Boiler Air Preheater

An air preheater and boiler technology, applied in the field of heat exchanger manufacturing, can solve problems such as low heat transfer coefficient, and achieve the effects of high tube wall temperature, improved heat transfer coefficient, and reduced fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

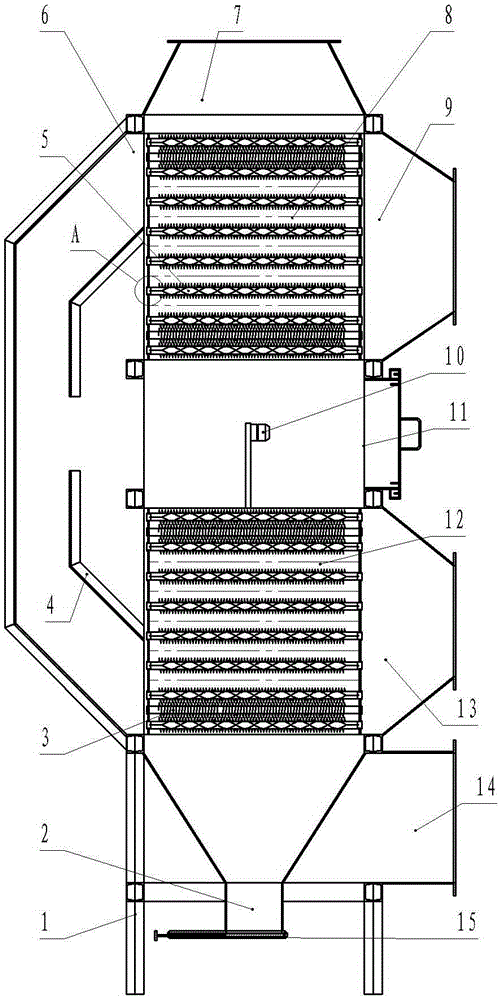

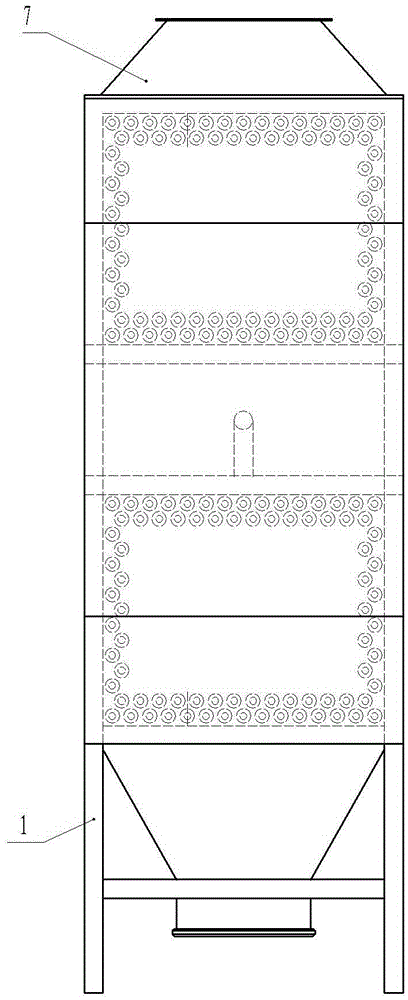

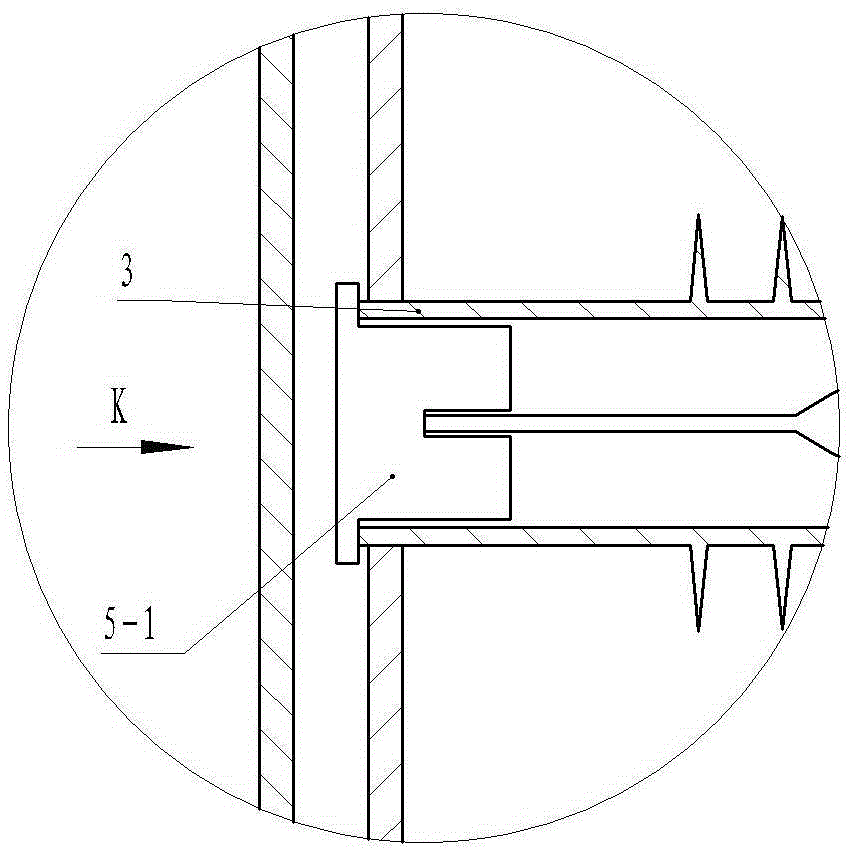

[0020] Such as figure 1 and 2 The shown boiler air preheater includes a heat exchanger shell 11 installed on a bracket 1, a flue gas inlet 7 is installed on the upper part of the heat exchanger shell 11, and a gas inlet 7 is installed on one side of the lower part of the heat exchanger shell 11 There is a flue gas outlet 14, and a heat exchange tube box is installed in the heat exchanger shell 11. The heat exchange tube box has an upper heat exchange tube box 8 equipped with an air outlet 9 and a lower heat exchange tube box 12 equipped with an air inlet 13, Both the upper heat exchange tube box 8 and the lower heat exchange tube box 12 have a plurality of heat exchange tubes 3 inserted between two mounting plates, the outer surface of each tube, and the fins distributed on the outer surface of the tube wall of the heat exchange tubes 3 It is distributed in a spiral; each heat exchange tube 5 is inserted with a spoiler subassembly 5; the spoiler subassembly 5 includes positio...

Embodiment 2

[0023] The thickness of the torsion pieces of the spoiler 5-2 is 3 mm, the pitch H is 120 mm, and the twist rate is 3; each heat exchange tube 3 a is a bare tube; other features are the same as those in Embodiment 1.

[0024] When the dust content in the flue gas is high, in order to prevent and control dust accumulation, the light pipe is selected as the heat exchange tube 3a, and the heat exchange tube 3a is inserted with a spoiler subassembly 5; although the heat transfer coefficient outside the tube is lower than that of the tube wall Finned heat exchange tubes are distributed on the outer surface of the boiler, but the total heat transfer coefficient is still much higher than that of the existing boiler air preheater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com