Hot rolling method of metallurgical bonding wear-resistant composite tube

A technology of metallurgical combination and composite pipe, which is applied in the field of pipe rolling, can solve problems such as rolling and warping, and achieve the effects of avoiding rolling, improving as-cast structure, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

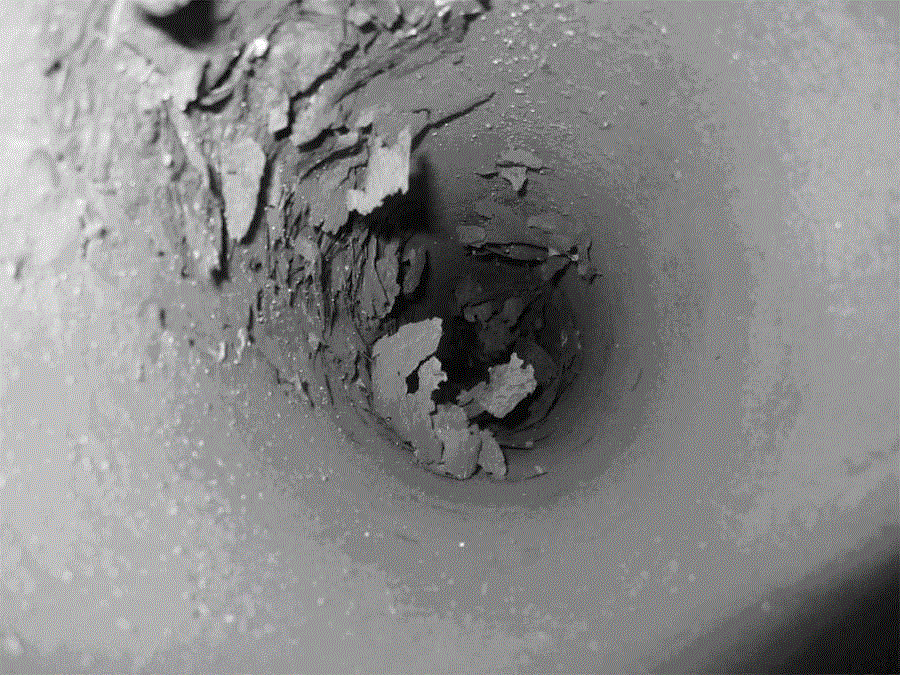

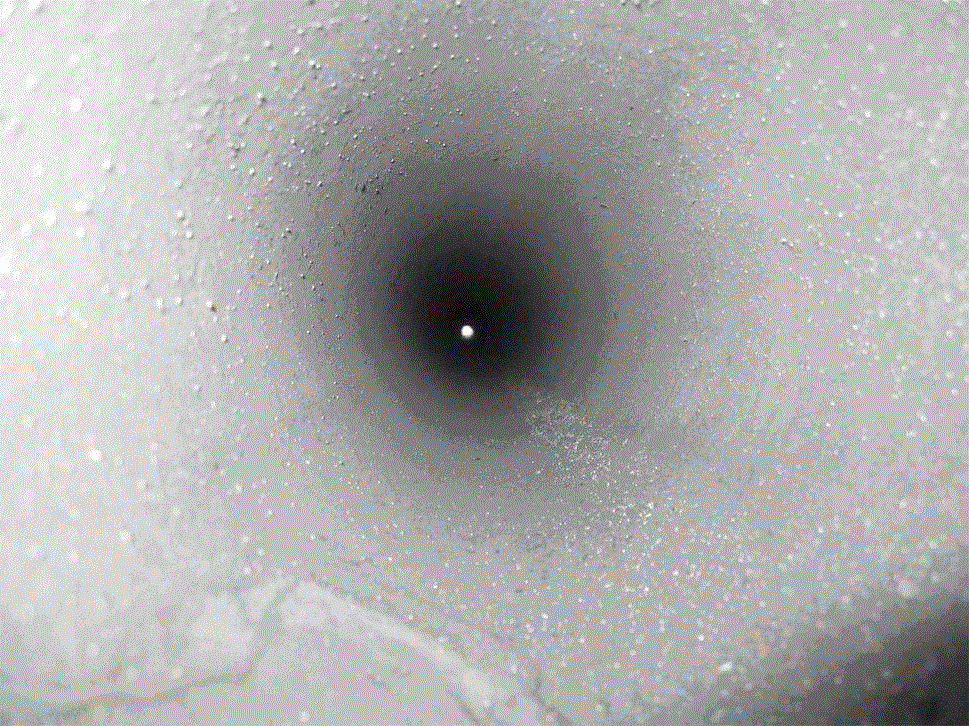

Image

Examples

Embodiment 1

[0024] The material of the composite pipe in this embodiment is: the outer layer is 20# low-carbon steel, the inner layer is GCr15 high-carbon steel, and the target product specification is φ133mm*5.5mm (outer layer 2mm+inner layer 3.5mm).

[0025] Utilize the concrete steps of the present invention to produce this product as follows:

[0026] In the first step, the centrifugal casting process is used to cast the outer layer alloy first, and then the inner layer alloy to prepare a centrifugal billet of the metallurgical bonded wear-resistant composite pipe.

[0027] The second step is to anneal the centrifugal billet obtained in the first step.

[0028] In the third step, the outer wall of the centrifuge blank obtained in the second step is processed by 4 mm on one side, and the inner wall is processed by 4 mm on one side. The purpose of the single side processing is to remove bad tissue parts on the outer wall and the inner wall.

[0029] The fourth step is to uniformly heat...

Embodiment 2

[0035] The material of the composite pipe in this embodiment is: the outer layer is 15Mn, the inner layer is GCr15SiMn, and the target product specification is φ140mm*9mm (outer layer 3.5mm+inner layer 5.5mm).

[0036] The concrete steps of utilizing this product of the present invention are as follows:

[0037] In the first step, the centrifugal casting process is used to cast the outer layer alloy first, and then the inner layer alloy to prepare a centrifugal billet of the metallurgical bonded wear-resistant composite pipe.

[0038] The second step is to anneal the centrifugal billet obtained in the first step.

[0039] In the third step, the outer wall of the centrifuge blank obtained in the second step is unilaterally processed by 6 mm, and the inner wall is unilaterally processed by 5 mm. The purpose of unilateral processing is to remove bad tissue parts on the outer wall and the inner wall.

[0040] The fourth step is to uniformly heat the centrifuge blank processed in ...

Embodiment 3

[0045] The composite pipe material is: the outer layer is 20Mn, the inner layer is GCr18Mo, and the target product specification is φ159mm*8.5mm (outer layer 3.5mm+inner layer 5mm).

[0046] Utilize the concrete steps of the present invention to produce this product as follows:

[0047] In the first step, the centrifugal casting process is used to cast the outer layer alloy first, and then the inner layer alloy to prepare a centrifugal billet of the metallurgical bonded wear-resistant composite pipe.

[0048] The second step is to anneal the centrifugal billet obtained in the first step.

[0049] In the third step, the outer wall of the centrifugal blank obtained in the second step is processed by 5mm on one side, and the inner wall is processed by 7mm on one side. The purpose of the single-side processing is to remove bad tissue parts on the outer wall and the inner wall.

[0050] The fourth step is to uniformly heat the centrifuge blank processed in the third step to 1200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com