Stiffness-measurement-based optimization method for cylindrical grinding process parameters

A technology of process parameter optimization and cylindrical grinding, which is applied in the direction of machine tools designed for grinding the rotating surface of workpieces, parts of grinding machine tools, grinding/polishing equipment, etc. The vibration stability curve is complex, and the grinding accuracy is not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] The cylindrical grinding process parameter optimization method based on stiffness measurement of the present invention, its steps are:

[0023] 1) Pressure sensor installation and machine tool static stiffness measurement

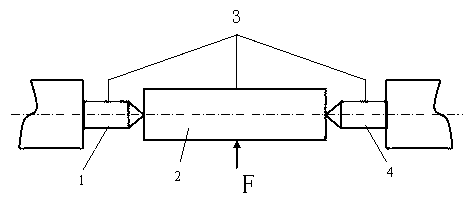

[0024] Such as figure 1 As shown, the installation of the displacement sensor: select the displacement sensor 3 with a measurement resolution of less than 0.1 μm and a protection level of IP65 (waterproof) or above, and install the three displacement sensors 3 on the top of the machine headstock 1, the top of the tailstock 4, and the middle of the workpiece 2 respectively. position, the displacement sensor 3 is used to measure the amount of deformation in the feeding direction of the grinding wheel. The measurement signal is obtained by the computer through the A / D acquisition card.

[0025] Use a hydraulic device to apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com