Molding mechanism of paper plastic packaging machine

A molding mechanism and packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high processing cost, high cost, large heat-sealing modulus, etc., and achieve easy installation and transportation, low production cost, The effect of small heat seal modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

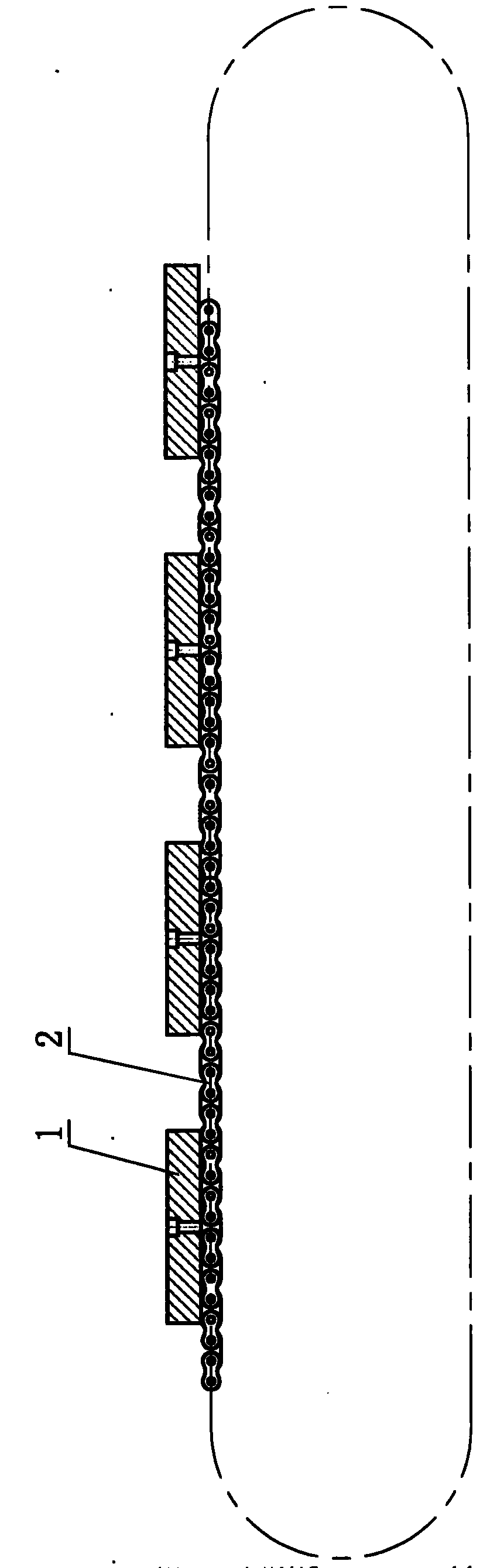

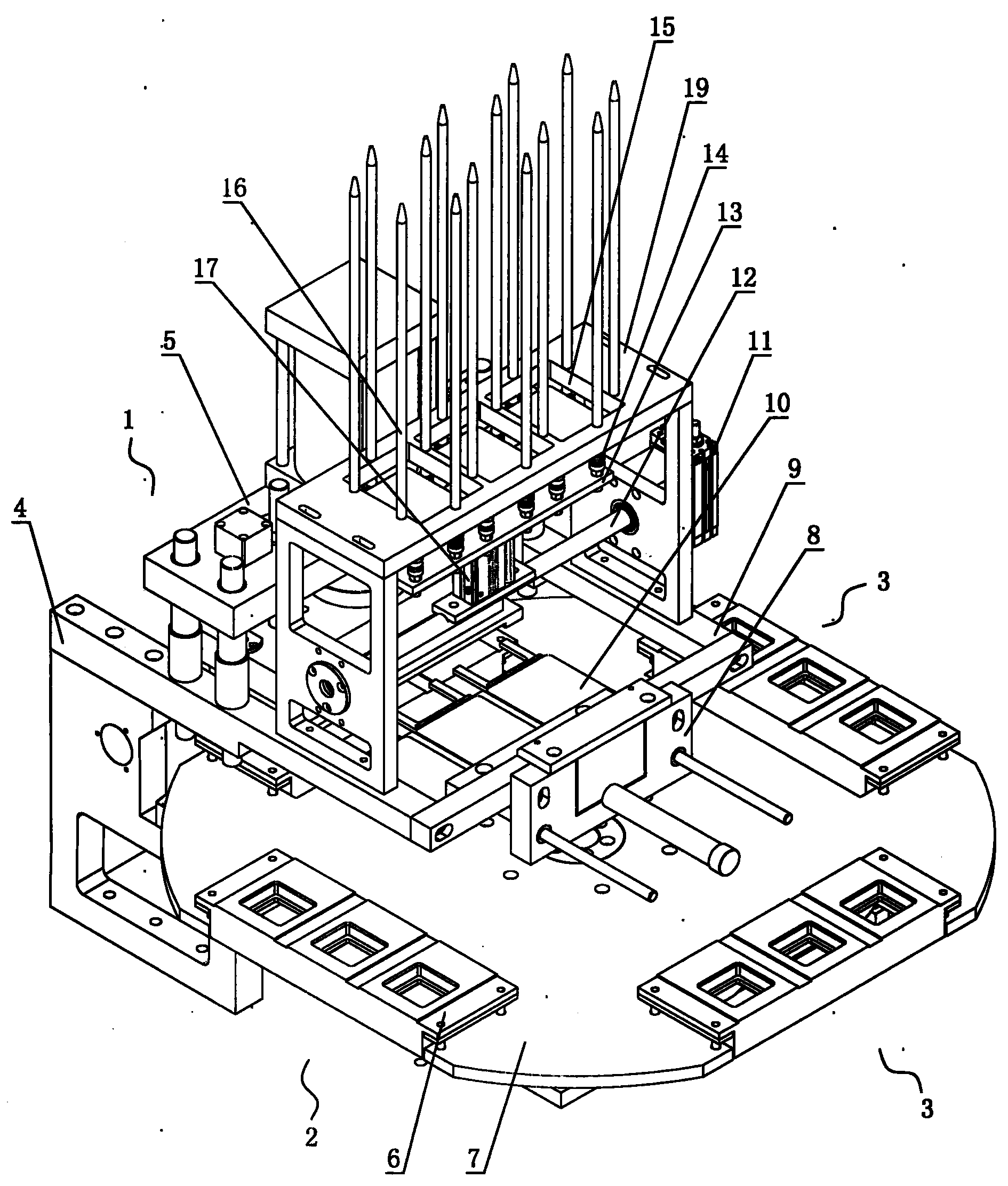

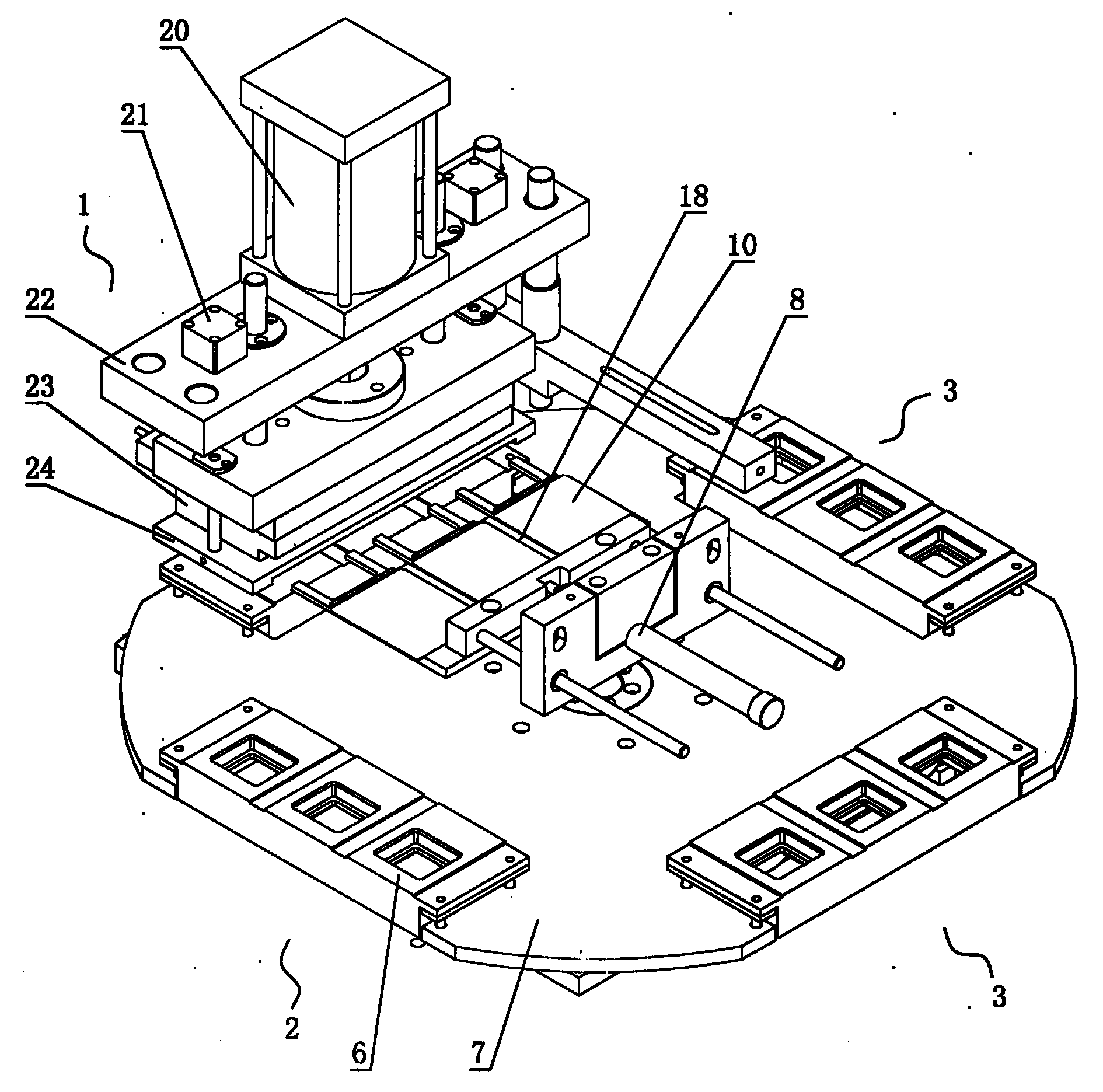

[0023] With reference to the accompanying drawings, the molding mechanism of this kind of paper-plastic packaging machine includes a frame 4, a heat-sealing mold 6, a plastic blister blanking station 2, a feeding station 3 and a heat-sealing station 1, and the heat-sealing station Position 1 is provided with heat-sealing device 5, and described frame 4 is provided with turntable 7, and described turntable 7 is connected with power source, and power source can adopt cylinder or motor, drives turntable to rotate; Described heat-sealing mold 6 has several In this embodiment, there are four heat-sealing molds 6, which are evenly distributed on the turntable 7 along the circumferential direction, and there are two feeding stations 3, and the four heat-sealing molds 6 on the turntable 7 are combined with the plastic The blister blanking station 2, the feeding station 3 and the heat-sealing station 1 correspond one-to-one; the top of the turntable 7 is provided with a cardboard blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com