Glutamic acid synergistic ammonium bicarbonate fertilizer and production method thereof

A technology of ammonium bicarbonate and its production method, which can be applied to fertilizer mixtures, fertilization devices, applications, etc., and can solve the problems of high price and use of ammonium ion stabilizers, and the lack of further promotion of ammonium bicarbonate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

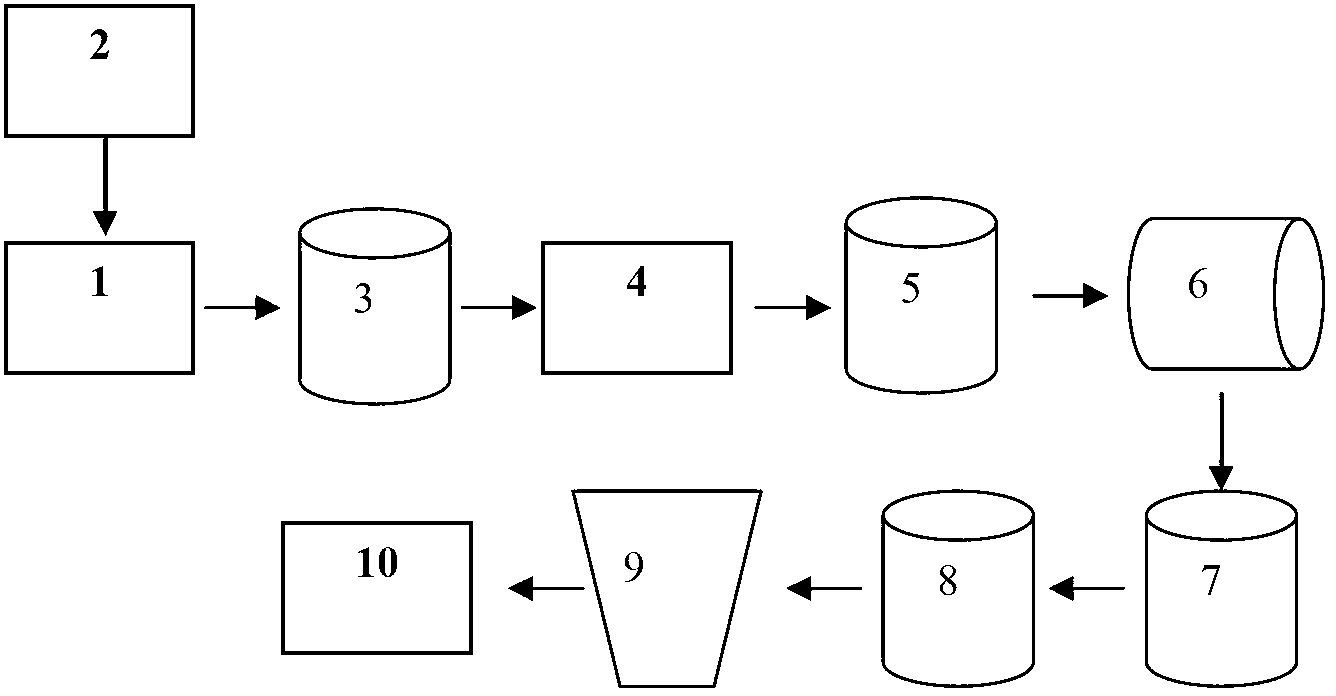

[0067] Embodiment 1: the production of glutamic acid synergistic ammonium bicarbonate fertilizer of the present invention

[0068] The implementation steps of this embodiment are as follows:

[0069] A. Preparation of glutamic acid synergistic solution:

[0070] Preparation concentration is 20% sodium glutamate solution by weight, and this solution is glutamic acid synergist solution A;

[0071] B. Production of glutamic acid synergistic ammonium bicarbonate

[0072] Add the glutamic acid synergist solution A and concentrated ammonia water prepared in step A into the concentrated ammonia water storage tank according to the weight ratio of 0.02:1, and stir evenly. The carbonization secondary tower and the carbonization main tower of the ammonium production process, in which the ammonia in the concentrated ammonia water reacts with carbon dioxide to generate ammonium bicarbonate; the generated ammonium bicarbonate then enters a thickener and a centrifuge for separation and dry...

Embodiment 2

[0075] Embodiment 2: the production of glutamic acid synergistic ammonium bicarbonate fertilizer of the present invention

[0076] The implementation steps of this embodiment are as follows:

[0077] A. Preparation of glutamic acid synergist solution:

[0078] Mix the concentration by weight of 10% sodium hydroxide solution and glutamic acid according to the weight ratio of 1.8:1, and the obtained solution is glutamic acid synergistic solution B;

[0079] B. Production of glutamic acid synergistic ammonium bicarbonate

[0080]Add the glutamic acid synergist solution B and concentrated ammonia water prepared in step A into the concentrated ammonia water storage tank according to the weight ratio of 0.10:1, and stir evenly. The carbonization secondary tower and the carbonization main tower of the ammonium production process, in which the ammonia in the concentrated ammonia water reacts with carbon dioxide to generate ammonium bicarbonate; the generated ammonium bicarbonate the...

Embodiment 3

[0083] Embodiment 3: the production of glutamic acid synergistic ammonium bicarbonate fertilizer of the present invention

[0084] The implementation steps of this embodiment are as follows:

[0085] A. Preparation of glutamic acid synergistic solution:

[0086] Preparation concentration is 10% sodium glutamate solution by weight, and this solution is glutamic acid synergist solution A;

[0087] B. Production of glutamic acid synergistic ammonium bicarbonate

[0088] Add the glutamic acid synergist solution A and concentrated ammonia water prepared in step A into the concentrated ammonia water storage tank according to the weight ratio of 0.04:1, and stir evenly. The carbonization secondary tower and the carbonization main tower of the ammonium production process, in which the ammonia in the concentrated ammonia water reacts with carbon dioxide to generate ammonium bicarbonate; the generated ammonium bicarbonate then enters a thickener and a centrifuge for separation and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com