Light emitting diode and flip-chip light emitting diode package

一种发光二极管、封装组件的技术,应用在电气元件、半导体器件、电路等方向,能够解决减少发光二极管组件、热聚集、发光二极管发光面积减少等问题,达到电流分布均匀度提高、增加横向分布、提高发光效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

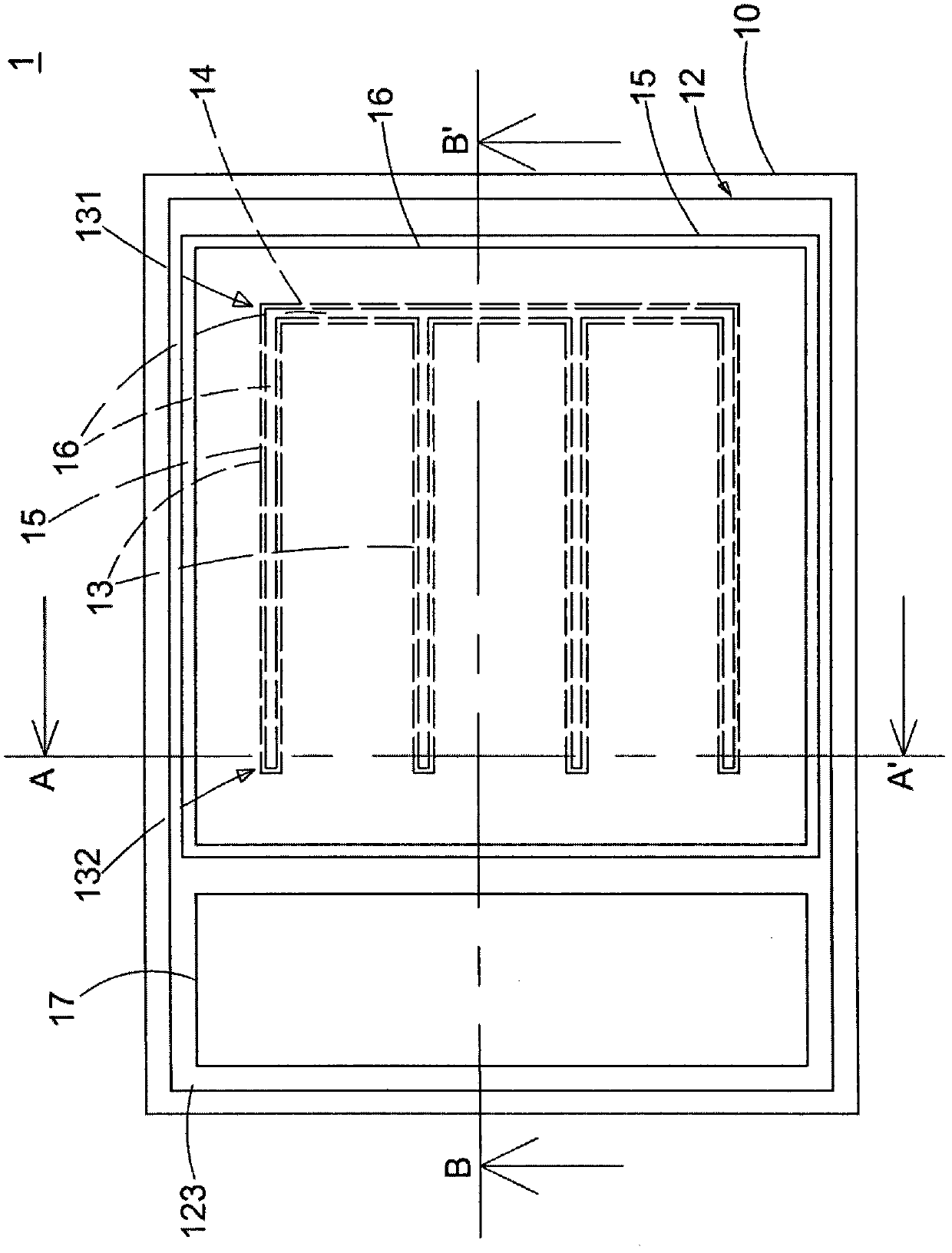

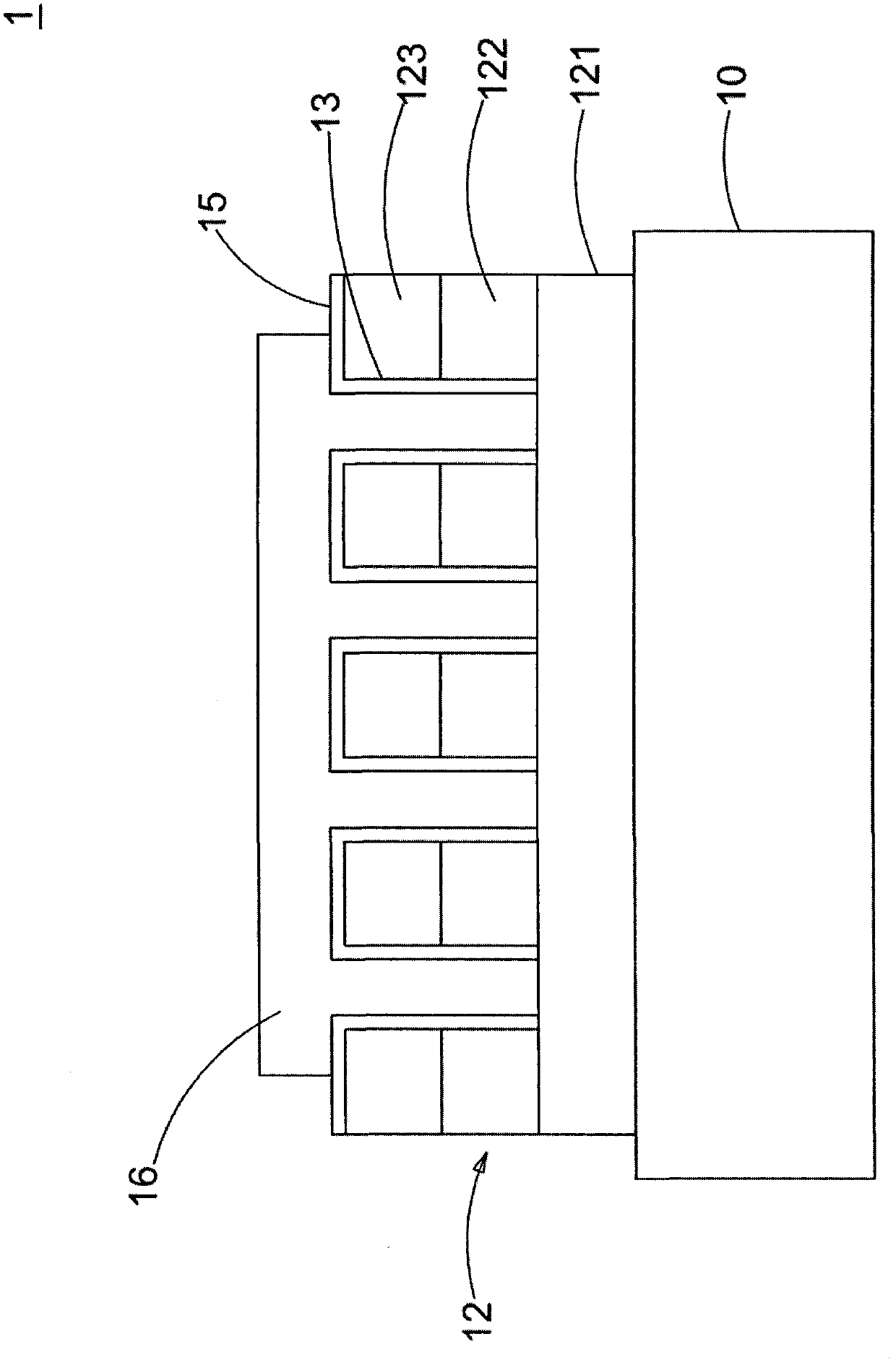

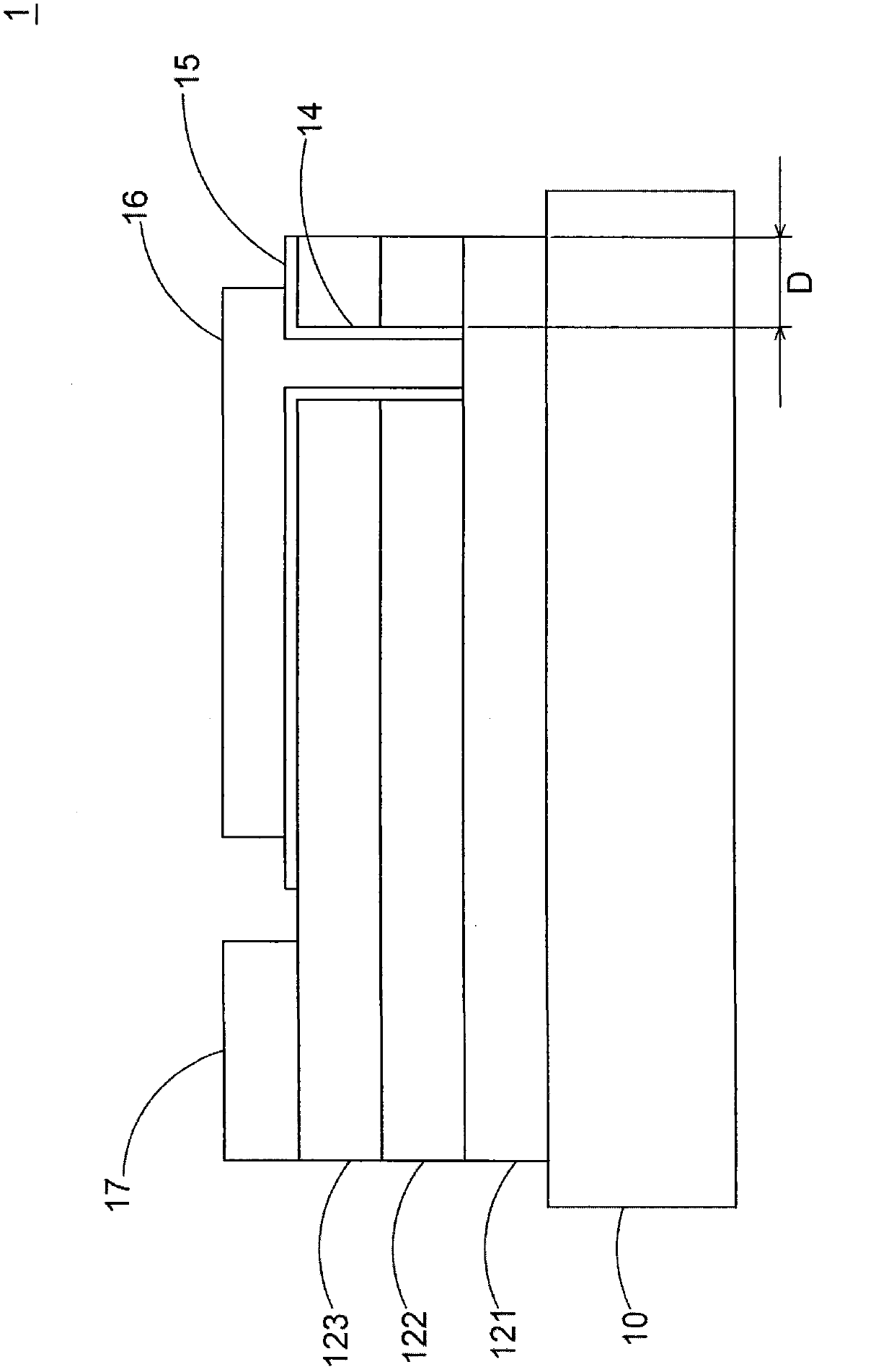

[0077] The present invention provides a light-emitting diode component, which includes: a component substrate; a first-type doped layer configured on the component substrate; a light-emitting layer configured on the first-type doped layer; a first-type doped layer The second-type doped layer, which is arranged on the light-emitting layer; a plurality of first grooves, which penetrate the second-type doped layer and the light-emitting layer and expose part of the surface of the first-type doped layer, each of which The first ditch has a first end and a second end; a second ditch is connected in series with the first ends of the first ditch, and the extending direction of the second ditch is different from that of the first ditch. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com