A kind of all-peripheral sealing gasket and its production process

A technology of gaskets and inner holes, which is applied in the field of full-circumference gaskets and its production technology, can solve the problems of increased production costs, large labor demand, and low work efficiency, and achieve the effects of cost saving, labor reduction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

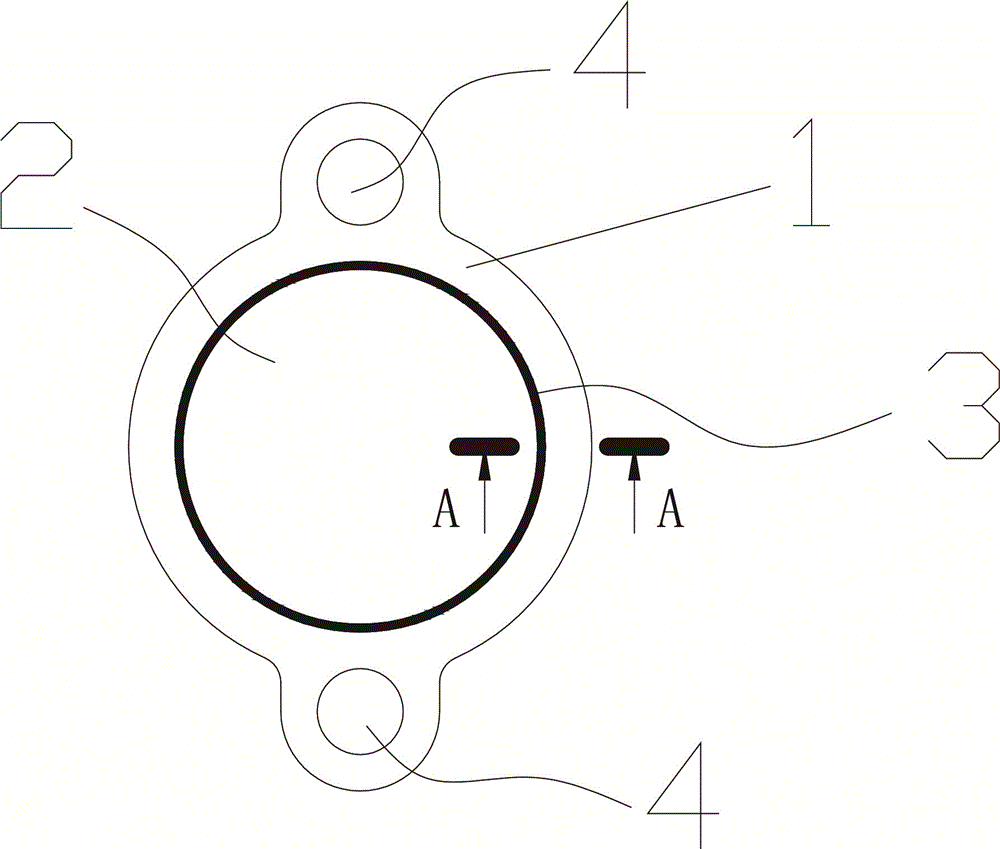

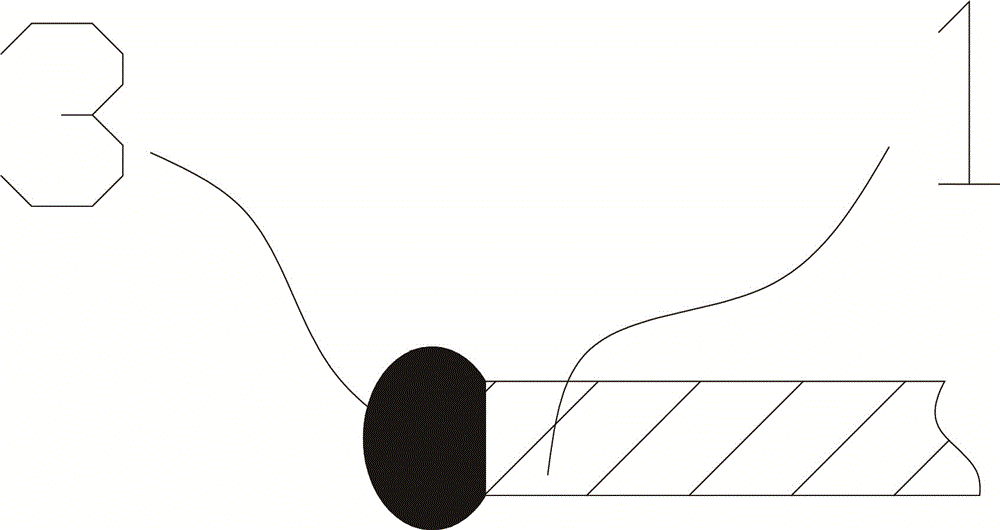

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 with figure 2 , a full-circumferential sealing gasket, including a body 1, the body 1 is made of pressed non-asbestos material, and can also be made of other composite materials. In this embodiment, non-asbestos material is used. The thickness of the main body 1 is 0.5mm-1.0mm.

[0013] The edge of the inner hole 2 of the main body 1 is uniformly coated with adhesive glue on the edge of the inner hole 2 of the main body 1 by means of rotary dipping, and then the adhesive layer 3 is formed by baking at a drying temperature and gasket separation technology. The glue layer 3 is firmly bonded to the edge of the inner hole 2 of the body 1, so that the body 1 and the glue layer 3 are tightly bonded together. The glue coated on the edge of the inner hole 2 can be silica gel, fluorine rubber, nitrile rubber, etc., preferably silica ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com