Narrow gap laser hot-wire-filling welding process for 316LN thick plate

A hot wire welding and narrow gap technology, which is applied in the field of narrow gap laser filling hot wire welding technology, can solve the problems of aggravating thermal deformation, thermal cracks, and affecting the performance of welded joints, achieving good detection results, small heat input, The effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

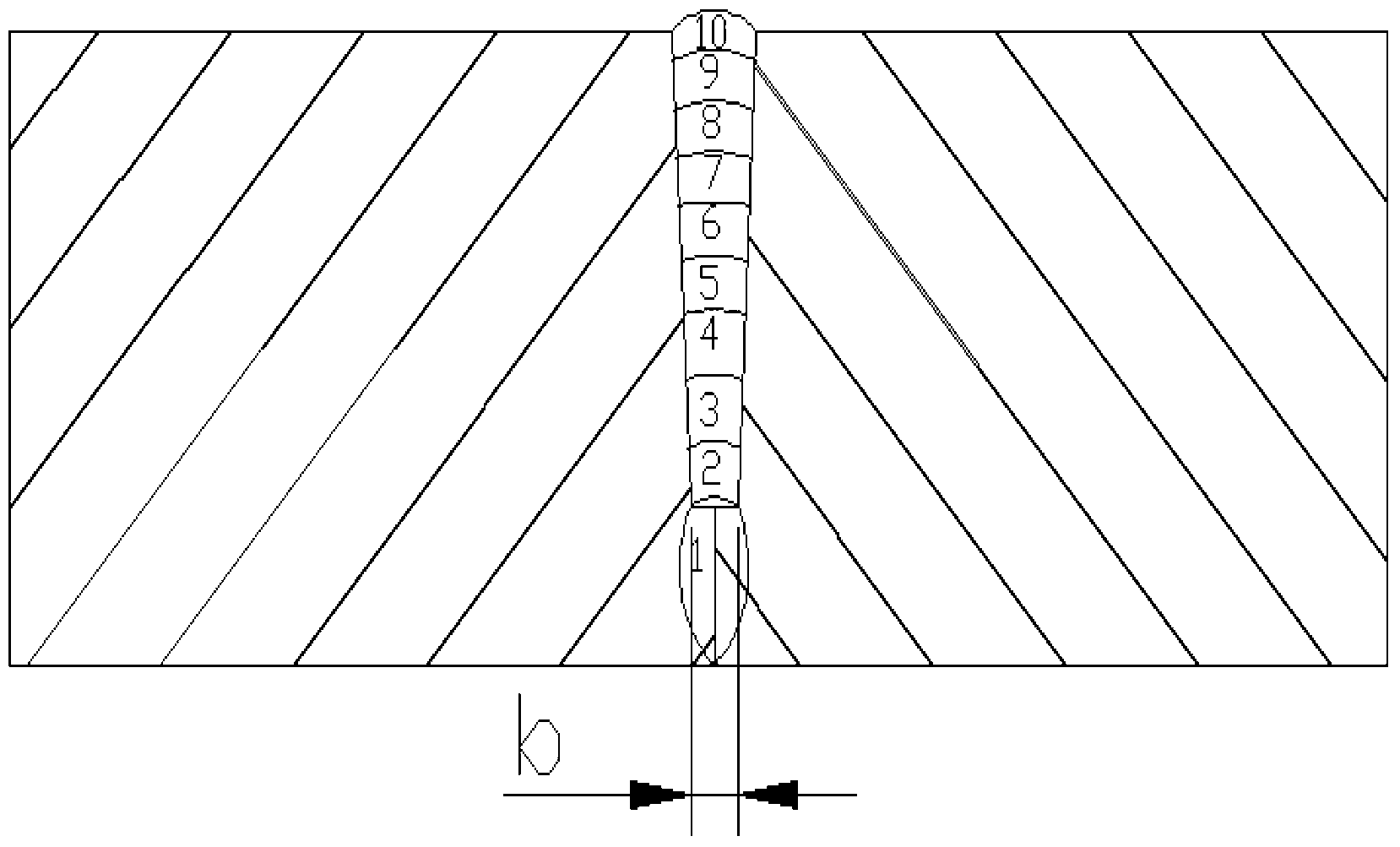

[0016] Carry out butt welding of a pair of 316LN plates with a thickness of 20mm, a length of 300mm and a width of 150mm, see figure 1 . The groove angle is 6°, the blunt edge depth is 5mm, and b=2mm.

[0017] Press the test plate first figure 1 The group is good, the specific number of welding layers distribution see figure 1 .

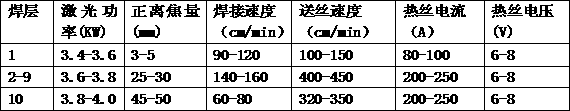

[0018] The welding parameters used in the welding process are shown in Table 1:

[0019] Table 1 Welding parameter list

[0020]

[0021] The wire feed angle is 40°±2°, and the laser beam angle is 7°-10° from the vertical direction.

[0022] After welding, the test plate was tested according to the ISO 15614-11 standard and the B-level level in ISO13919-1, and the non-destructive testing was all qualified. Take 4 side bending specimens, 3 impact specimens, grain size evaluation, and 2 tensile specimens. There is no crack in side bending at 180°; weld seam and heat-affected zone -196°C, impact absorption capacity ≥ 107J; grain size grade is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com