Novel polyvinyl chloride (PVC) mother solution treatment equipment and method

A technology for water treatment equipment and mother liquor, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high ozone unit cost, high system pollutant concentration, and ozone unit burden To ensure efficient removal rate, improve treatment efficiency, and ensure the effect of treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

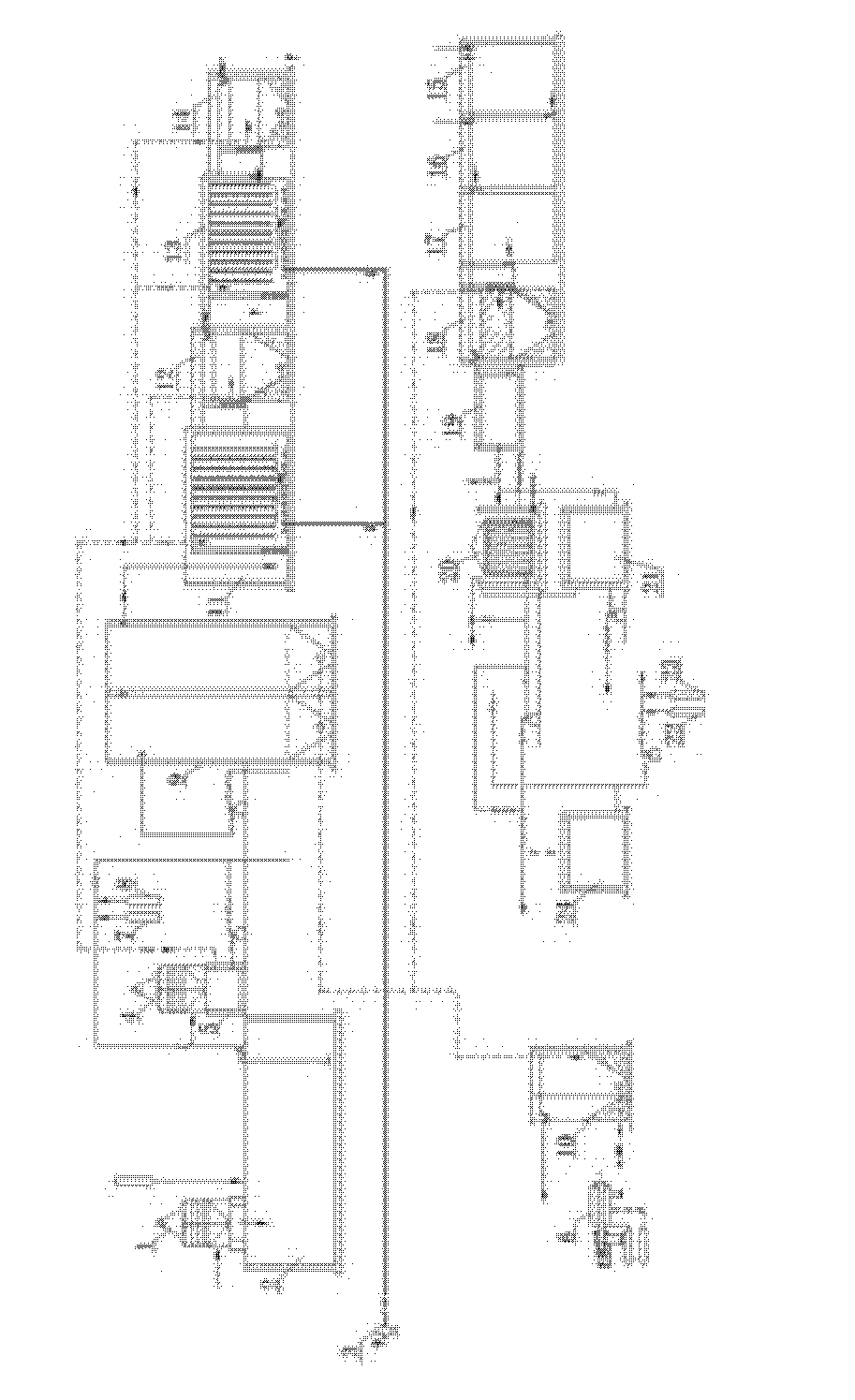

[0020] Such as figure 1 As shown, a new type of PVC mother liquid water treatment equipment, which includes a primary cooling tower 1, a regulating pool 2, a secondary cooling tower 4, a cooling pool 5, an anaerobic pool 9, and a primary biochemical pool 11 connected sequentially through pipelines , primary sedimentation tank 12, secondary biochemical pool 13, secondary sedimentation tank 14, primary reaction tank 15, secondary reaction tank 16, mixing tank 17, coagulation sedimentation tank 18, intermediate pool 19, waste water tank 21, membrane Pool 20 and backwash pool 24, anaerobic pool 9 are also connected with a sludge pool 10 by pipeline, sludge pool 10 is connected with a plate and frame filter press 6, and anaerobic pool 9 is also connected with coagulation sedimentation tank 18. A primary lift pump is arranged between the regulating pond 2 and the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com