A mung bean protein peptide having ACE inhibitory activity and a preparation method and applications thereof

A mung bean protein and activity-inhibiting technology, which is applied in the field of high value-added deep processing and utilization of agricultural by-products, can solve the problems of retention, low product efficacy, unfavorable end product development, etc., and achieve the advantages of promoting centrifugal separation, facilitating protein sedimentation, and significant biological activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

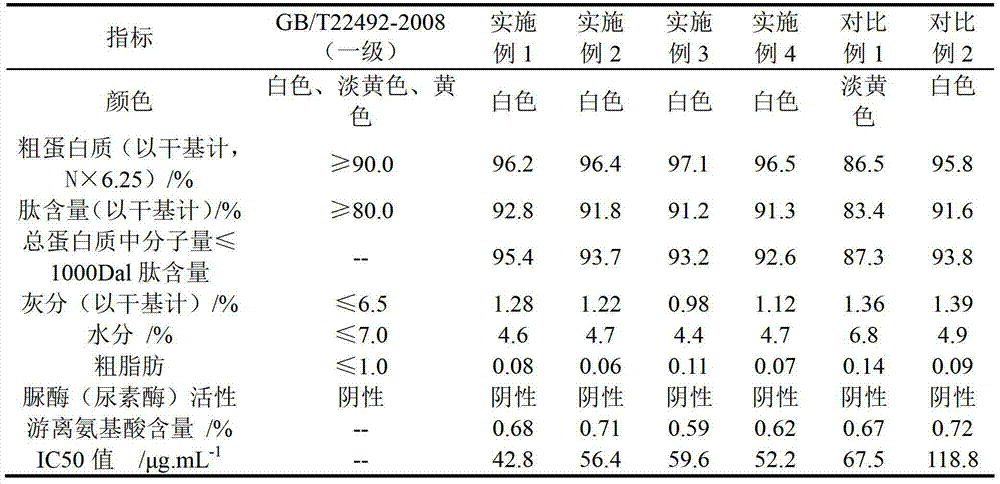

Examples

Embodiment 1

[0053] (1) Dispersion and dissolution of mung bean protein powder: Mung bean protein powder (64.8% protein content, 9.6% moisture content, the same below) was prepared as mung bean protein slurry with 45°C deionized water equivalent to 10 times the mass of mung bean protein powder, The slurry was dispersed and mixed for 20 min at a shear rate of 2000 rpm.

[0054] (2) Cellulase enzymatic hydrolysis and enzyme inactivation: adjust the pH value of the mung bean protein slurry dispersed and mixed in step (1) to 4.0 with a hydrochloric acid solution with a concentration of 3 mol / L, and add fiber equivalent to 0.5% of the mass of mung bean protein powder Suzyme (Type B, Guangzhou Yulibao Biotechnology Co., Ltd., the same below), after 1.5h of enzymolysis at 45°C with constant temperature stirring (speed 36rpm), the temperature was raised to 90°C for 15min to inactivate the enzyme.

[0055] (3) Centrifugal separation, washing with water to remove impurities: cool the mung bean prote...

Embodiment 2

[0061] (1) Dispersion and dissolution of mung bean protein powder: Prepare mung bean protein powder with 55°C deionized water equivalent to 6 times the mass of mung bean protein powder into mung bean protein slurry, and disperse and mix the slurry for 10 minutes at a shear speed of 3000 rpm.

[0062] (2) Cellulase enzymatic hydrolysis and enzyme inactivation: adjust the pH value of the mung bean protein slurry dispersed and mixed in step (1) to 3.5 with a hydrochloric acid solution with a concentration of 4mol / L, and add fiber equivalent to 1% of the mass of mung bean protein powder Sulfase, after enzymolysis at 55°C with constant temperature stirring (36rpm speed) for 1 hour, the temperature was raised to 85°C and kept for 20 minutes to inactivate the enzyme.

[0063] (3) Centrifugal separation, washing with water to remove impurities: cool the mung bean protein slurry after the enzyme inactivation in step (2) to below 65°C, centrifuge at 6000rpm for 10min, and take the precip...

Embodiment 3

[0069] (1) Dispersion and dissolution of mung bean protein powder: prepare mung bean protein powder with 50°C deionized water equivalent to 8 times the mass of mung bean protein powder into a mung bean protein slurry, and disperse and mix the slurry for 15 minutes at a shear speed of 2400 rpm.

[0070] (2) Cellulase enzymatic hydrolysis and enzyme inactivation: adjust the pH value of the mung bean protein slurry dispersed and mixed in step (1) to 4.5 with a hydrochloric acid solution with a concentration of 1mol / L, and add fiber equivalent to 0.1% of the mass of mung bean protein powder Sulfase, after enzymolysis at 50°C with constant temperature stirring (36rpm speed) for 2h, the temperature was raised to 100°C and kept for 10min to inactivate the enzyme.

[0071] (3) Centrifugal separation, washing with water to remove impurities: cool the mung bean protein slurry after the enzyme inactivation in step (2) to below 65°C, centrifuge at 5000rpm for 15min, and take the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com