A method and device for realizing a vacuum high-precision window

A realization method and high-precision technology, applied in installation, optics, instruments, etc., can solve the problem of low surface shape accuracy, and achieve the effect of improving surface shape accuracy, simple structure, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

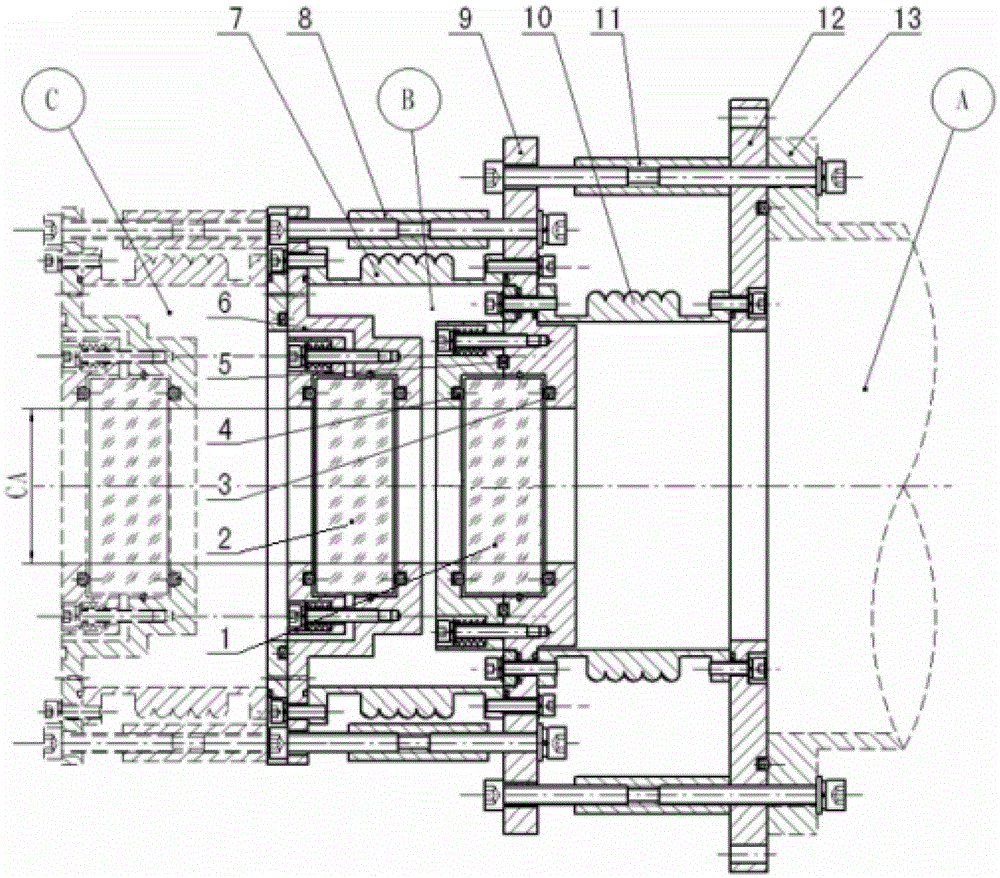

[0027] Embodiment 1: A method for realizing a vacuum high-precision window includes the following steps:

[0028] Step 1: using n pieces of window glass to form an optical window, and the n pieces of window glass are arranged horizontally and sequentially so that a closed cavity is formed between each adjacent two pieces of glass;

[0029] Step 2: vacuumize the multiple closed cavities formed in Step 1;

[0030] Step 3: Fill dry nitrogen into the multiple closed cavities that have been evacuated in step 2, so that the pressure in the multiple closed cavities increases sequentially.

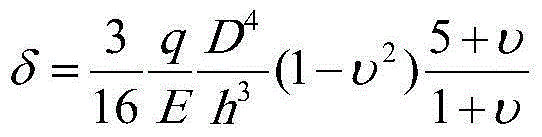

[0031] The pressure in the plurality of closed cavities described in step 3 is increased successively to specifically meet the following requirements: one side of the first piece of window glass in contact with the vacuum is a vacuum, and one side is 1 / n atmospheric pressure; one side of the second piece of window glass It is 1 / n atmospheric pressure, and one side is 2 / n atmospheric pressure... O...

Embodiment 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that neon gas is filled in a plurality of vacuumized closed cavities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com