Gas-assisted urea injection system with mixing tube heating method adopted

A technology of a urea injection system and a heating method, which is applied in the design field of urea injection system for vehicles, can solve the problems of affecting exhaust back pressure and engine performance, difficult to arrange the structure of the whole vehicle, etc., so as to facilitate the layout of the whole vehicle and reduce the exhaust pipe. Road manufacturing process cost and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

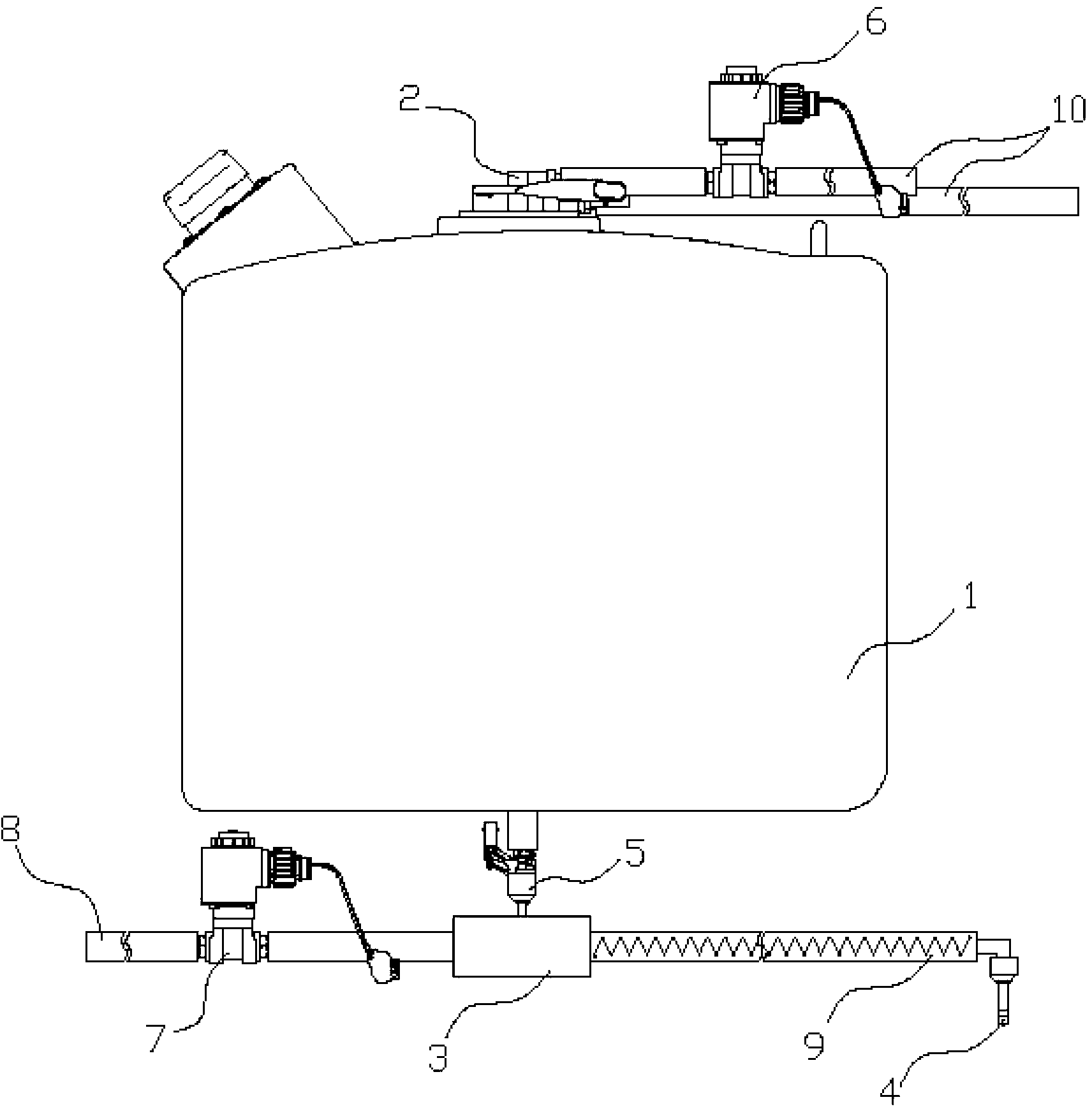

[0011] Such as figure 1 Shown is a gas-assisted urea injection system using a mixing tube heating method, which includes a urea tank 1, a urea tank temperature and liquid level sensor 2, a heating control valve 6 for heat exchange in the urea tank, and a heating water pipe 10. A urea metering valve 5 separate from the nozzle 4 is installed at the bottom of the urea metering valve 5. The lower end of the urea metering valve 5 is connected with a mixing chamber 3. One end of the mixing chamber 3 is connected with a gas control valve 7 and a gas pipe 8, and the other end is connected with a heating mixing pipe 9 and a nozzle. 4 pipeline connections.

[0012] The heating source of the heating mixture pipe 9 can be electricity or engine exhaust.

[0013] The heating pipe can be a hose or a metal pipe, as long as it can withstand urea aqueous solution and high temperature below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com