Installment structure of GRG decorative panel

A technology of installation structure and decorative panel, applied in the field of installation structure of GRG decorative panel, can solve the problems of lack of installation method of GRG decorative panel, restricting the promotion and application of GRG decorative panel, etc., so as to save workload, low installation cost and high installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

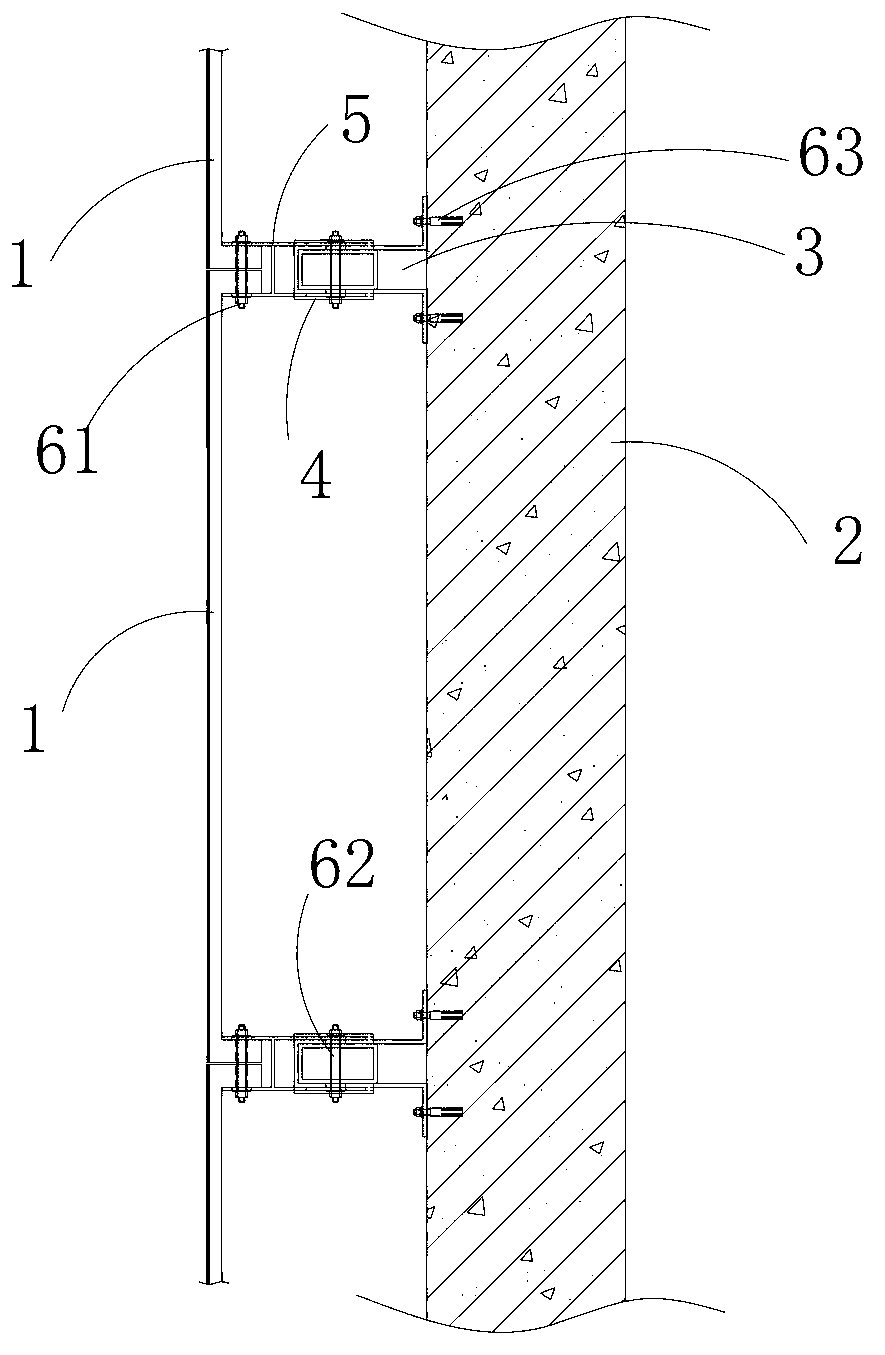

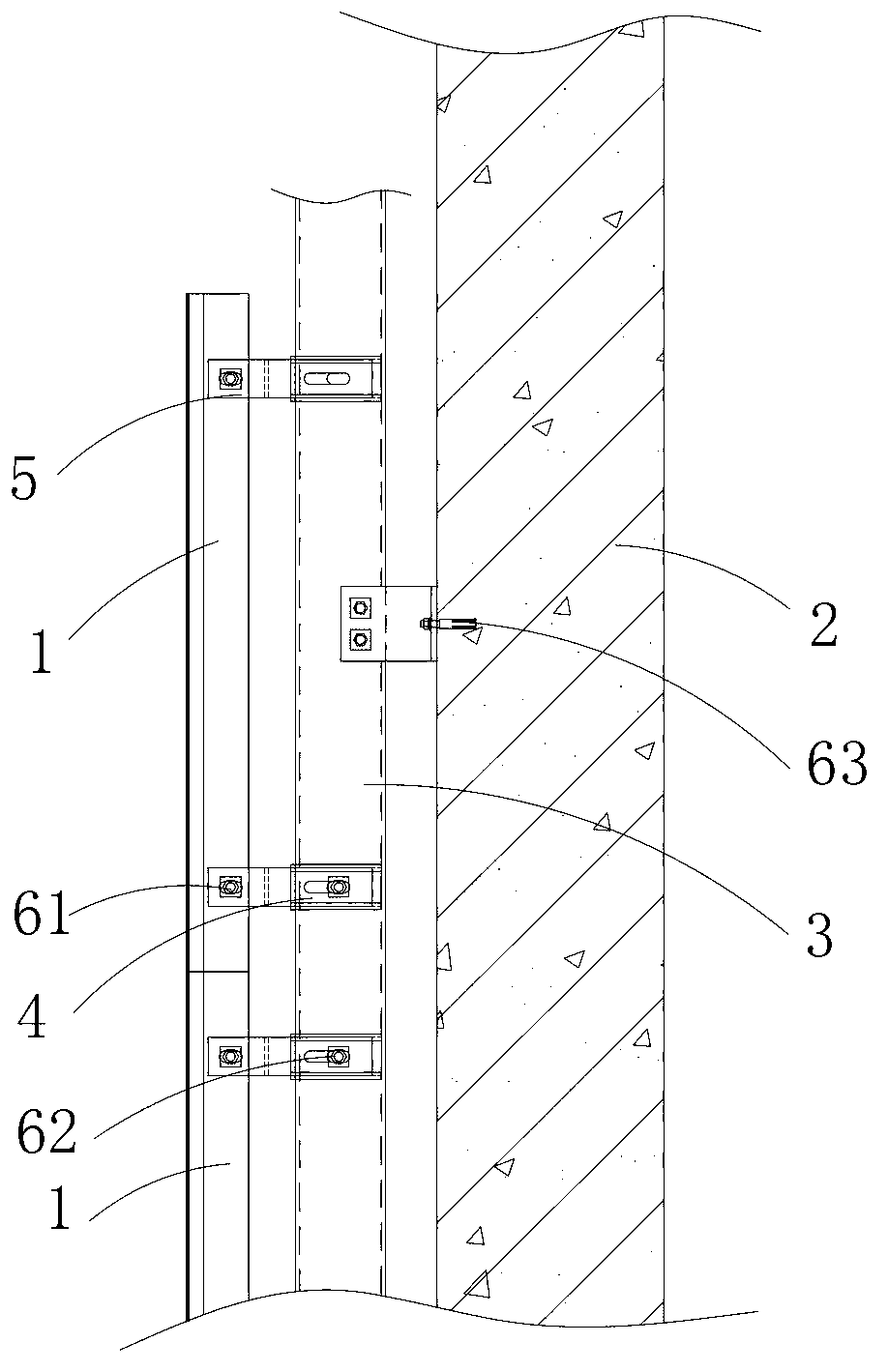

[0034] Such as figure 2 , 3 In the installation structure of the GRG veneer, the front side of the veneer 1 made of GRG material is a wood veneer, and the second mounting part 5 and the first mounting part 4 are fixed on the vertical keel 3, and the vertical keel 3 is fixed 2 surfaces on building walls. Each connecting piece adopts bolts. The second mounting part 5 and the first mounting part 4 are made of aluminum alloy or stainless steel.

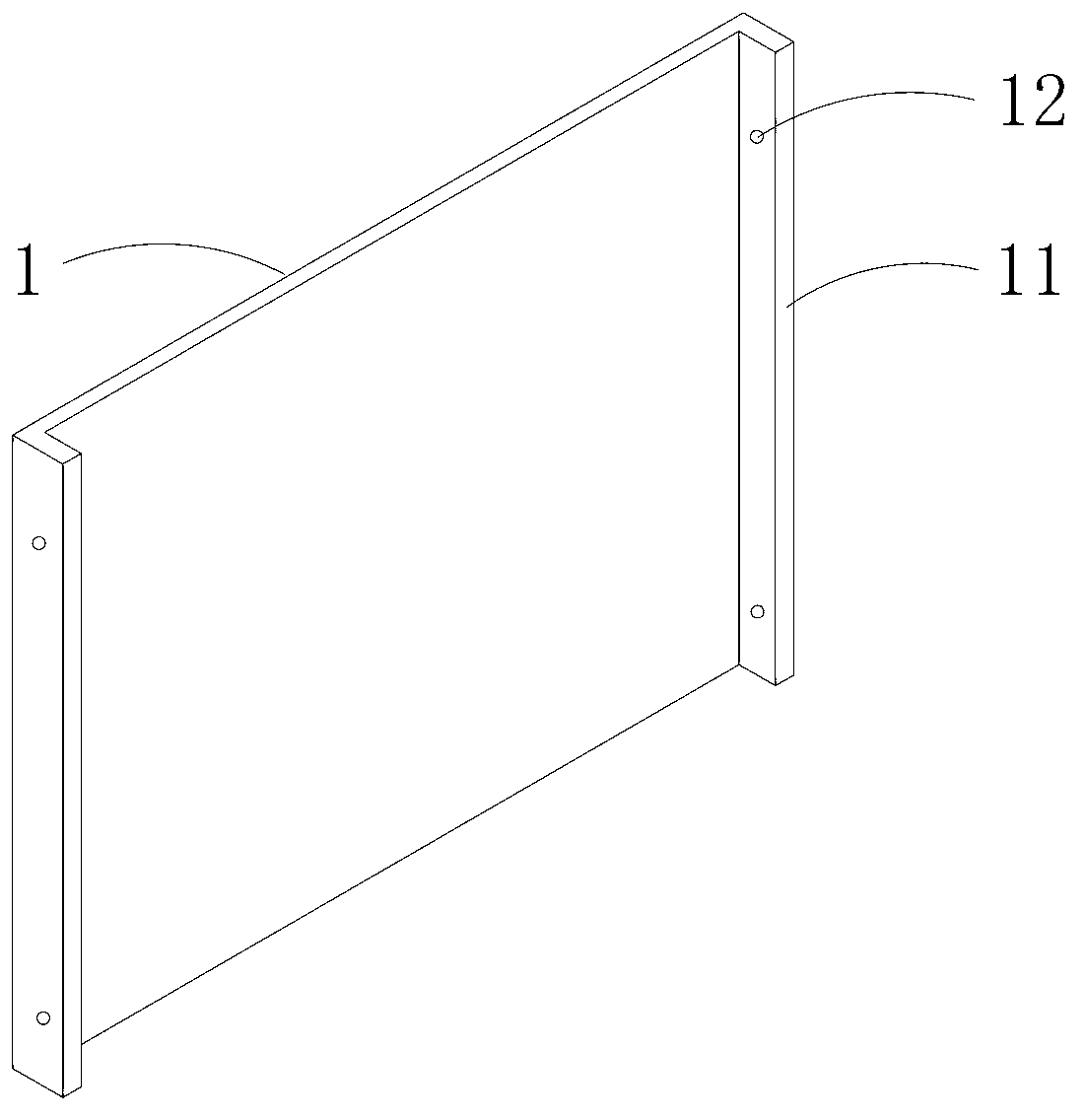

[0035] The veneer 1 is regularly arranged on the surface of the wall 2, such as figure 1 As shown, the structure is provided with vertical installation strips 11, and the vertical installation strips 11 are located on the left and right sides of the back of the GRG veneer 1. During production and processing, the sides of the GRG veneer are directly thickened and formed. A fourth fixing hole 12 through left and right is respectively opened on the upper part and the lower part of the vertical mounting bar 11 on each side.

[0036] The...

Embodiment 2

[0042] Such as Figure 9 , 10 The installation structure of the GRG veneer shown is different from that of Embodiment 1 in the following description.

[0043] Such as Figure 8 As shown, there is no fourth fixing hole 12 at the upper and lower ends of the vertical mounting strip 11 on the back of the GRG veneer 1, but an upper card slot 13 is provided on its upper side, and a lower card slot 14 is provided on the lower side.

[0044] Such as Figure 11 , 12 , 13, the left end of the second mounting part 5 is not provided with a third U-shaped opening 51, but is provided with an upper clamping plate 55 and a lower clamping plate 56; The lower clamping slot 14 of the upper decorative panel in the panel 1 and the lower clamping plate 56 are inserted into the upper clamping slot 13 of the lower decorative panel, thereby connecting and fixing the left end of the second mounting part 5 with two adjacent vertical mounting bars 11 . For the upper card slot of the highest GRG panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com