Stainless steel low-temperature powder-embedded iron-aluminum co-infiltration agent and embedding infiltration process method

A powder embedding, stainless steel technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of low aluminum content in the aluminized layer and low aluminum content in the outermost layer, and achieve strong bonding strength, good protection effect, good resistance to medium temperature oxidation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

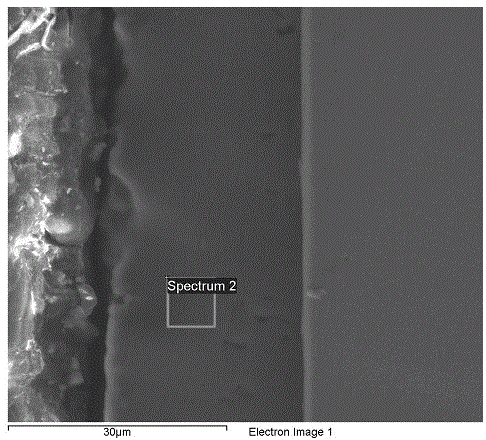

Image

Examples

Embodiment 1

[0027] Aluminizing agent composition (weight):

[0028] 30% aluminum powder (Al, 200 mesh), 3% iron powder (Fe, 200 mesh), 36% iron-aluminum powder (Fe-Al, 150 mesh), 30% aluminum trichloride (AlCl 3 ), 1% lanthanum powder (La);

[0029] Processing technology:

[0030] (1) Derust and degrease the surface of the workpiece that needs iron-aluminum co-infiltration treatment, and dry it for later use;

[0031] (2) Mix the above-mentioned penetrating agent components uniformly and then dry them in a vacuum environment below the decomposition temperature of aluminum trichloride; dry the dry-treated penetrating agent with iron-aluminum co-infiltration treatment and have been carried out The pre-treated stainless steel workpieces are placed in the infiltration tank, and sealed with refractory mud mixed with water glass. After drying and solidification, iron-aluminum co-infiltration treatment is carried out in the SX2-4-10 box-type resistance furnace. The method of entering the fu...

Embodiment 2

[0034] Aluminizing agent composition (weight):

[0035] 30% aluminum powder (Al, 200 mesh), 5% iron powder (Fe, 200 mesh), 60% iron-aluminum powder (Fe-Al, 150 mesh), 5% aluminum trichloride (AlCl 3 ).

[0036] Treatment process: (1) Derust and degrease the surface of the workpiece that needs iron-aluminum co-infiltration treatment, and dry it for later use;

[0037] (2) Mix the above-mentioned penetrating agent components uniformly and then dry them in a vacuum environment below the decomposition temperature of aluminum trichloride; dry the dry-treated penetrating agent with iron-aluminum co-infiltration treatment and have been carried out The pre-treated stainless steel workpieces are placed in the infiltration tank, and sealed with refractory mud mixed with water glass. After drying and solidification, iron-aluminum co-infiltration treatment is carried out in the SX2-4-10 box-type resistance furnace. The method of entering the furnace is cold charging, and the cooling m...

Embodiment 3

[0040] Aluminizing agent composition (weight):

[0041] 30% aluminum powder (Al, 200 mesh), 7% iron powder (Fe, 200 mesh), 41% iron-aluminum powder (Fe-Al, 150 mesh), 20% aluminum trichloride (AlCl 3 ), 1% cerium trichloride (CeCl 3 ), 1% lanthanum powder (La).

[0042] Processing technology:

[0043] (1) Derust and degrease the surface of the workpiece that needs iron-aluminum co-infiltration treatment, and dry it for later use;

[0044] (2) Mix the above-mentioned penetrating agent components uniformly and then dry them in a vacuum environment below the decomposition temperature of aluminum trichloride; dry the dry-treated penetrating agent with iron-aluminum co-infiltration treatment and have been carried out The pre-treated stainless steel workpieces are placed in the infiltration tank, and sealed with refractory mud mixed with water glass. After drying and solidification, iron-aluminum co-infiltration treatment is carried out in the SX2-4-10 box-type resistance furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com