A kind of elastomer composite mud discharging rubber hose and its production process

A production process and elastic body technology, applied in the field of mud discharge hose and its production process, can solve the problems of shortened service life, increased production cost, easy deformation of the pipe body, etc., achieve excellent wear resistance and improve bonding strength , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

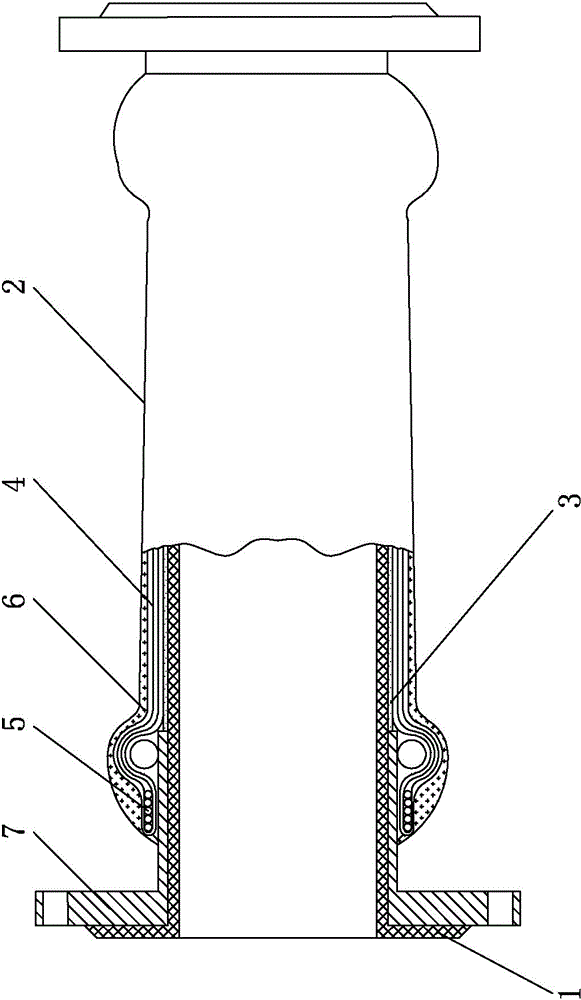

[0028] Such as figure 1 As shown, the middle layer 3 is set on the inner surface of the skeleton layer of the mud discharge hose 2, and the middle layer 3 is a canvas layer; the composite layer 1 is set on the inner surface of the middle layer 3 of the mud discharge hose, and the composite layer 1 is made of polyurethane material. Same size as existing mud hose. The cord layer, the tight steel wire, the outer layer of the rubber hose, and the short sleeve of the flange steel are the same as those of the prior art.

[0029] (1) Pipe embryo production: According to the thickness of the composite elastic body, design and determine the outer diameter of the forming mold for making the mud discharge hose; fix the flange steel short sleeve on the mud discharge hose forming mold and position it according to the design requirements. The middle canvas layer with single-sided rubber rubbing is wound between the blue steel short sleeves, and the rubberized side faces outward; the rubber...

Embodiment 2

[0032] Such as figure 1 As shown, the middle layer 3 is set on the inner surface of the skeleton layer of the mud discharge hose 2, and the middle layer 3 is a canvas layer; the composite layer 1 is set on the inner surface of the middle layer 3 of the mud discharge hose, and the composite layer 1 is made of polyurethane material. Same size as existing mud hose. The cord layer, the tight steel wire, the outer layer of the rubber hose, and the short sleeve of the flange steel are the same as those of the prior art.

[0033] (1) tube embryo production: same as embodiment 1;

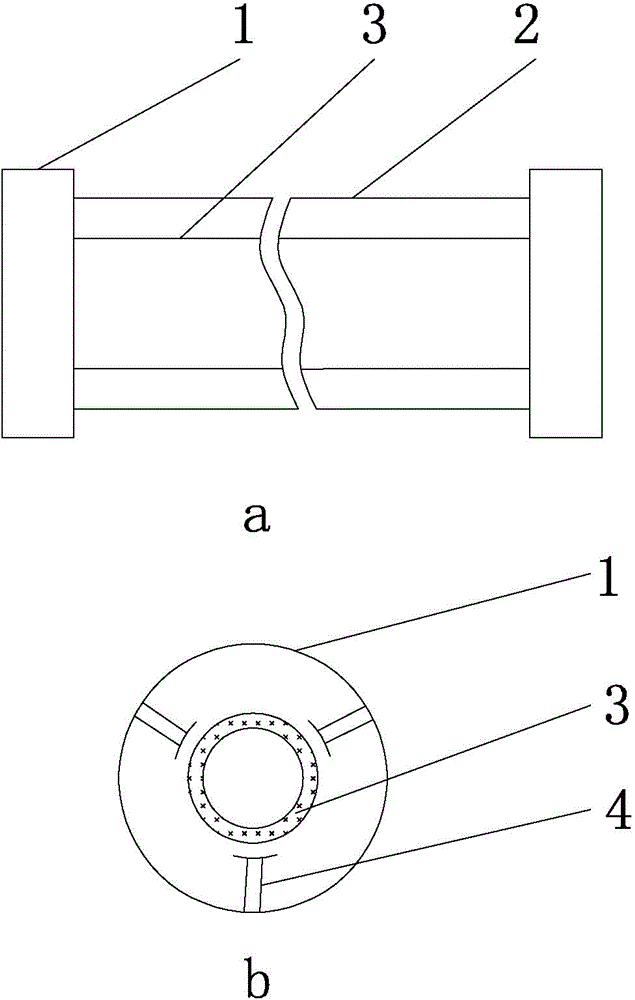

[0034] (2) Centrifugal forming: fix the prepared mud discharge hose embryo on the bracket (see figure 2 , the bracket is composed of 2 circular frames, and 3 length-adjustable fixed arms are uniformly arranged in each circular frame, the fixed arms are connected with the circular frame by bolts, and two adjacent circular frames are connected by iron bars) First, adjust the fixed arm of the bracket so th...

Embodiment 3

[0036] Such as figure 1 As shown, the middle layer 3 is set on the inner surface of the skeleton layer of the mud discharge hose 2, and the middle layer 3 is a canvas layer; the composite layer 1 is set on the inner surface of the middle layer 3 of the mud discharge hose, and the composite layer 1 is made of polyurethane material. Same size as existing mud hose. The cord layer, the tight steel wire, the outer layer of the rubber hose, and the short sleeve of the flange steel are the same as those of the prior art.

[0037] (1) tube embryo production: same as embodiment 1;

[0038] (2) Centrifugal forming: fix the prepared mud discharge hose embryo on the bracket (see figure 2 , the bracket is composed of 3 circular frames, and 3 fixed arms with adjustable length are uniformly arranged in each circular frame, the fixed arms and the circular frame are connected by bolts, and the adjacent two circular frames are connected by steel bars) First, adjust the fixed arm of the brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com