A method for manufacturing an energy-saving compound nozzle for a diamond drill bit

The invention relates to a technology of a diamond drill bit and a manufacturing method, which is applied to the manufacturing field of energy-saving composite nozzles of diamond drill bits, and can solve the problems of frequent replacement of nozzles, disassembly, non-compliance with low-carbon economy, and high scrap rate of nozzles, so as to reduce the links of sintered tungsten carbide and enhance the toughness. , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

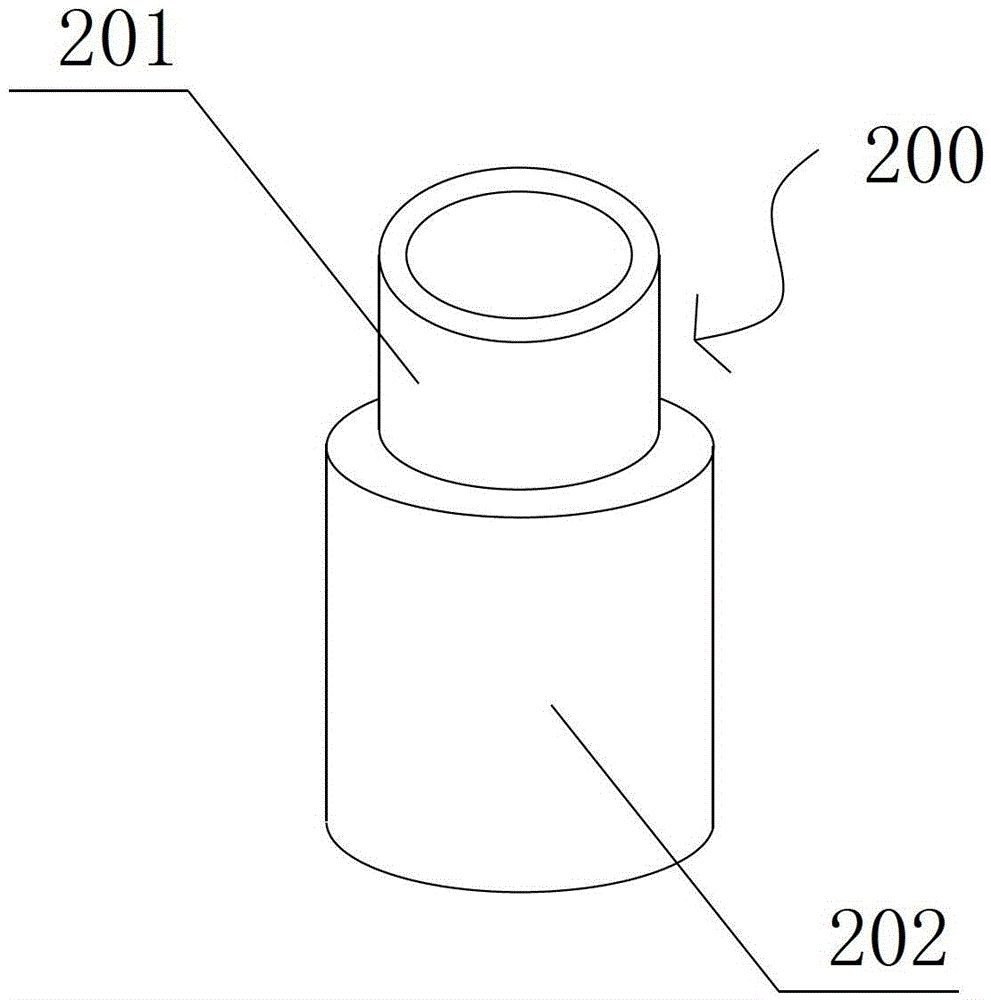

[0028] figure 1 It is a structural schematic diagram of the nozzle base of the present invention, figure 2 It is a structural schematic diagram of the working end base of the present invention, such as figure 1 with 2 Shown: the present invention comprises the steps:

[0029] (1) Process the nozzle base 100: the nozzle base 100 is machined and formed according to the graphic size, the processed nozzle base 100 is divided into upper and lower parts, the upper part is the continuous convex and concave nozzle head 101, and the lower part is the API holding thread 102, the continuous concave-convex nozzle head 101 and the API holding thread 102 are integrally formed, and the nozzle base 100 is a base with a through-hole 103 with a gradually changing inner diameter; Figure 4 . Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com