Operation method of self-positioning robot-based multi-camera parameter automatic calibration system

A technology of automatic calibration system and operation method, which is applied in the field of multi-camera parameter automatic calibration system operation, can solve problems such as huge workload and error-prone, and achieve the effects of low cost, convenient upgrade, and large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

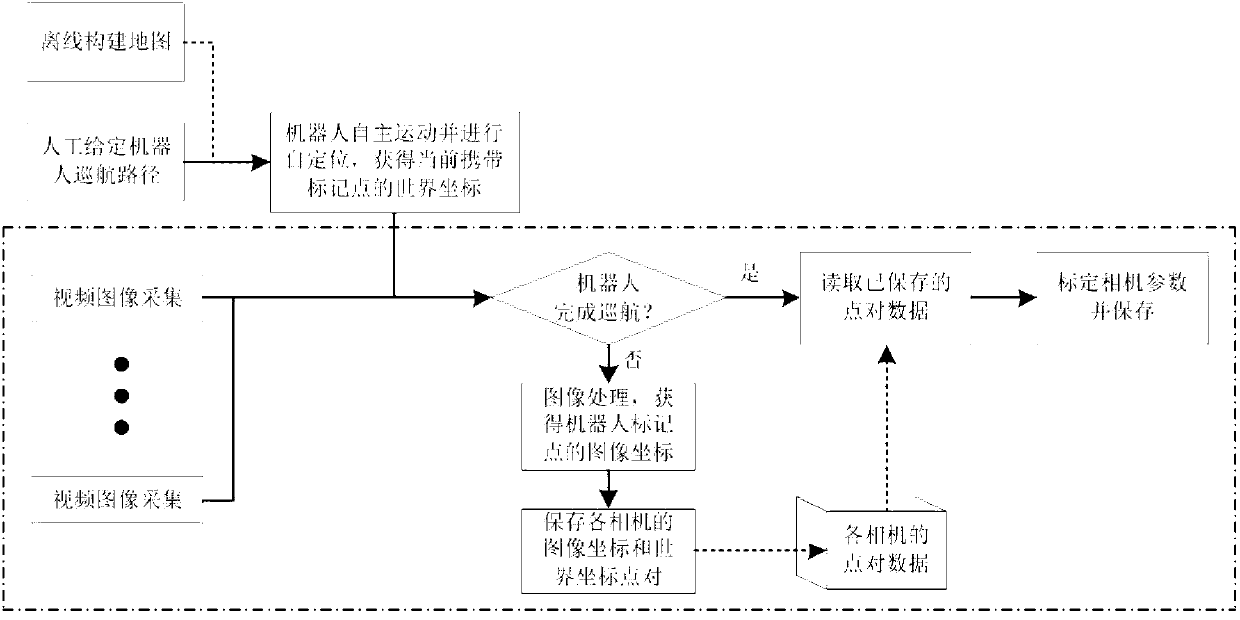

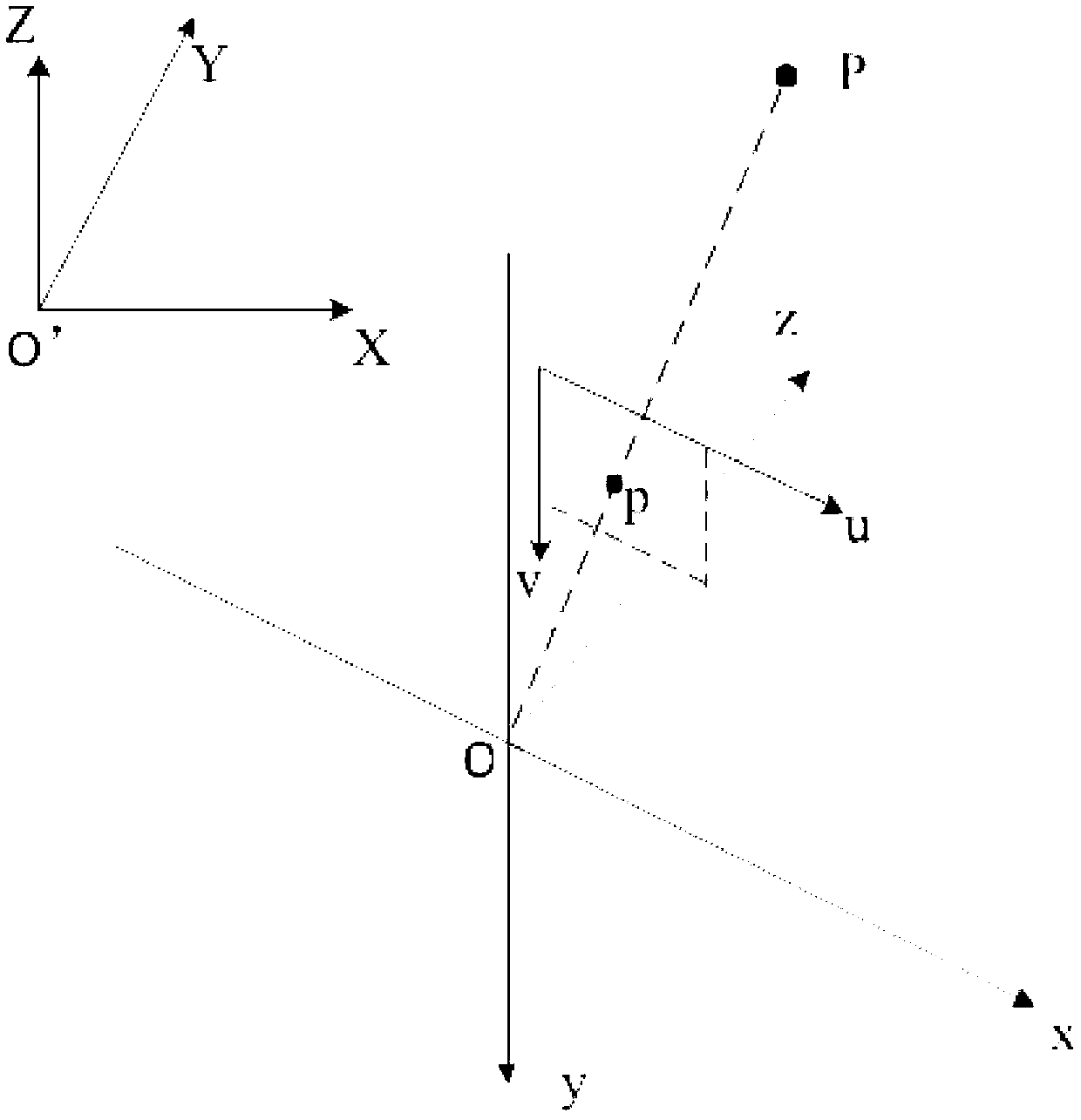

[0031] The following describes in detail the process of automatic calibration of internal and external parameters and distortion parameters of a fixed camera by combining the self-positioning results of the calibration robot with image processing results in the present invention in conjunction with the accompanying drawings.

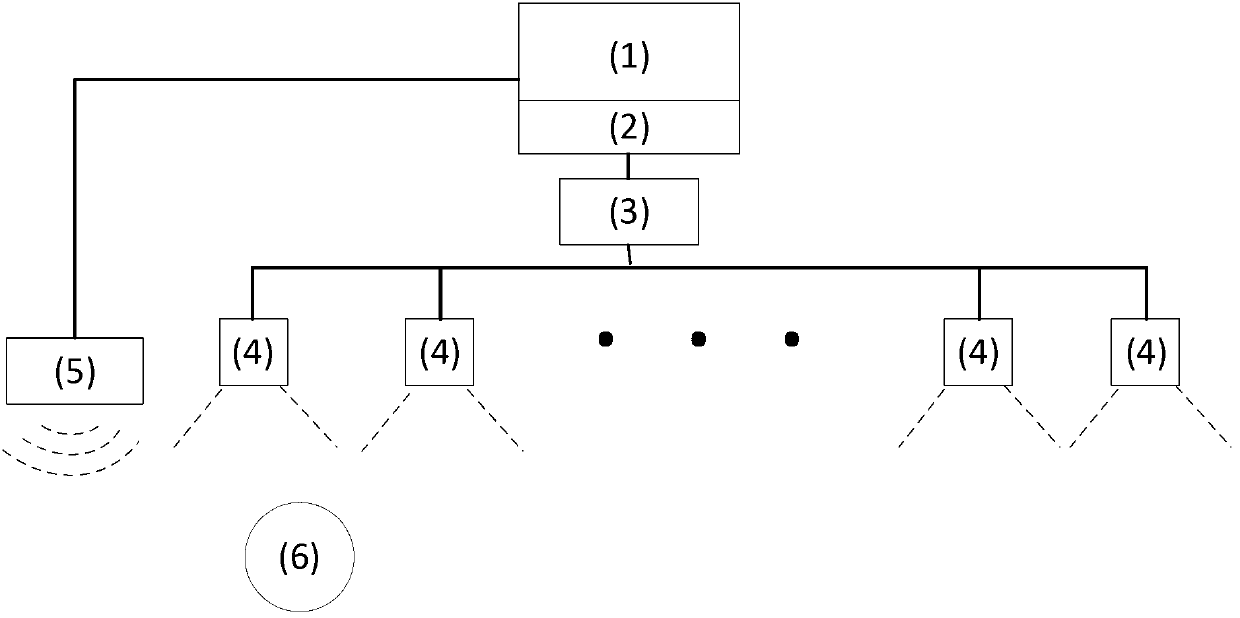

[0032] Such as figure 1 , 2 As shown, the steps of the operation method of the multi-camera parameter automatic calibration system based on the self-positioning robot are as follows

[0033] 1) Build a multi-camera parameter automatic calibration system based on a self-positioning robot, which includes a main control machine 1, a visual software operating system environment 2, camera video acquisition equipment 3, multiple cameras 4, wireless network communication equipment 5, and a self-positioning robot 6 A plurality of cameras 4 are connected with the main control machine 1 through the video acquisition device 3, and the video image acquisition and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com