Tobacco leaf level type loosening and moisture regaining method

A kind of loose moisture regain, graded technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of large moisture content and temperature fluctuations of export materials, large differences in chemical and chemical characteristics, and increased shrinkage rate, etc. The effect of sweet and moist air, maintaining the aroma of tobacco leaves, and removing impurities in tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

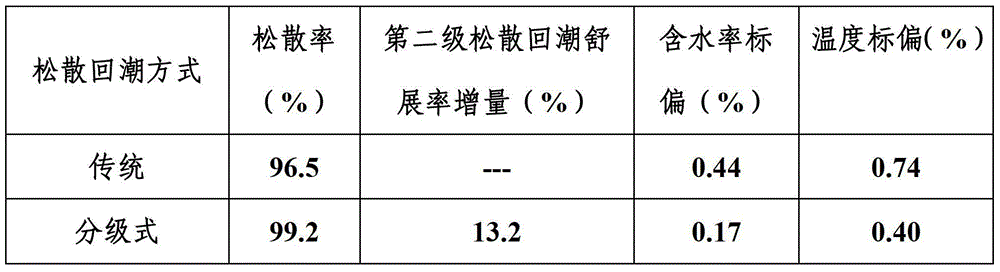

[0018] In the Kunming Cigarette Factory of Hongyun Honghe Group, the leaf group module of Yunyan (soft treasure) brand cigarettes is subjected to a hierarchical loosening and moisture regaining treatment with a processing intensity of high in the front and low in the back (see process figure 1 ), the temperature of the process hot air used in the first stage of loosening and regaining moisture is 64°C, the proportion of water added is 4%, the moisture content of the material outlet is 17.5%, and the temperature of the material outlet is 60°C; the temperature of the process hot air used in the second stage of loosening and regaining is 60°C , the proportion of water added is 1.8%, the moisture content of the material outlet is 19.0%, and the temperature of the material outlet is 58°C. After the tobacco leaves are processed, they are temporarily stored in the storage cabinet for 90 minutes.

[0019] Comparing the processing effect of traditional loose resurgence and graded loose ...

Embodiment 2

[0026] In the Kunming Cigarette Factory of Hongyun Honghe Group, the leaf group module of Yunyan (Purple) brand cigarettes is processed with a step-by-step loosening and regaining treatment (see process) figure 1 ), the temperature of the process hot air used in the first stage of loosening and regaining moisture is 67°C, the proportion of water added is 3.5%, the moisture content of the material outlet is 17%, and the temperature of the material outlet is 64°C; the temperature of the process hot air used in the second stage of loosening and regaining is 58°C , the proportion of water added is 1.2%, the moisture content of the material outlet is 19.0%, and the temperature of the material outlet is 57°C. After the tobacco leaves are processed, they are temporarily stored in the storage cabinet for 60 minutes.

[0027] Comparing the processing effect of traditional loose moisture regain and graded loose moisture regain, the test results of physical indicators are shown in Table 3...

Embodiment 3

[0034] In the Kunming Cigarette Factory of Hongyun Honghe Group, the leaf group module of Yunyan (5mg Impression) brand cigarettes is subjected to a hierarchical loosening and moisture regaining treatment with a processing intensity of low in the front and high in the back (see process) figure 1 ), the temperature of the process hot air used in the first stage of loosening and regaining moisture is 59°C, the proportion of water added is 3.8%, the moisture content of the material outlet is 17.5%, and the temperature of the material outlet is 57°C; the temperature of the process hot air used in the second stage of loosening and regaining is 63°C , the proportion of water added is 1.5%, the moisture content of the material outlet is 19.5%, and the temperature of the material outlet is 60°C. After the tobacco leaves are processed, they are temporarily stored in the storage cabinet for 120 minutes.

[0035] Comparing the processing effect of traditional loose moisture regain and gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com