solve the problems of increasing the thickness and/or area of storage structures by separating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following examples are given in particular, and in conjunction with the attached Figure 1 to Figure 11 , as detailed below.

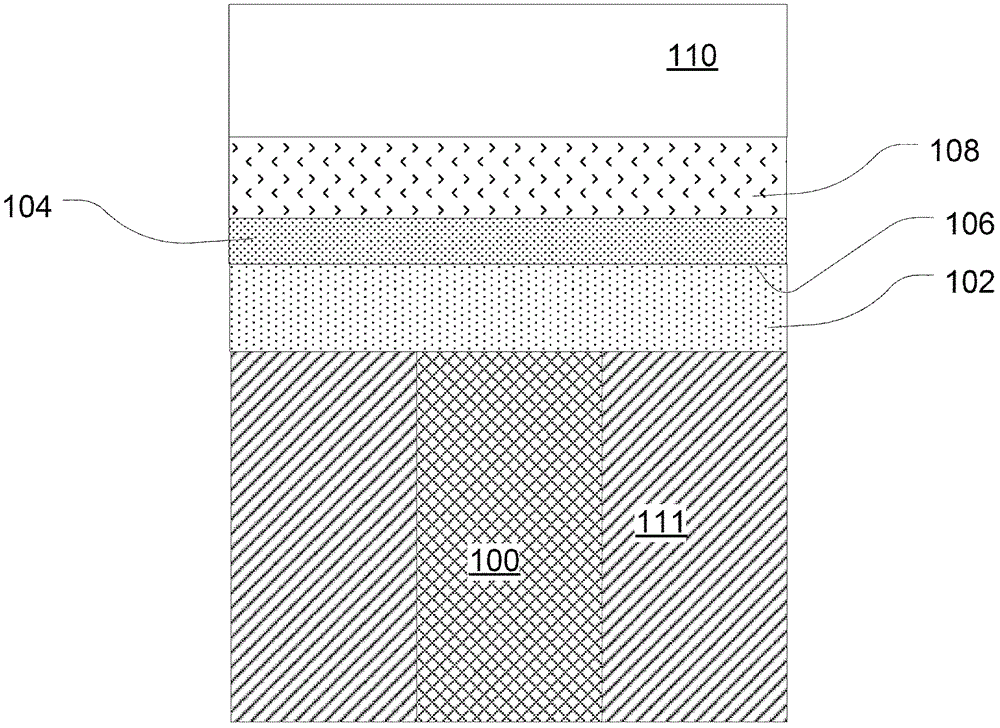

[0066] figure 1 A cross-sectional view of a programmable metallization unit with two dielectric layers according to an embodiment of the invention is shown. The programmable metallization unit includes a first electrode 100 , and in an embodiment, the first electrode 100 includes a plug located in a through hole of the interlayer dielectric 111 . The cell includes a first dielectric layer 102 overlying and in contact with a first electrode 100 . The second dielectric layer 104 is stacked on the first dielectric layer 102 and has an interface 106 at an intermediate distance between the first electrode 100 and the second electrode 110 . The first dielectric layer 102 and the second dielectric layer 104 may comprise any dielectric material suitable to allow the diffusion of conductive ions through these layers and to enable the generation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com