High-fiber coarse cereal flour and preparation method of the high-fiber coarse cereal flour

A multi-grain, high-fiber technology, applied in the preparation of multi-grain high-fiber flour, in the field of multi-grain high-fiber flour, can solve the problems of different composition, structure and characteristics of multi-grain, restricting the research and development and production of multi-grain flour, and prone to rancidity, etc., so as to improve the taste. and processing properties, improve gluten-free protein content, and improve the effect of digestibility and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

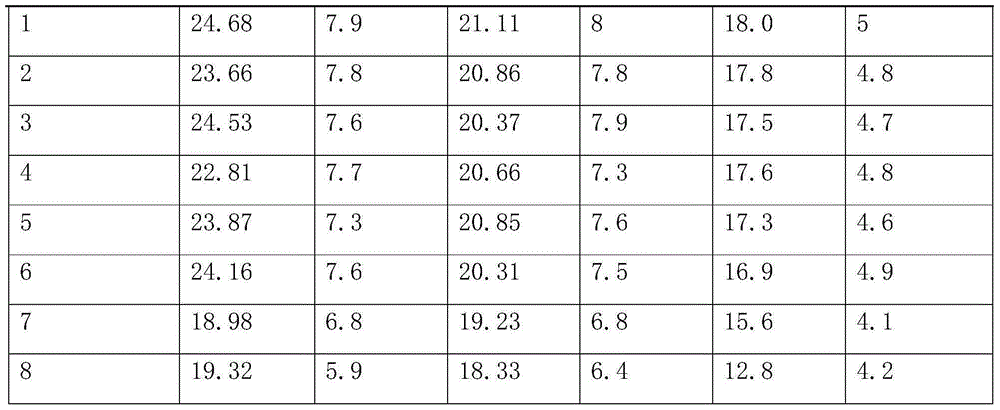

Examples

Embodiment 1

[0039] A miscellaneous grain high-fiber flour, comprising the following composition in parts by weight: high-gluten wheat flour: miscellaneous grain bran flour=7:1;

[0040] The mass fraction of the miscellaneous grain bran powder is: wheat bran powder: oat bran powder: corn flour=5:2:2;

[0041] The high-fiber flour with miscellaneous grains has the mixed smell of wheat and miscellaneous grains, and the taste is normal without peculiar smell;

[0042] The dietary fiber content of the miscellaneous grain high-fiber flour is not less than 6.0%, and the wet gluten content is 30-36%;

[0043] Ash content (on a dry basis), ≤2.80%;

[0044] Thickness, all through CQ14 sieve;

[0045] Other indicators are:

[0046] Sand content, ≤0.02%; magnetic metal objects, ≤0.003g / kg; moisture ≤13.5%; fatty acid value (calculated on a wet basis), mgKOH / 100g, ≤80;

[0047] The above percentage "%" is the mass percentage;

[0048] A method for preparing miscellaneous grain high-fiber flour, c...

Embodiment 2

[0063] A miscellaneous grain high-fiber flour comprises the following composition in parts by weight: high-gluten wheat flour: miscellaneous grain bran flour=9:1;

[0064] The mass fraction of the miscellaneous grain bran powder is: wheat bran powder: oat bran powder: corn flour=4:3:1;

[0065] The high-fiber flour with miscellaneous grains has the mixed smell of wheat and miscellaneous grains, and the taste is normal without peculiar smell;

[0066] The dietary fiber content of the miscellaneous grain high-fiber flour is not less than 6.0%, and the wet gluten content is 32-36%;

[0067] Ash content (on a dry basis), ≤2.80%;

[0068] Thickness, all through CQ14 sieve;

[0069] Other indicators are:

[0070] Sand content, ≤0.02%; magnetic metal objects, ≤0.003g / kg; moisture ≤13.5%; fatty acid value (calculated on a wet basis), mgKOH / 100g, ≤80;

[0071] The above percentage "%" is the mass percentage;

[0072] A method for preparing miscellaneous grain high-fiber flour, com...

Embodiment 3

[0087] A miscellaneous grain high-fiber flour, comprising the following composition in parts by weight: high-gluten wheat flour: miscellaneous grain bran flour=7:3;

[0088] The miscellaneous grain bran powder is wheat bran powder and oat bran powder, and the ratio of wheat bran powder and oat bran powder is not limited;

[0089] The high-fiber flour with miscellaneous grains has the mixed smell of wheat and miscellaneous grains, and the taste is normal without peculiar smell;

[0090] The dietary fiber content of the miscellaneous grain high-fiber flour is not less than 6.0%, and the wet gluten content is 30-32%;

[0091] Ash content (on a dry basis), ≤2.80%;

[0092] Thickness, all through CQ14 sieve;

[0093] Other indicators are:

[0094] Sand content, ≤0.02%; magnetic metal objects, ≤0.003g / kg; moisture ≤13.5%; fatty acid value (calculated on a wet basis), mgKOH / 100g, ≤80;

[0095] The above percentage "%" is the mass percentage;

[0096] A method for preparing misce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com