Mounting clamp of ultrasonic sensor

A technology for installing fixtures and sensors, used in instruments, measuring devices, manufacturing tools, etc., can solve the problems of ultrasonic flowmeter errors, sensors are not in a plane, and cannot be measured, and achieve reliable clamping results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

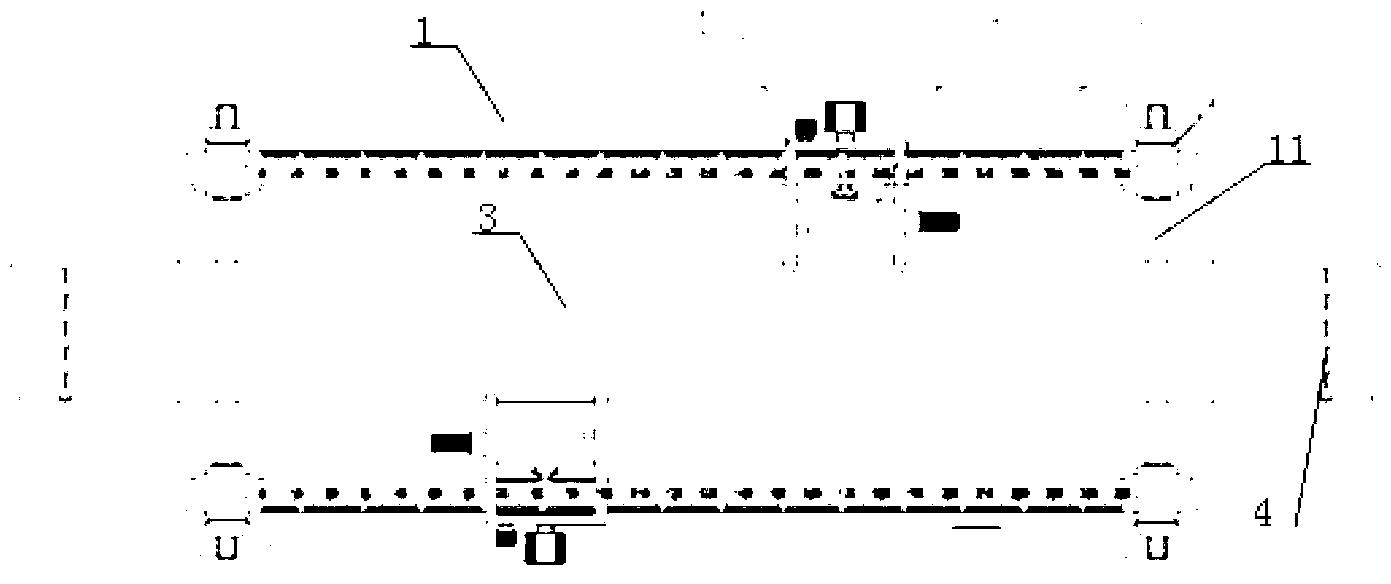

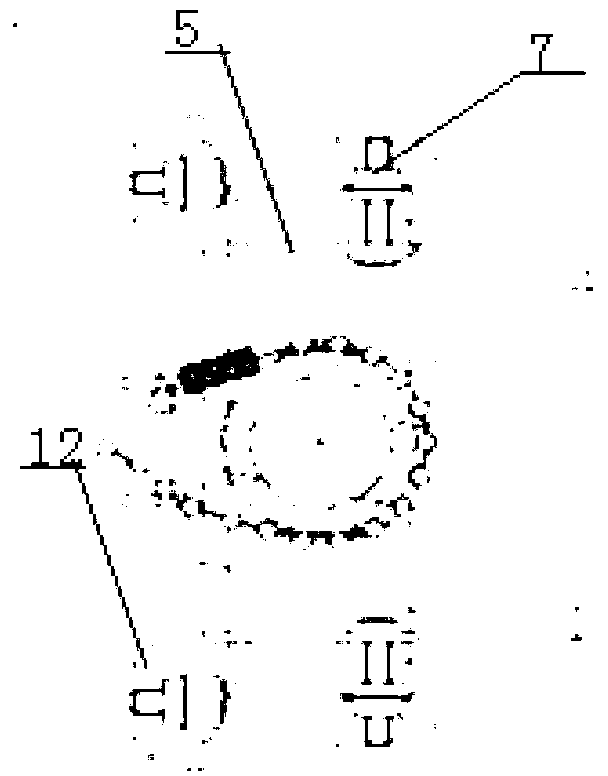

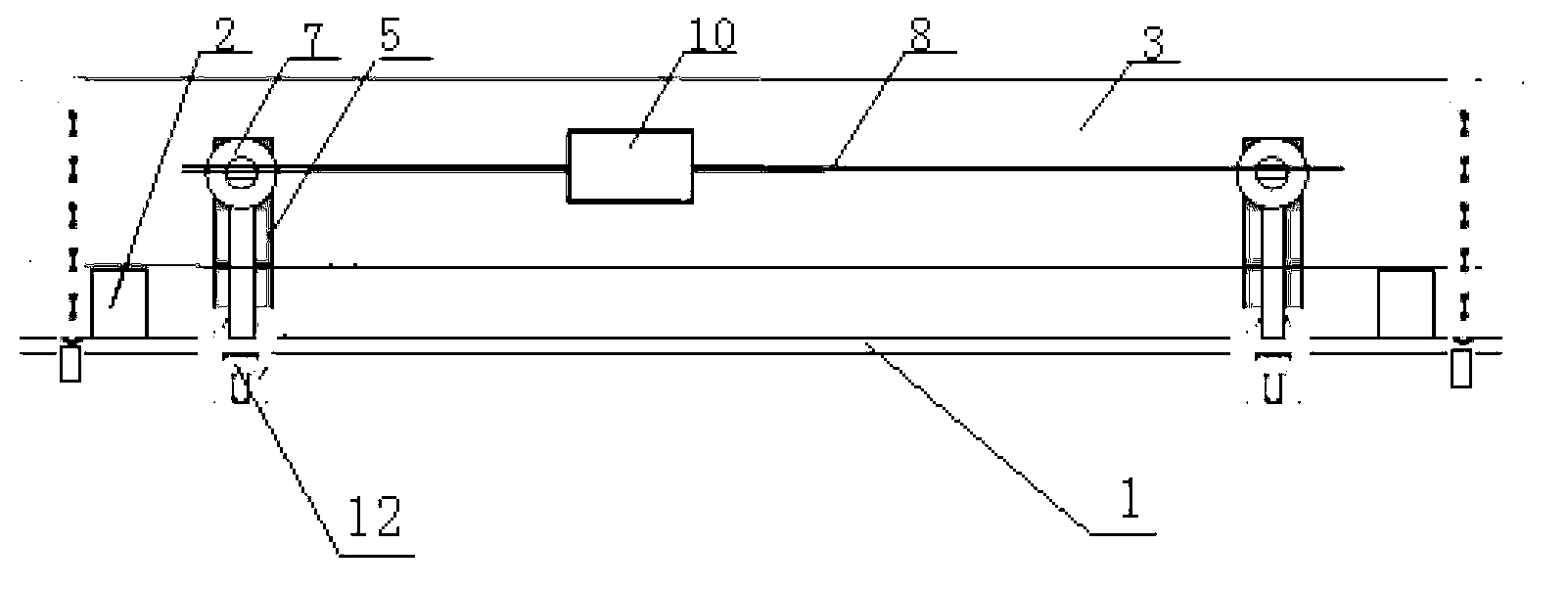

[0011] see figure 1 , figure 2 , image 3 and Figure 4 , An ultrasonic sensor installation jig provided by an embodiment of the present invention includes a mounting plate 1 , a positioning block 2 , a bracket rail 5 , a buckle 7 , a scale slider 8 , and a sensor bracket 10 . The positioning block 2 is fixed on the center line at both ends of the mounting plate 1, and the straight pipe section 3 is positioned by the positioning block 2, which ensures that the datum of the mounting plate 1 is parallel to the straight pipe section 3; the mounting plate 1 is provided with four symmetrical mounting plate tracks 11 , each mounting plate track 11 is connected to the support track 5 through the mounting plate track buckle 12, and the buckle 7 is connected to the chute of the support track 5. By adjusting the distance between the support track 5, the sensor 9 can be used in different pipe diameters. Clamping on the straight pipe section 3, and by adjusting the height of the buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com