Preparation method of reinforced 6061aluminum matrix composite material

A technology of aluminum matrix composite material and aluminum alloy, which is applied in the field of 6061 aluminum matrix composite material preparation, can solve problems such as entanglement and agglomeration, reduction of length-to-diameter ratio, and magnesium borate whiskers cannot be completely uniformly dispersed, so as to achieve cost saving, Reduce the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention is a method for preparing a reinforced 6061 aluminum-based composite material, the steps of which are:

[0018] (1) According to the volume fraction of the total volume of the mixture of magnesium borate whiskers and 6061 aluminum alloy powder is 5%~20%, mix magnesium borate whiskers with 6061 aluminum alloy powder, put them into a ball mill for ball milling, and set the ball milling parameters as : The ball-to-material ratio is 10:1, the speed of the ball mill is 150r / min, the ball milling time is 10h, the working mode of the ball mill is forward rotation for 600s, stop for 60s, then reverse for 600s, stop for 60s, and so on;

[0019] (2) Put the ball-milled powder in the mold cavity and press it into a pre-compact at 100°C;

[0020] (3) Then heat slowly to 510°C for 30 minutes, and finally extrude uniformly at a speed of 10mm / s with an extrusion ratio of 9:1 to obtain a smooth-surfaced composite extruded rod. The outer wall is coated with a cert...

Embodiment 1

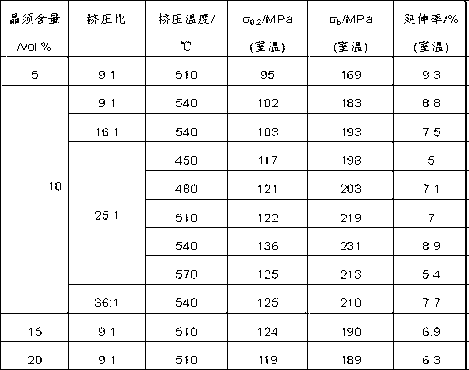

[0023] Put the magnesium borate whisker volume fraction of 15% and 85vol.% 6061 aluminum alloy powder mixture into a planetary ball mill for ball milling, with 65g in each can, and four cans in total. Set the ball mill parameters as follows: ball-to-material ratio 10:1, ball mill speed 150r / min, ball mill time 10h, ball mill working mode is forward rotation 600s, stop 60s, then reverse 600s, stop 60s, and so on. The ball-milled sample powder was placed in the mold cavity and pressed at 100°C to form a Φ60 mm pre-compact. Then slowly heat to 510°C and keep it warm for 30 minutes, and finally extrude uniformly at a speed of 10mm / s with an extrusion ratio of 9:1 to obtain a Φ20mm smooth composite extruded rod. Before extrusion, the inner and outer walls of the mold are uniform Apply a certain amount of lubricant. The measured room temperature mechanical properties of 15vol.% magnesium borate whisker reinforced 6061 aluminum matrix composites are: Vickers hardness HV=65.3, yield ...

Embodiment 2

[0025] Put the magnesium borate whisker volume fraction of 10% and 90vol.% 6061 aluminum alloy powder mixture into a planetary ball mill for ball milling, with 65g in each can, and four cans in total. Set the ball milling parameters as follows: the balls are Al2O3 balls, the ball-to-material ratio is 10:1, the speed of the ball mill is 150r / min, the milling time is 10h, the working mode of the ball mill is forward rotation for 600s, stop for 60s, then reverse for 600s, stop for 60s, and so on. . The ball-milled sample powder was placed in the mold cavity and pressed at 100°C to form a Φ60 mm pre-compact. Then slowly heat to 540°C for 30 minutes, and finally extrude uniformly at a speed of 10mm / s with an extrusion ratio of 25:1 to obtain a Φ12mm smooth composite extruded rod. Before extrusion, the inner and outer walls of the mold are uniform Apply a certain amount of lubricant. The measured room temperature mechanical properties of magnesium borate whisker reinforced 6061 al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength σ0.2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com