Industrial circulation water quick sterilization technology and system

An industrial circulating water and rapid technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of not having continuous sterilization function, not having the ability to inhibit bacterial regeneration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

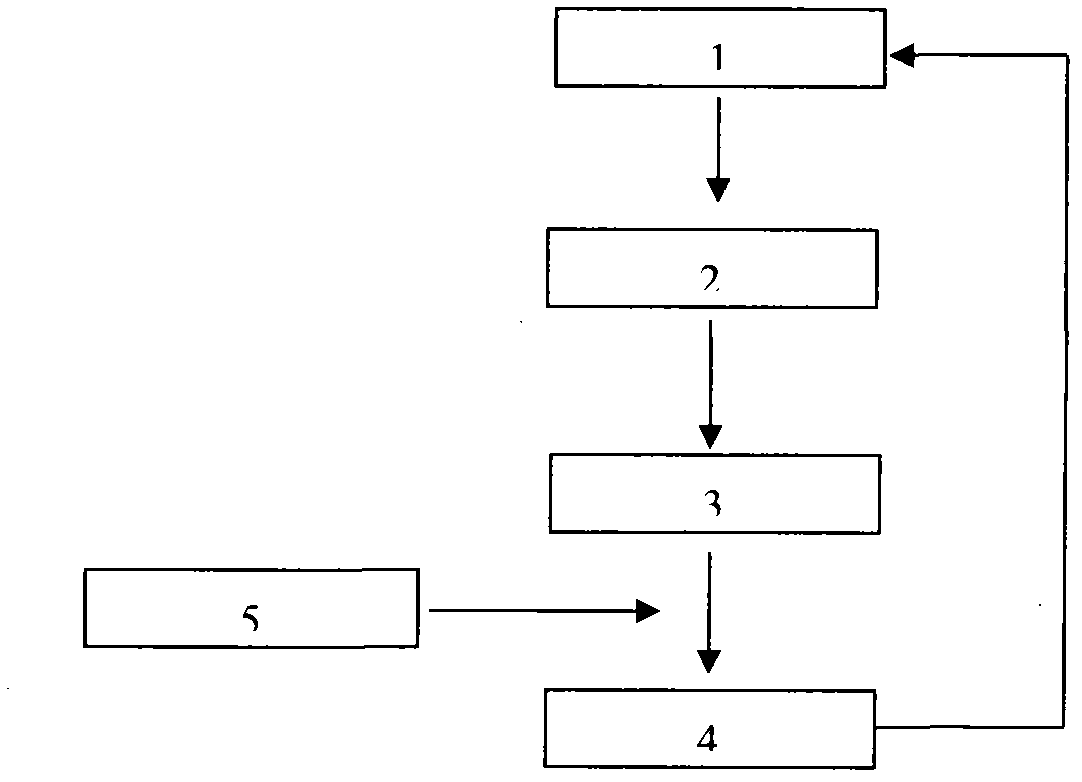

[0008] exist figure 1 In the process, the circulating water enters the cooling tower (2) from the heat exchange device (1), and then undergoes rapid sterilization treatment through the ultraviolet sterilizing device (3), and a trace chemical bactericide (4) is added to the circulating water after the ultraviolet sterilizing treatment, Afterwards, the circulating water is sent to the heat exchange device with the circulation pump (5), so that the circulation continues, and the ultraviolet sterilizing device constantly kills the bacteria that the circulating water incorporates from the outside and the bacteria that are regenerated inside during the circulation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com