An Exhaust Pipe Structure for Eliminating Welding Stress

A welding stress, exhaust pipe technology, applied in the direction of exhaust device, muffler device, engine components, etc., can solve the problems of exhaust pipe failure, welding port fracture, abnormal sound of exhaust pipe, etc., to avoid abnormal sound, eliminate abnormal noise, etc. Welding stress, the effect of low retrofit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

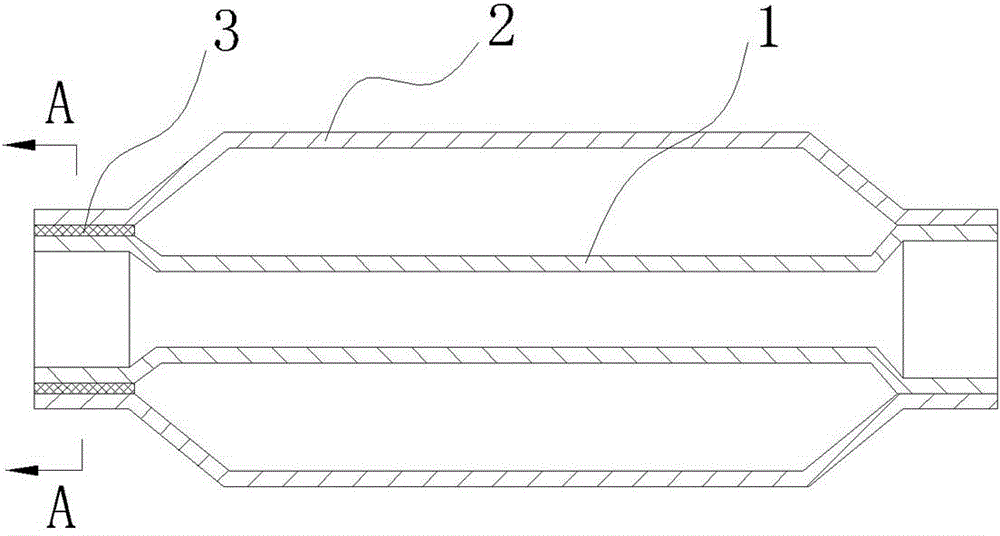

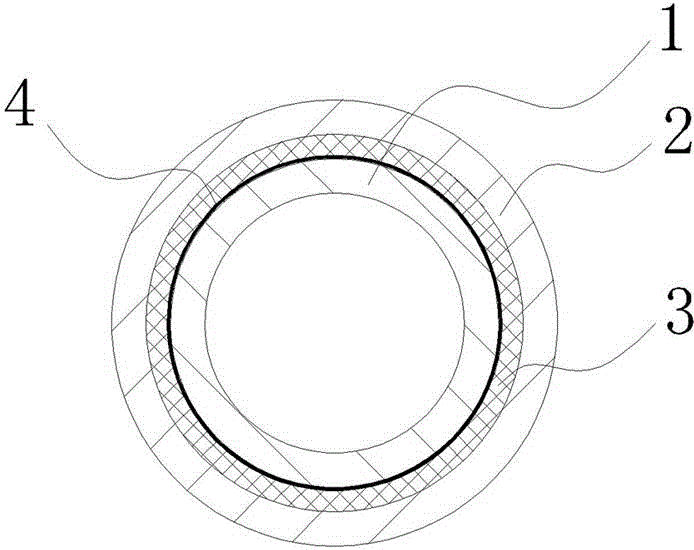

[0016] Such as figure 1 As shown, an exhaust pipe structure for eliminating welding stress of the present invention includes an inner cylinder 1 and an outer cylinder 2 coaxially shrouded outside the inner cylinder 1, and the inner cylinder 1 and the outer cylinder 2. The gas ends are fixed together by welding, such as figure 2 As shown, a grid-shaped friction layer 4 is rolled and formed on the outer wall surface of the exhaust end of the inner cylinder 1, and an annular elastic member 3 is fitted on the outer wall surface of the inner cylinder 1 corresponding to the friction layer 4. The elastic member 3 is The sponge-like metal mesh is filled between the outer cylinder body 2 and the corresponding outer wall surface of the inner cylinder body 1 , so that the exhaust end of the inner cylinder body 1 is elastically supported in the outer cylinder body 2 through the elastic member 3 .

[0017] When the vehicle is driving in a cold region, the inner cylinder 1 expands and bec...

Embodiment 2

[0019] The elastic member 3 is a high-temperature-resistant rubber pad, and the remaining parts are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com