Facing mortar

A technology of facing mortar and quartz sand, applied in the field of construction chemical materials, can solve the problems of high technical proficiency requirements of workers, increased construction costs, low work efficiency, etc., and achieves shortened construction time, excellent flexural strength, and low volatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

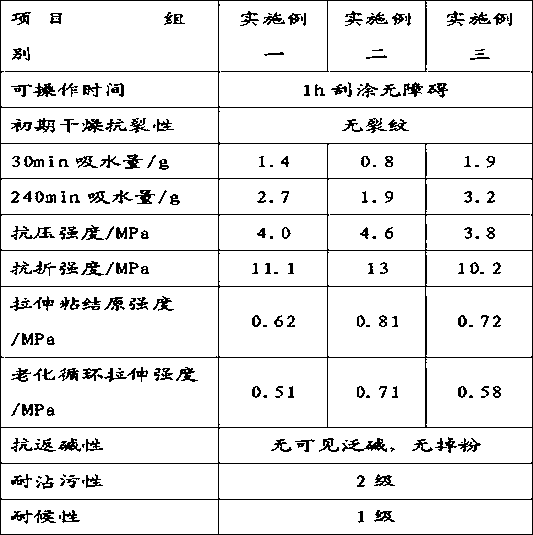

Embodiment 1

[0020] Embodiment 1: The facing mortar disclosed by the present invention, the facing mortar includes rubber powder, thickener, and quartz sand, and the mass percentages of each component in the facing mortar are respectively, rubber powder 10%, thickener 0.1 %, quartz sand 65%.

[0021] The rubber powder includes acrylic emulsion and anhydrous alumina, and the mass percentages of the acrylic emulsion and anhydrous alumina in the rubber powder are: 75-90% of acrylic emulsion and 10-25% of anhydrous alumina.

[0022] The above-mentioned acrylic emulsion acrylic emulsion includes methyl methacrylate, butyl acrylate, sodium lauryl sulfate, ammonium persulfate and sodium bicarbonate, and the mass percentage of each component in the acrylic emulsion is: methyl methacrylate 38.68%, Butyl acrylate 58.02%, sodium lauryl sulfate 2.5%, ammonium persulfate 0.5%, sodium bicarbonate 0.3%.

[0023] The fineness of the anhydrous alumina used for the rubber powder in the above-mentioned faci...

Embodiment 2

[0027] Embodiment 2: The formula of the facing mortar of the present invention includes rubber powder, a thickener, and quartz sand, and the mass percentages of each component in the facing mortar are respectively, rubber powder 8%, thickener 0.05%, quartz sand 91%.

[0028] The rubber powder includes acrylic emulsion and anhydrous alumina, and the mass percentages of the acrylic emulsion and anhydrous alumina in the rubber powder are: 75-90% of acrylic emulsion and 10-25% of anhydrous alumina.

[0029] The acrylic emulsion acrylic emulsion is obtained by mixing methyl methacrylate, butyl acrylate, sodium lauryl sulfate, ammonium persulfate and sodium bicarbonate, and the mass percentage of each component in the acrylic emulsion is: methyl methacrylate 38.68%, 58.02% butyl acrylate, 2.5% sodium lauryl sulfate, 0.5% ammonium persulfate, 0.3% sodium bicarbonate.

[0030] The fineness of the anhydrous alumina used for the rubber powder in the above-mentioned facing mortar is abo...

Embodiment 3

[0035] Embodiment three: the formula of facing mortar of the present invention comprises rubber powder, thickener, and quartz sand, and the mass percentages of each component in facing mortar are respectively, rubber powder 8%, thickener 0.08%, quartz sand 75%.

[0036] The rubber powder includes acrylic emulsion and anhydrous alumina, and the mass percentages of the acrylic emulsion and anhydrous alumina in the rubber powder are: 75-90% of acrylic emulsion and 10-25% of anhydrous alumina.

[0037] The acrylic emulsion acrylic emulsion is obtained by mixing methyl methacrylate, butyl acrylate, sodium lauryl sulfate, ammonium persulfate and sodium bicarbonate, and the mass percentage of each component in the acrylic emulsion is: methyl methacrylate 38.68%, 58.02% butyl acrylate, 2.5% sodium lauryl sulfate, 0.5% ammonium persulfate, 0.3% sodium bicarbonate.

[0038] The fineness of the anhydrous alumina used for the rubber powder in the above-mentioned facing mortar is above 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com