Preparation method of low thermal expansion carbon fiber reinforced resin matrix composite mold

A reinforced resin-based, low thermal expansion technology, applied in the field of composite material preparation, can solve the problems of high specific stiffness, low thermal expansion, mismatch between thermal expansion coefficient and composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

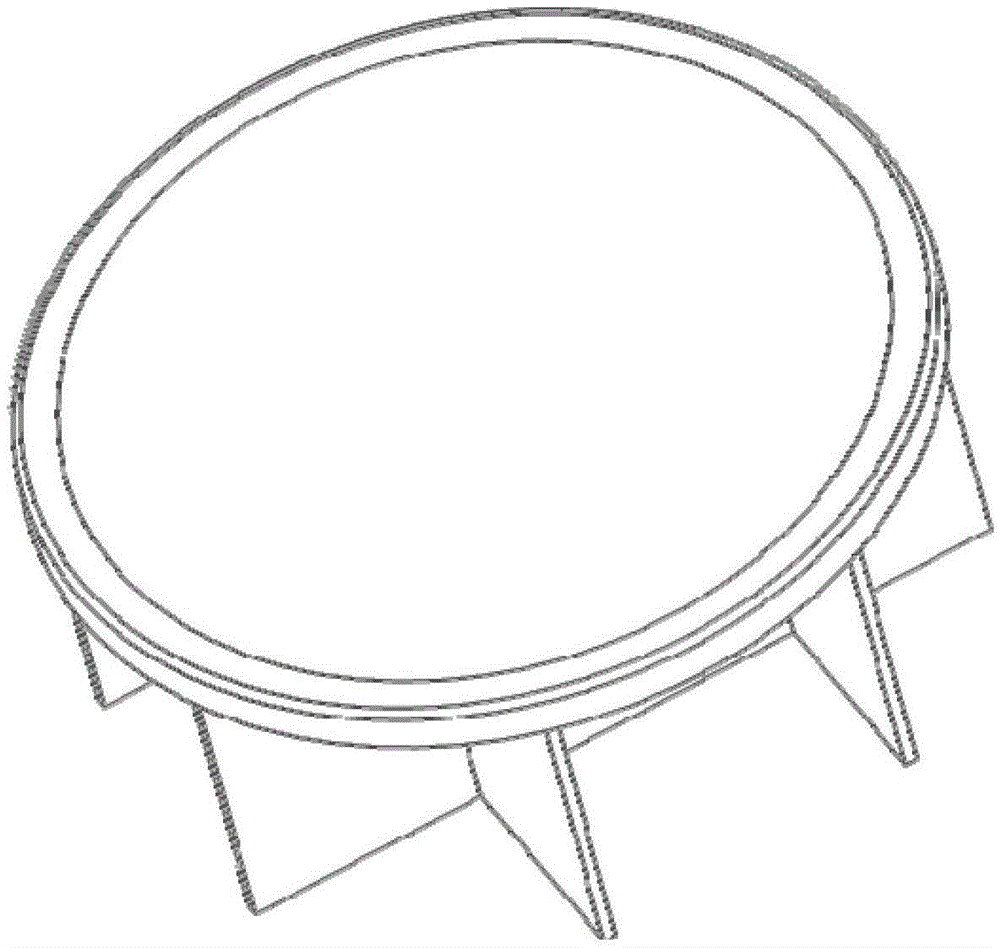

[0031] The example produced is a molding mold required for forming high-precision carbon fiber parabolic products. The diameter of the parabolic projected area is 0.9m, and the profile is an irregular surface. The long-term use temperature of the mold is required to be higher than 150°C, and the linear expansion coefficient of the mold material at 150°C is not greater than 4×10 -6 / K.

[0032] The first step is to design the mold structure:

[0033] Add a 100mm process edge on the periphery of the product to make a vacuum bag when the composite material product is formed. The shape and structure of the mold are as follows figure 2 shown. And design the mold forming master mold, the master mold is a concave mold to ensure the mold surface after molding;

[0034] The second step is to design the surface layer of the mold: according to the thermal expansion coefficient of the mold, it is not greater than 4×10 -6 / K, through finite element analysis modeling, the design surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com