Lead screw accuracy detector

A technology of precision detection and lead screw, applied in the field of precision detectors, can solve the problem of high cost and achieve the effect of low manufacturing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

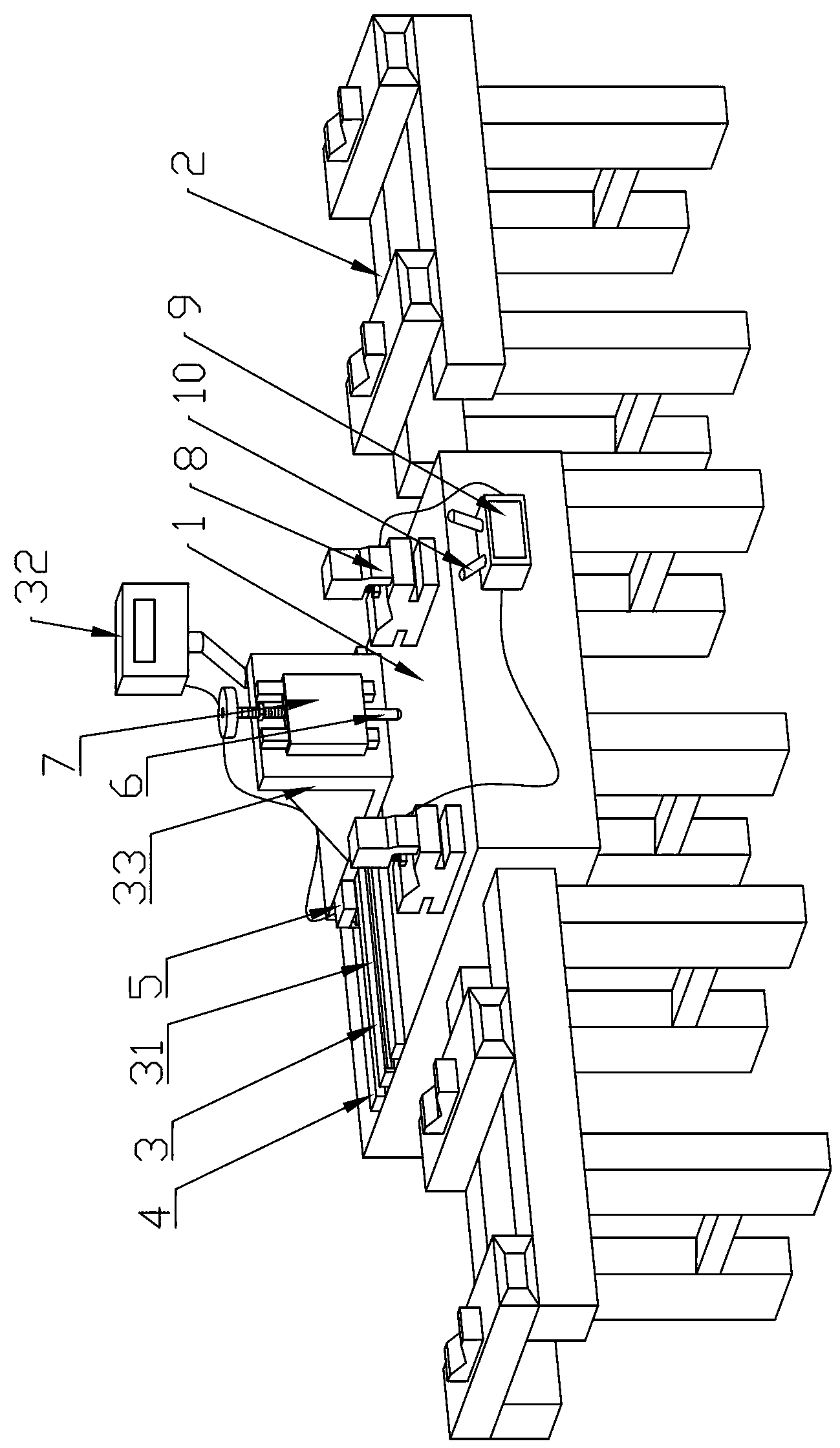

[0012] like figure 1 As shown, a lead screw accuracy detector of the present invention includes a detection platform 1 and a transverse support 2, a grating detection device 3 for detecting the accuracy of the lead screw is arranged above the detection platform 1, and there are two transverse supports 2, respectively It is symmetrically arranged on both sides of the detection platform 1 .

[0013] The grating detection device 3 includes a grating ruler 31, a grating data display 32, and a movable support 33. The grating ruler 31 is fixed on the detection platform 1 along its transverse and horizontal direction, and lateral guide rails are provided on both sides of the grating ruler 31. 4. The movable support 33 is fixed on the transverse guide rail 4 through the concave slider provided at the bottom, and a grating detector 5 is provided on one side of the movable support 33 close to the grating scale 31, and the grating detects The device 5 is connected to the grating data di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com