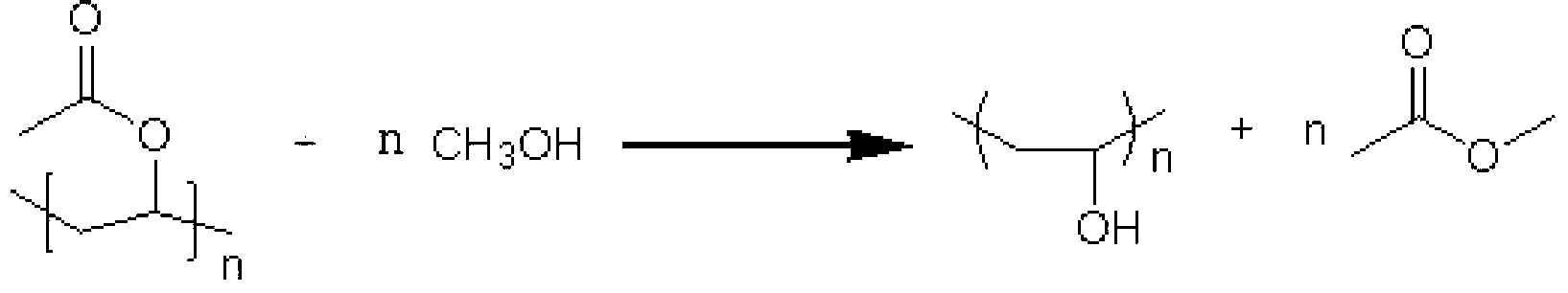

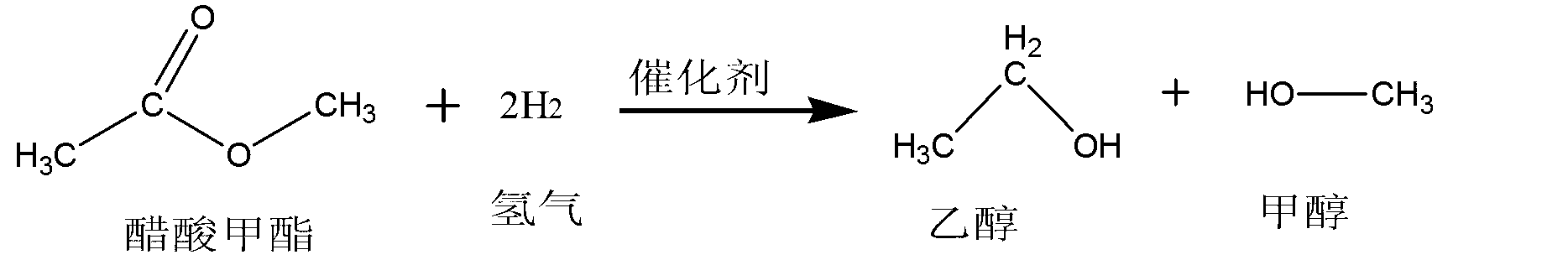

Method for preparing methanol and ethanol by methyl acetate by way of hydrogenation

A technology for the preparation of methyl acetate and hydrogen, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low catalyst conversion rate, low product selectivity, and high reaction temperature, and achieves improved reaction conversion. High efficiency, high selectivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

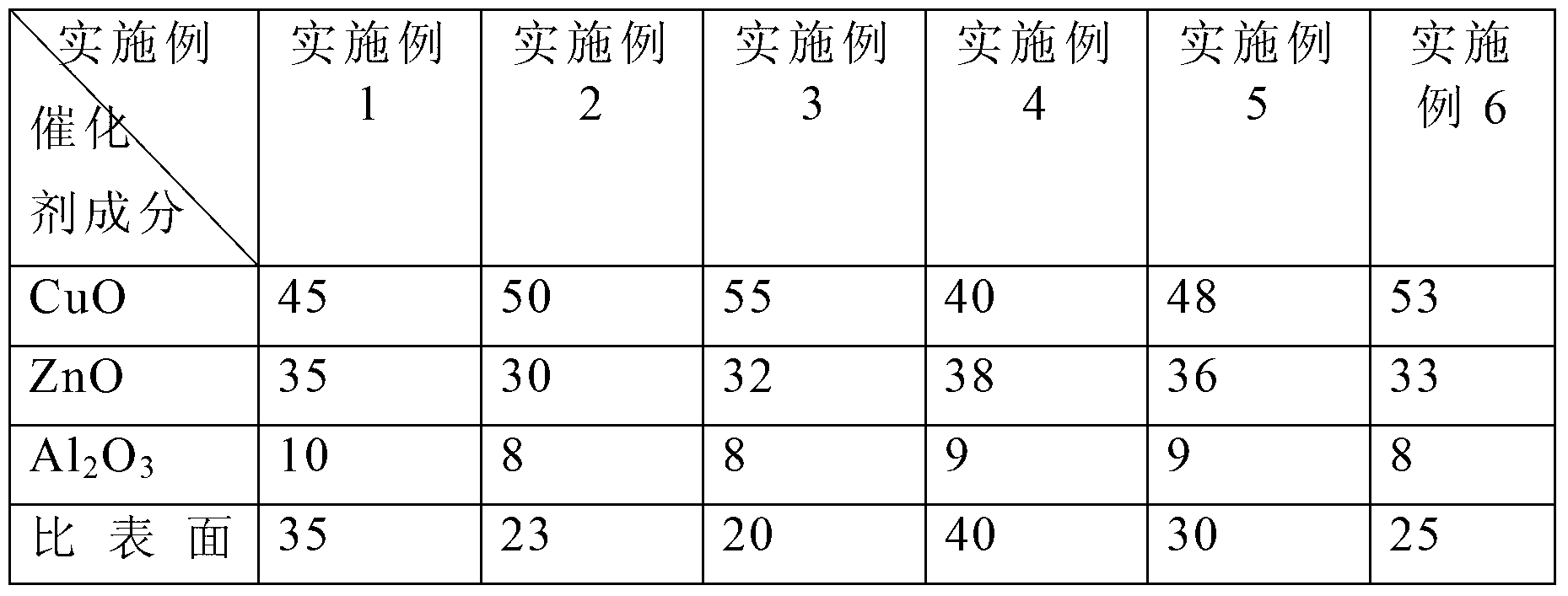

Embodiment 1

[0030] 740g purity is that the by-product methyl acetate of the preparation polyvinyl alcohol of 60% is pumped in the high-pressure reactor by high-pressure pump, after gasification, by the catalyzer in the good 10g table 1 embodiment 1 of activation in advance, in catalyst bed In the layer, the hydrogenation reduction reaction is carried out under the conditions of a space velocity of 1.5h-1, a hydrogen-ester ratio of 30:1, a reaction temperature of 220°C, and a system pressure of 2.0MPa, and then cooled to obtain 770g of a reaction solution. Distilled methanol and ethanol. The conversion rate of the reaction is 99%, the selectivity is 98.5%, and the product content is above 99.5%.

Embodiment 2

[0032] 1480g purity is that the by-product methyl acetate of the preparation polyvinyl alcohol of 50% is pumped in the high-pressure reactor by high-pressure pump, after gasification, by the catalyzer in the embodiment 2 of 10g table 1 activated in advance, in the catalyst bed In the process, the hydrogenation reduction reaction was carried out under the conditions of a space velocity of 1.5h-1, a hydrogen-ester ratio of 30:1, a reaction temperature of 230°C, and a system pressure of 2.5MPa, and then cooled to obtain 1550g of reaction liquid, which was distilled Methanol and ethanol are obtained. The conversion rate of the reaction is 98.7%, the selectivity is 98.8%, and the product content is above 99.5%.

Embodiment 3

[0034] 2960g purity is the by-product methyl acetate of the preparation polyvinyl alcohol of 80% and is pumped in the high-pressure reactor by high-pressure pump, after gasification, by the catalyzer in the embodiment 3 of 10g table 1 activated in advance, in the catalyst bed , at an airspeed of 1.3h-1 , Hydrogen-ester ratio is 30:1, reaction temperature is 245°C, system pressure is 2.8MPa for hydrogenation reduction reaction, then cooled to obtain 3110g reaction liquid, and the reaction liquid is distilled to obtain methanol and ethanol. The reaction conversion rate is 99.5%, the selectivity is 99%, and the product content is above 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com